Cloth roll wrapping positioning device and cloth inspecting roll wrapping machine

A positioning device and wrapping technology, applied in the directions of transportation and packaging, winding strips, and thin material processing, can solve the problems that the cloth cannot be formed into a cylinder, the cloth cannot be accurately rolled, and the labor force is increased, and the connection structure is achieved. Simple and novel, simple and novel structure, good curl positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

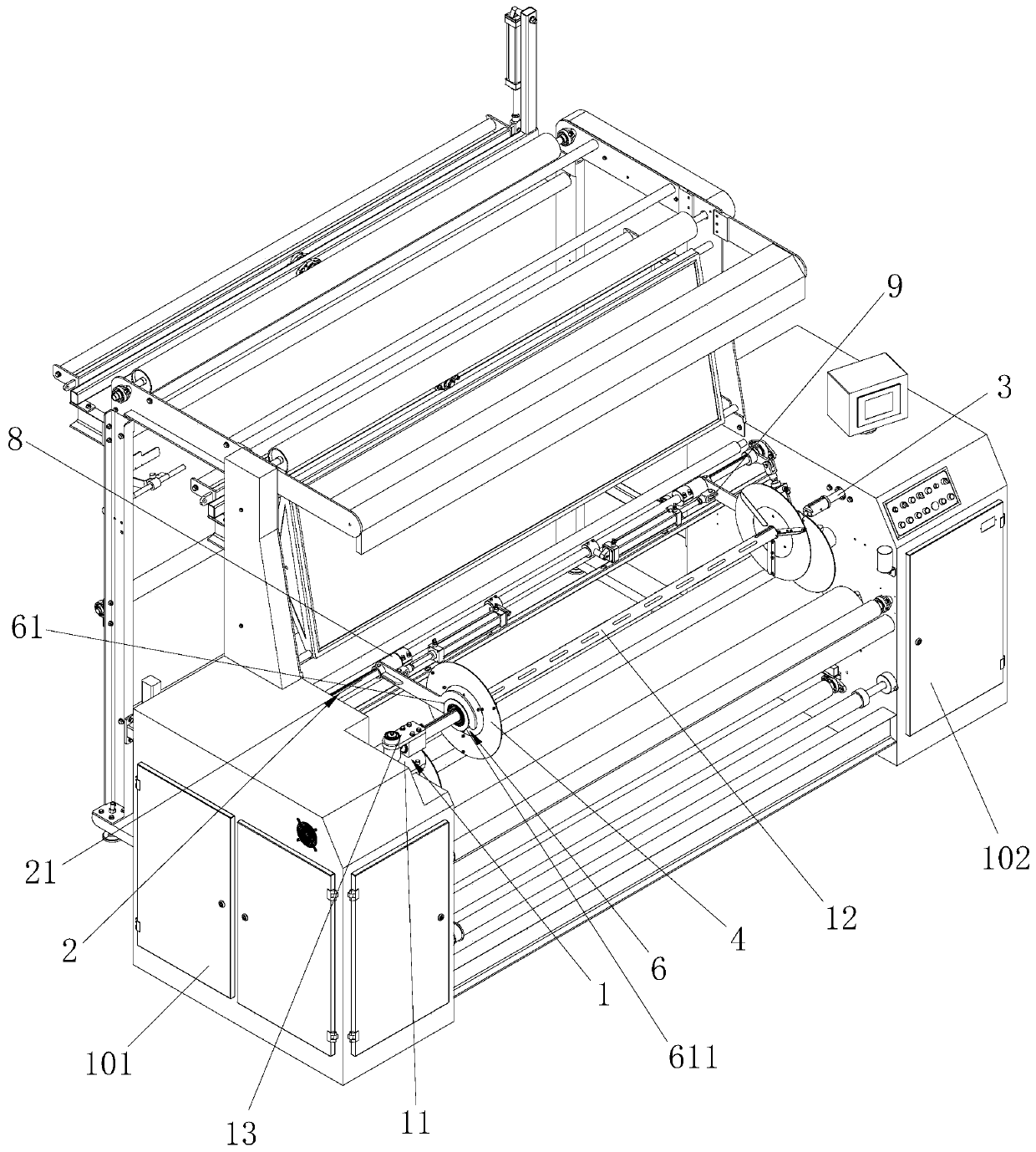

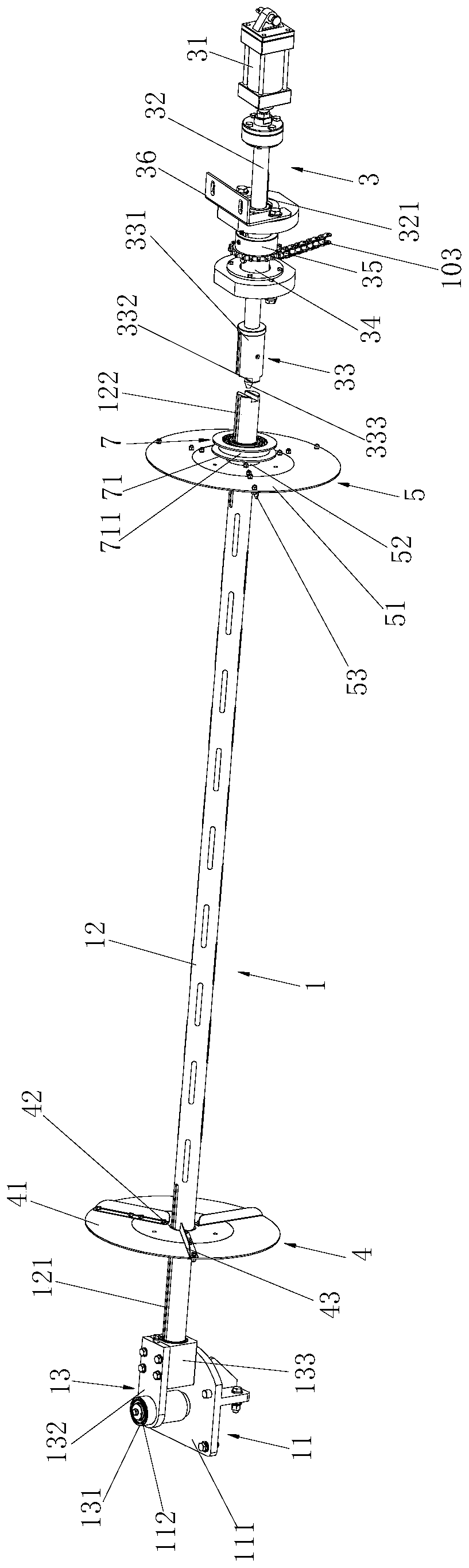

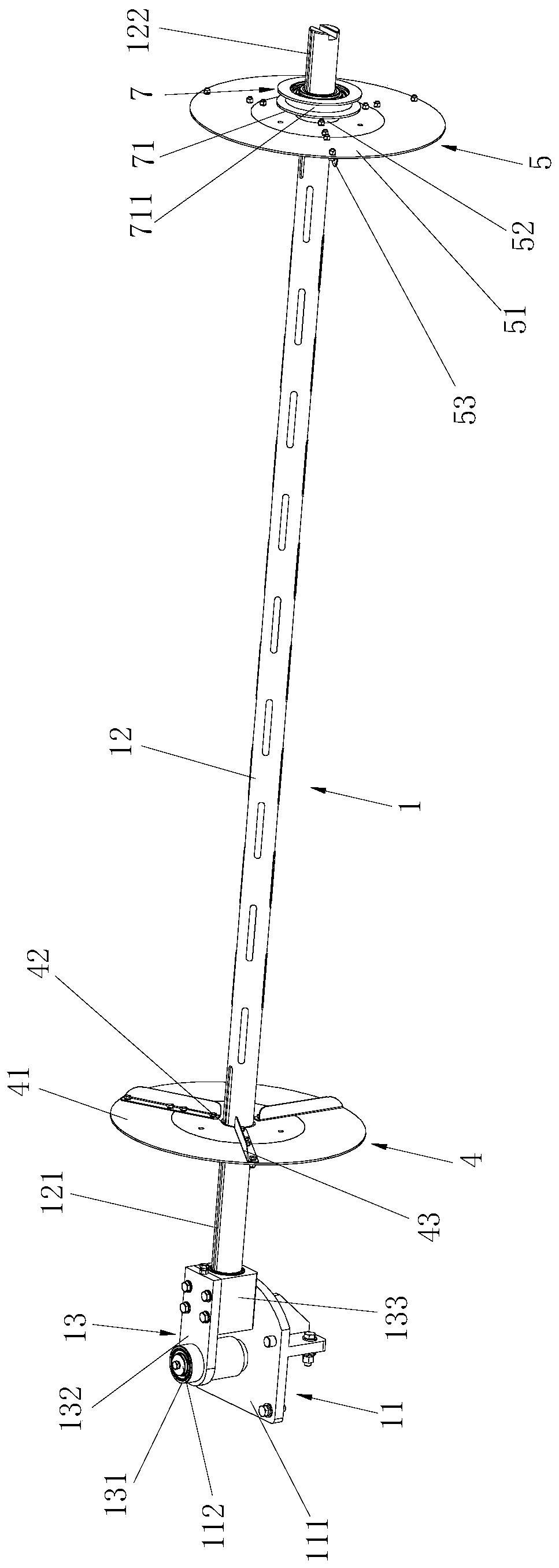

[0053] combine Figure 1 to Figure 5 , a cloth wrapping positioning device, including a cloth rolling mechanism 1, a toggle mechanism 2 and a transmission mechanism 3, the cloth rolling mechanism includes an air expansion shaft fixing seat 11 and an air expansion shaft rod 12, and the air expansion shaft fixing seat 11 passes through the rotating arm assembly 13 is connected with one end of the air expansion shaft 12, the first cloth roll clamping assembly 4 and the second cloth roll clamping assembly 5 are positioned on the air expansion shaft 12, and the outer end of