Wormwood or mint extract modified polyamide fiber and preparation method thereof

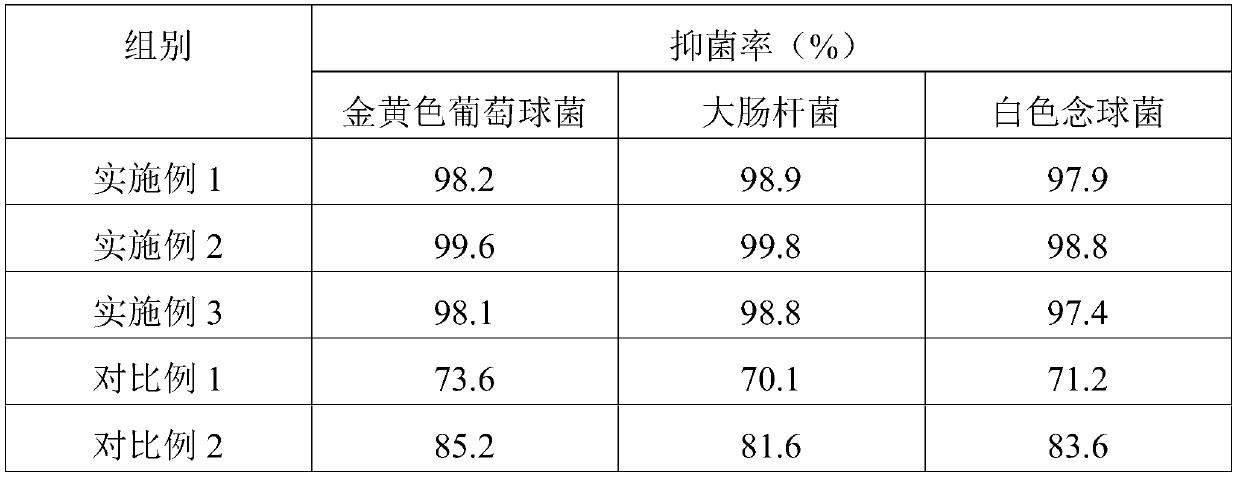

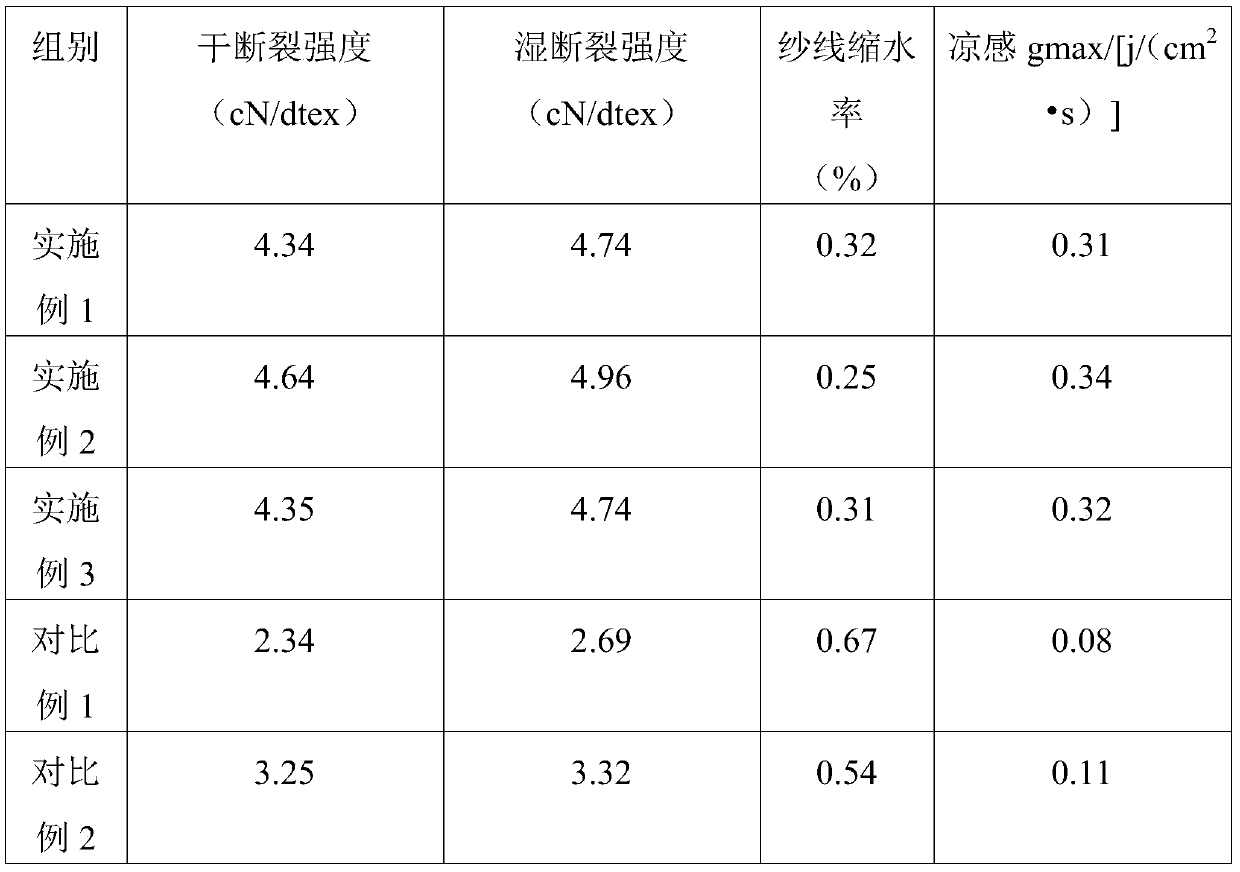

A technology of mint extract and nylon fiber, which is applied in the textile field, can solve the problems of affecting the antibacterial performance of finished fibers, affecting the performance of fiber mechanics, and reducing the antibacterial performance of wormwood or mint fibers, so as to achieve uniform performance and reduce yarn shrinkage , Improve the effect of antibacterial rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The modified nylon fiber of the wormwood extract of the present embodiment, first, the wormwood extract is modified, and the modified method includes the following steps:

[0037] (1) Take an appropriate amount of water and heat it to 55°C, add the wormwood extract, the mass ratio of water to wormwood extract is 1:12, stir and dissolve evenly to obtain a mixed solution, the bath ratio is 1:14;

[0038] (2) Add montmorillonite and zeolite powder to the mixed solution, the total mass ratio of wormwood extract to montmorillonite and zeolite powder is 1:6, and the mass ratio of montmorillonite and zeolite powder is 1 : 1, stirring and mixing evenly, the stirring speed is 30r / min, and the stirring time is 100min to obtain the modified nanocomposite material containing the wormwood extract.

[0039] The preparation method of the wormwood extract modified nylon fiber of the present embodiment comprises the steps:

[0040] (a) Preparation of functional masterbatch: sequentiall...

Embodiment 2

[0043] A kind of peppermint extract modified nylon fiber of the present embodiment, at first, carry out modification treatment to peppermint extract, the method for modification comprises the following steps:

