A kind of hyperbranched organosilicon wetting agent for aqueous polyurethane and preparation method thereof

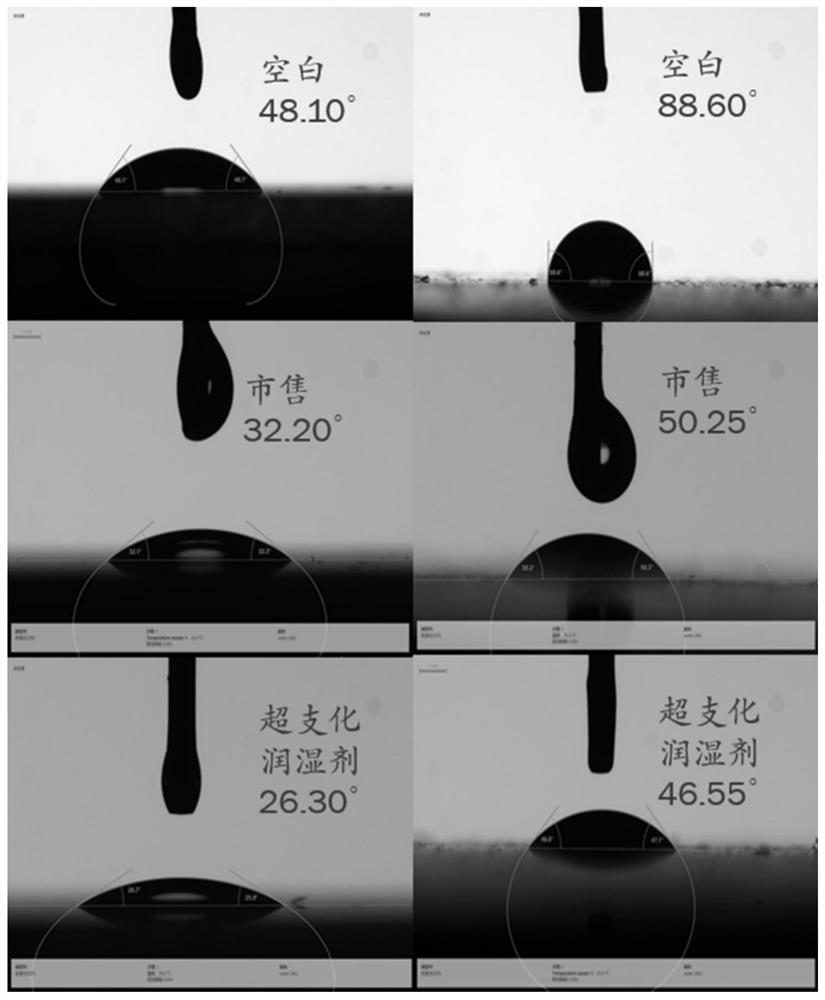

A water-based polyurethane and silicone technology, which is applied in the field of synthetic leather chemical industry and leather, can solve unseen problems, achieve low viscosity, excellent ability to reduce surface tension, and high surface activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

