Cobweb-like microstructure broach with gradient wetted surface and preparation method thereof

A surface gradient and microstructure technology, applied in broaching, broaching, manufacturing tools, etc., can solve the problems of waste, poor wetting performance of cutting fluid, etc., and achieve the effect of improving service life, improving wettability, and protecting tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

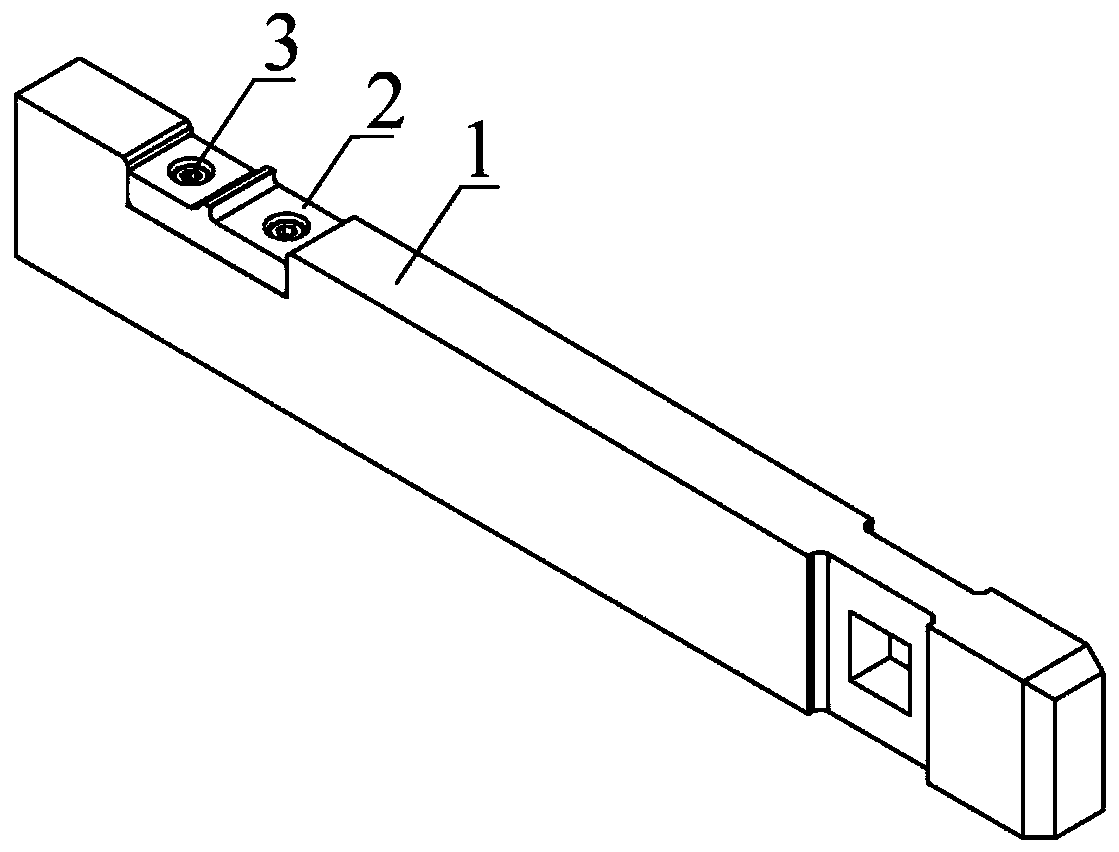

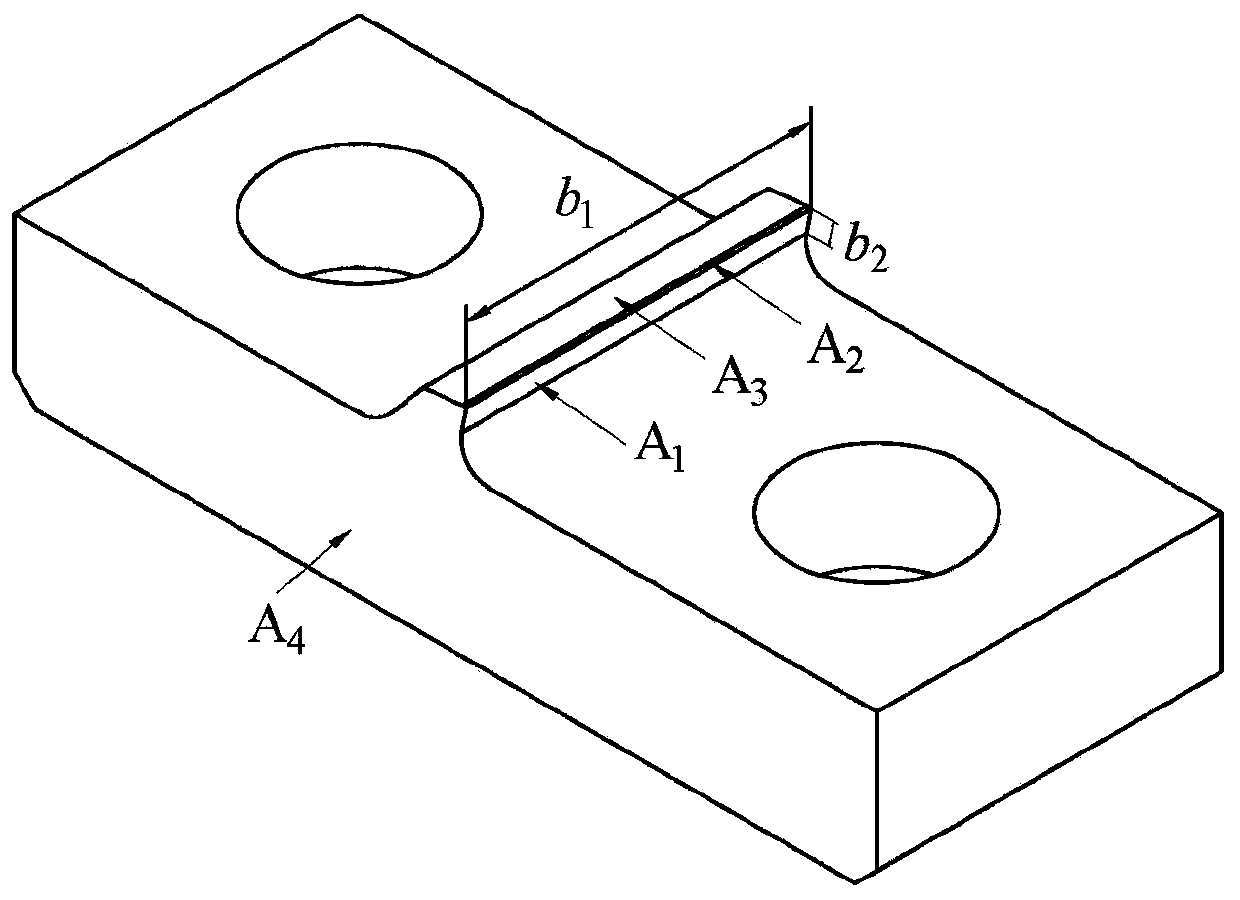

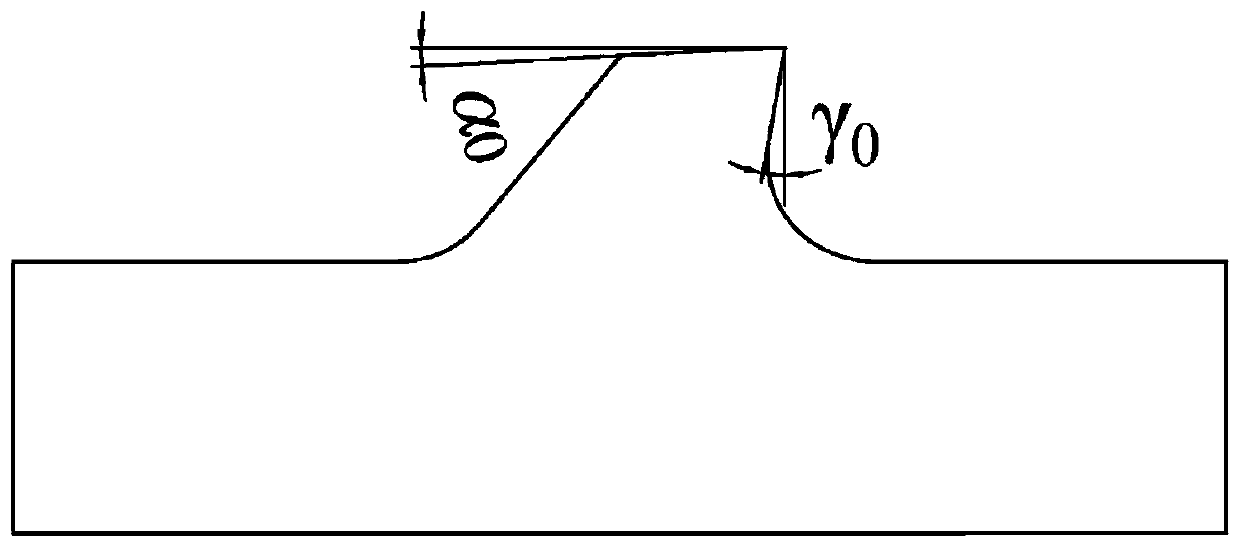

[0040] Such as figure 1 , 2As shown in and 3, a broach with a surface gradient wetting imitation spider web microstructure includes a tool base 1 and a tooth block 2. The cutter body of the cutter base 1 is provided with cutter tooth installation slots. The cutter block 2 is fixed in the cutter tooth installation groove on the cutter base 1 by two bolts 3 . The total length of the cutter base 1 is 400mm, and the width is 16mm; the cutter block 2 is provided with broach cutter teeth. The broach teeth are located between the two bolts 3 . The tooth width b1 of the broach tooth is 16mm, the rake face width b2 is 2mm, the rake angle γ0 of the knife tooth is 12°, and the relief angle α0 is 6°. The broach tooth is provided with a rake face A1, a blade A2 and a flank face A3.

[0041] Such as figure 2 , 4 and 5; the rake face A of the broach tooth 1 A spider web-like microstructure is provided on the top; the spider-web microstructure includes m transverse grooves and n long...

Embodiment 2

[0061] The difference between this embodiment and Embodiment 1 lies in that: a plurality of cutter tooth installation slots are opened on the cutter base body, and a plurality of cutter tooth blocks are installed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com