[0044] (1) Take an appropriate amount of water and heat it to 60°C, add the peppermint extract, the mass ratio of water to peppermint extract is 1:15, stir and dissolve evenly to obtain a mixed solution, the bath ratio is 1:15;

[0045] (2) Porous nano-TiO 2 Microspheres and zeolite powder are added to the mixed solution, peppermint extract and porous nano TiO 2 The mass ratio of the microspheres was 1:7.5, and the mixture was uniformly stirred, the stirring speed was 45r / min, and the stirring time was 70min to obtain a modified nanocomposite material containing peppermint extract.

[0046] The preparation method of the peppermint extract modified nylon fiber of the present embodiment may further comprise the steps:

[0047](a) Preparation of functional masterbatch: s...

Embodiment 3

[0050] A kind of mugwort extract modified nylon fiber of the present embodiment, first, carry out modification treatment to mugwort extract, the modification method comprises the following steps:

[0051] (1) Take an appropriate amount of water and heat it to 65°C, add the wormwood extract, the mass ratio of water to wormwood extract is 1:18, stir and dissolve evenly to obtain a mixed solution, the bath ratio is 1:18;

[0052] (2) Porous nano-SiO 2 Microspheres are added to the mixed solution, and the wormwood extract and porous nano-SiO 2 The mass ratio of the microspheres was 1:9, and the mixture was uniformly stirred, the stirring speed was 60r / min, and the stirring time was 40min, to obtain a modified nanocomposite material containing wormwood extract.

[0053] The preparation method of the wormwood extract modified nylon fiber of the present embodiment comprises the steps:

[0054] (a) Preparation of functional masterbatch: slice 100kg of nylon 66, 0.3kg of zinc stearat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com