Clinker drying device for cement processing

A drying device and clinker technology, which is applied in the field of cement processing, can solve the problems of affecting the drying effect and uneven heating of clinker, so as to improve the drying effect, avoid excessive pressure, and ensure the drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

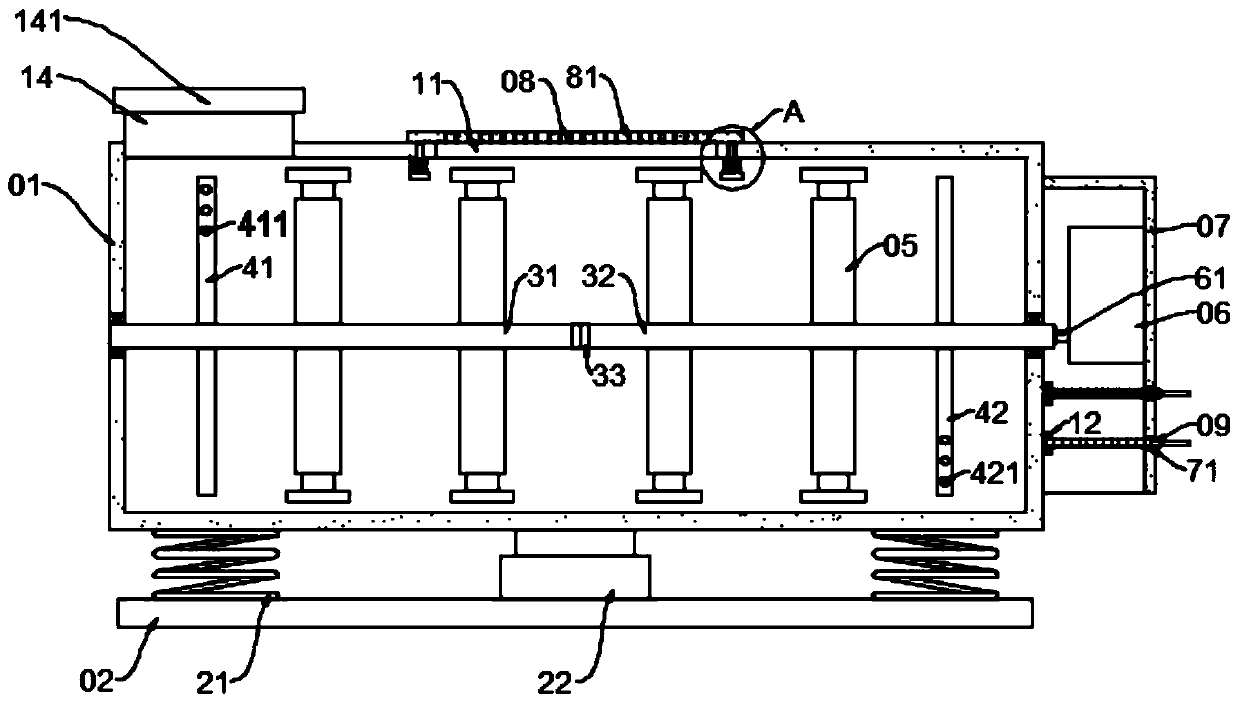

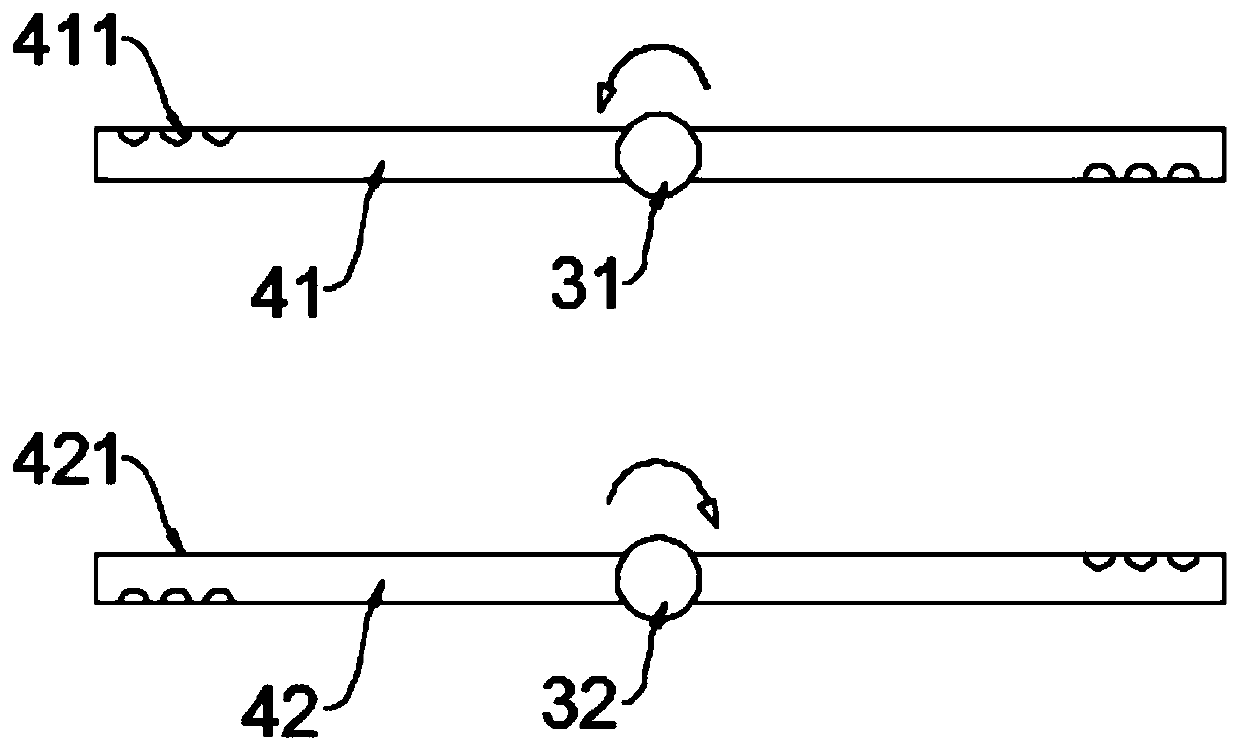

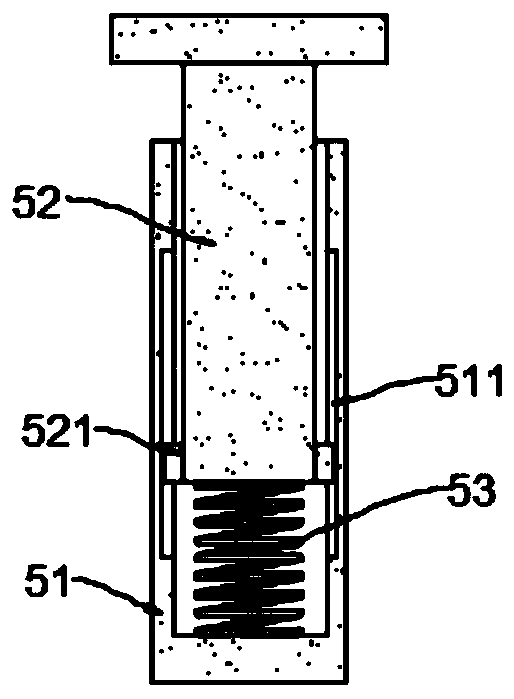

[0026] see Figure 1~3 , in an embodiment of the present invention, a clinker drying device for cement processing includes a box body 01, a base 02 and a hot air blower 06, and a feed pipe 14 is connected to the top shell wall of the box body 01, and the feed pipe 14 A feed pipe valve 141 is installed on the top; a horizontal hollow shaft is arranged in the box body 01, and the hollow shaft is rotatably connected in the box body 01, and a material turning member 05 and a plurality of sets of feeding parts perpendicular to the hollow shaft are fixed on the hollow shaft. Air pipes, the number of the air pipes in each group is two and air holes are provided on the air pipes; the output end of the hot air blower 06 is connected with an air supply pipe 61, and the air supply pipe 61 is connected with the hollow rotating shaft through a rotating joint. During work, The hot air generated by the hot air blower 06 is ejected through the air holes, and the hollow rotating shaft will rot...

Embodiment 2

[0036] see figure 1 , 4 ~5, the embodiment of the present invention expands the function on the basis of embodiment 1, specifically:

[0037] The top shell wall of the box body 01 is provided with an exhaust hole 11, and the exhaust hole 11 is provided with a baffle plate 08, and the baffle plate 08 is evenly distributed with micropores 81. During operation, the excess heat in the box body 01 passes through The discharge speed of the micropores 81 is relatively slow, so that the pressure in the box 01 is increased, and the drying efficiency is improved.

[0038]In order to ensure the safety of the work, in this embodiment, the bottom of the baffle plate 08 is fixed with a vertically arranged guide rod 82, and the guide rod 82 slides through the perforation 13 opened in the top shell wall of the box body 01. The guide rod 82 The limit block 821 is fixed at the bottom of the bottom, and a resistance spring 822 is connected between the limit block 821 and the inner wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com