Landfill leachate concentrated solution adsorption, fermentation, dehydration and solidification process

A landfill leachate and landfill leachate technology are applied in the field of landfill leachate concentrated liquid adsorption, fermentation, dehydration and solidification process, which can solve the problems of increased processing cost, complicated fixed assets investment equipment, and the government and enterprises cannot afford it, and achieve a good economy. Benefit and social benefits, improve the environmental protection standard water effluent rate, and improve the effect of permeate concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the implementation technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

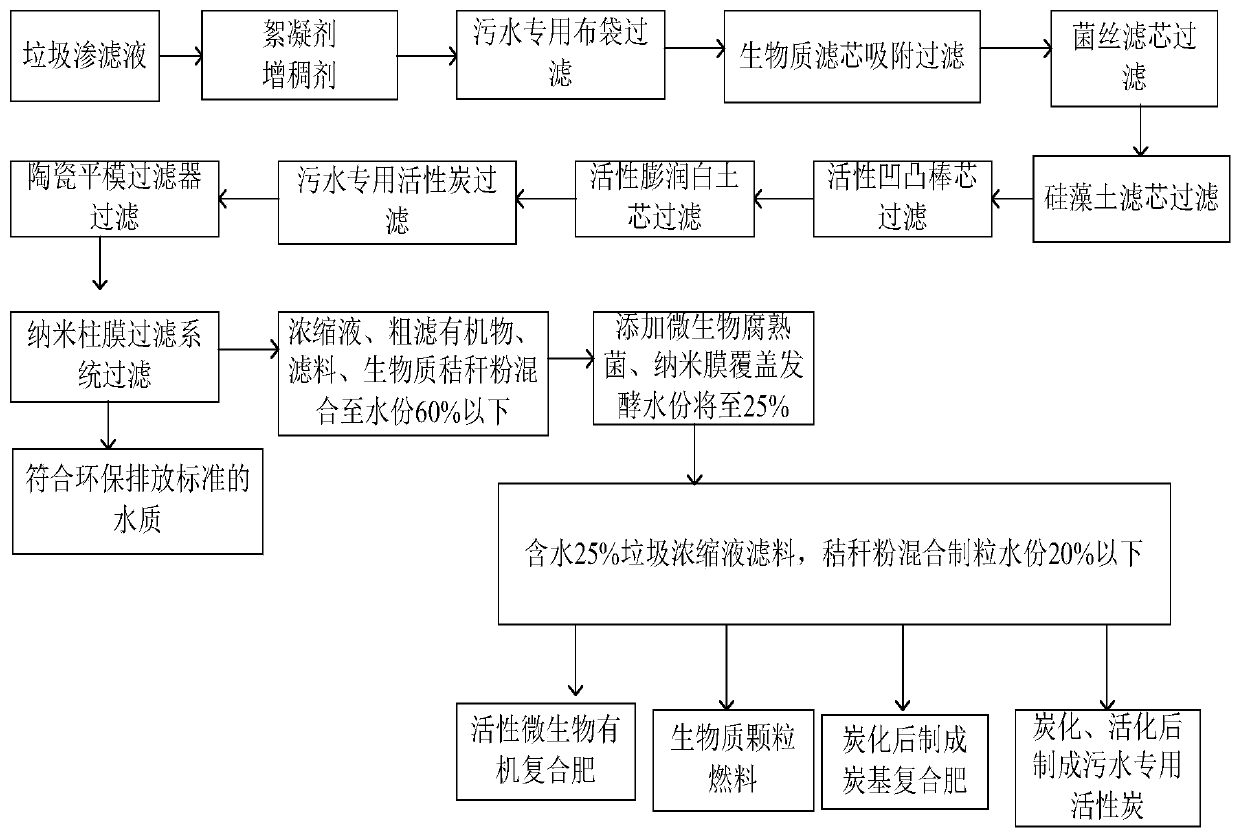

[0032] Such as figure 1 As shown, a solidification process of adsorption, fermentation, dehydration and solidification of landfill percolation concentrate includes coarse filtration, fine filtration, mixing, fermentation, granulation, and carbonization steps. By adding biomass straw and using microbial decomposing agent to ferment and naturally dehydrate, it can produce National standard microbial organic fertilizer, carbon-based compound fertilizer, biomass fuel and activated carbon for sewage treatment. To achieve the purpose of treating waste with waste and turning waste into treasure.

[0033] Its main steps are as follows:

[0034] Step 1, coarse filtration: first add flocculant and thickener to the landfill leachate, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com