the first cloth roll clamping assembly 4 is connected to There is a first toggle adapter assembly 6, and a second toggle adapter assembly 7 is connected to the outer end of the second cloth clamping assembly 5.

[0054] The toggle mechanism 2 comprises a swing shaft 21, a first cylinder 22, a first main toggle assembly 8 and a second main toggle assembly 9, one end of the swing shaft 21 is connected with a first...

Embodiment 2

[0088] combine Figure 1 to Figure 5 , a cloth inspection and wrapping machine, including a left casing 101 and a right casing 102, and also includes the above-mentioned cloth wrapping positioning device, which is connected between the left casing 101 and the right casing 102. When the cloth wrapping positioning device is connected, the air shaft fixing seat 11 is fixed on the left casing 101 by bolts.

[0089] The transmission mechanism 3 includes a second cylinder 31 and a transmission shaft 32 connected to the second cylinder 31. The transmission shaft 32 is connected to the other end of the air expansion shaft 12 through a telescopic shaft joint 33. The transmission shaft 32 is covered with a transmission shaft. The axle sleeve 34 is fixedly connected with the transmission sprocket 35 outside the transmission axle sleeve 34.

[0090]The second cylinder 31 in the transmission mechanism 3 is arranged in the right casing 102, and the inner wall of the right casing 102 is pro...

Embodiment 3

[0092] combine Figure 1 to Figure 5 , when the above-mentioned cloth inspection and wrapping machine is working normally, the cloth is transferred to the cloth wrapping positioning device through the transmission system in the cloth inspection and wrapping machine to complete the wrapping of the cloth. When wrapping the cloth, the first main toggle assembly 8 in the toggle mechanism 2 drives the first fabric clamping assembly 4 to slide leftward on the inflatable shaft 12 through the first toggle adapter assembly 6 , the second main toggle assembly 9 drives the second roll cloth clamping assembly 5 to slide on the telescopic shaft joint 33 through the second toggle adapter assembly 7 .

[0093] Then the first air cylinder 22 works to drive the swing shaft 21 to rotate upwards. During the rotation of the swing shaft 21, it drives the first main toggle assembly 8 and the second main toggle assembly 9 to rotate. The first main toggle assembly 8 and the first The toggle adapter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com