A kind of anti-crack finish layer of cement concrete member and preparation method thereof

A cement concrete and finishing layer technology, which is applied in the field of cement concrete products, can solve the problems of increasing the difficulty of technical control, complex production and construction technology, and waste of cost, so as to improve workability and surface decoration effects, reduce construction costs, and improve components. The effect of crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

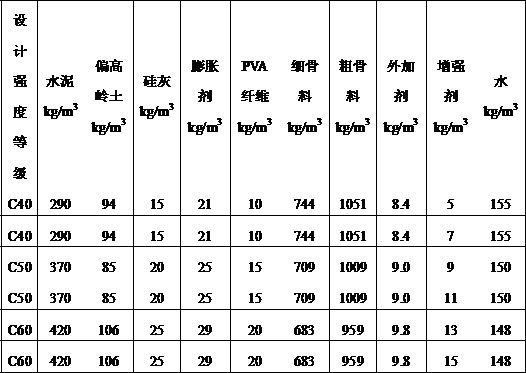

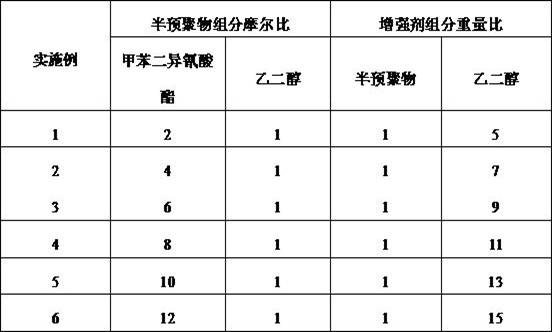

Embodiment 1~6

[0036] In Examples 1-6, the cement adopts Conch brand P.O42.5 cement, and the apparent density is 3070 kg / m 3 , the 28d compressive strength is 48.4MPa; the silica fume is made of Sichuan Langtian encrypted silica fume, and the apparent density is 2180 kg / m 3 , SiO 2 Content 94%, specific surface area 15800m 2 / kg, 28d activity 115%; expansion agent is three-source HEA type, water reduction rate 13%, 21d limit expansion rate in air -0.02%; polyvinyl alcohol (PVA) fiber adopts Guangheng Chemical high-strength high-modulus fiber, fiber length 12 mm, elastic modulus 36GPa, elongation 8%, tensile strength 1600MPa; fine aggregate is Xiangtan quartz machine-made sand, fineness modulus 2.8; coarse aggregate is Loudi limestone gravel, particle size is 5-20mm, The crushing value is 8.5%; the water is tap water; the admixture is a high-performance polycarboxylic acid admixture from China Construction Western Construction New Material Technology Co., Ltd., and the formulas of each comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com