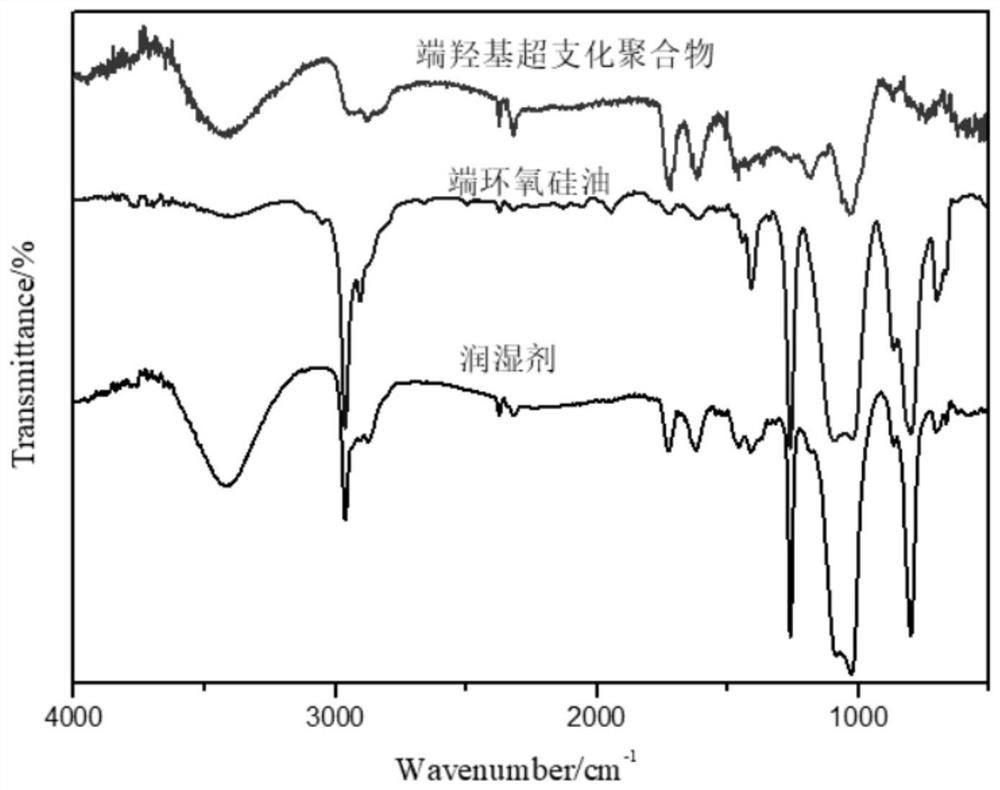

Image

Examples

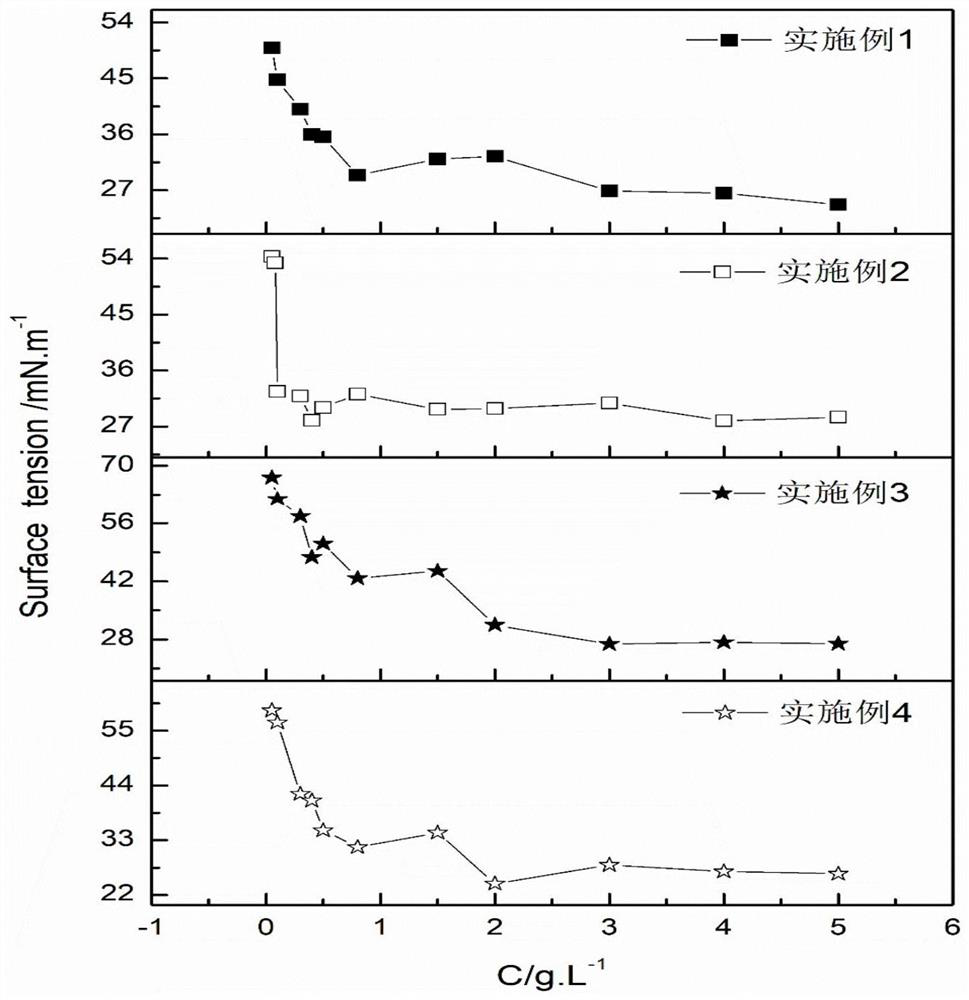

Embodiment 1

[0039] After the addition was weighed in a dry, clean and good 250mL three-neck flask 42.10g of diethanolamine DEA 10mL of methanol and the mixture was stirred for twenty diethanolamine DEA completely dissolved at room temperature with a stirring rod, MA methyl acrylate was poured into a solution of 69.087g tube then the three-necked flask equipped with a stir bar frame, and a condenser tube was added dropwise to a bath of oil, will begin at 35 ℃ methacrylate MA three-necked flask was slowly added dropwise, IH dropwise addition, the reaction incubated 4h and then subjected to suction filtration with vacuum suction machine circulating water to remove methanol and excess methyl acrylate MA obtained as a colorless transparent oil AB 2 Type monomers. The obtained monomer into a clean glass container for use.

[0040] P-toluenesulfonic acid, the preparation was added 17.89g trimethylolpropane TMP 0.48g and dried in a clean three-neck flask 70.23gAB 2 Monomer was poured into the droppin...

Embodiment 2

[0043] After the addition was weighed in a dry, clean and good 250mL three-neck flask 42.11g of diethanolamine DEA 10mL of methanol and the mixture was stirred for twenty diethanolamine DEA completely dissolved at room temperature with a stirring rod, was poured into the solution of 69.1g of methyl acrylate MA tube then the three-necked flask equipped with a stir bar frame, and a condenser tube was added dropwise to a bath of oil, will begin at 35 ℃ methacrylate MA three-necked flask was slowly added dropwise, IH dropwise addition, the reaction incubated 4h and then subjected to suction filtration with vacuum suction machine circulating water to remove methanol and excess methyl acrylate MA obtained as a colorless transparent oil AB 2Type monomers. The obtained monomer into a clean glass container for use.

[0044] P-toluenesulfonic acid, the preparation was added 17.94g trimethylolpropane TMP and 0.649g in dry and clean three-neck flask 72gAB 2 Monomer was poured into the droppin...

Embodiment 3

[0047] After the addition was weighed in a dry, clean and good 250mL three-neck flask 42.12g of diethanolamine DEA 10mL of methanol and the mixture was stirred for twenty diethanolamine DEA completely dissolved at room temperature with a stirring rod, was poured into the solution of 69.1g of methyl acrylate MA tube then the three-necked flask equipped with a stir bar frame, and a condenser tube was added dropwise to a bath of oil, will begin at 35 ℃ methacrylate MA three-necked flask was slowly added dropwise, IH dropwise addition, the reaction incubated 4h and then subjected to suction filtration with vacuum suction machine circulating water to remove methanol and excess methyl acrylate MA obtained as a colorless transparent oil AB 2 Type monomers. The obtained monomer into a clean glass container for use.

[0048] P-toluenesulfonic acid, the preparation was added 17.79g trimethylolpropane TMP and 0.645g in dry and clean three-neck flask 73.24gAB 2 Monomer was poured into the dro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com