Double-layer composite water electrolysis anode catalyst and preparation method thereof

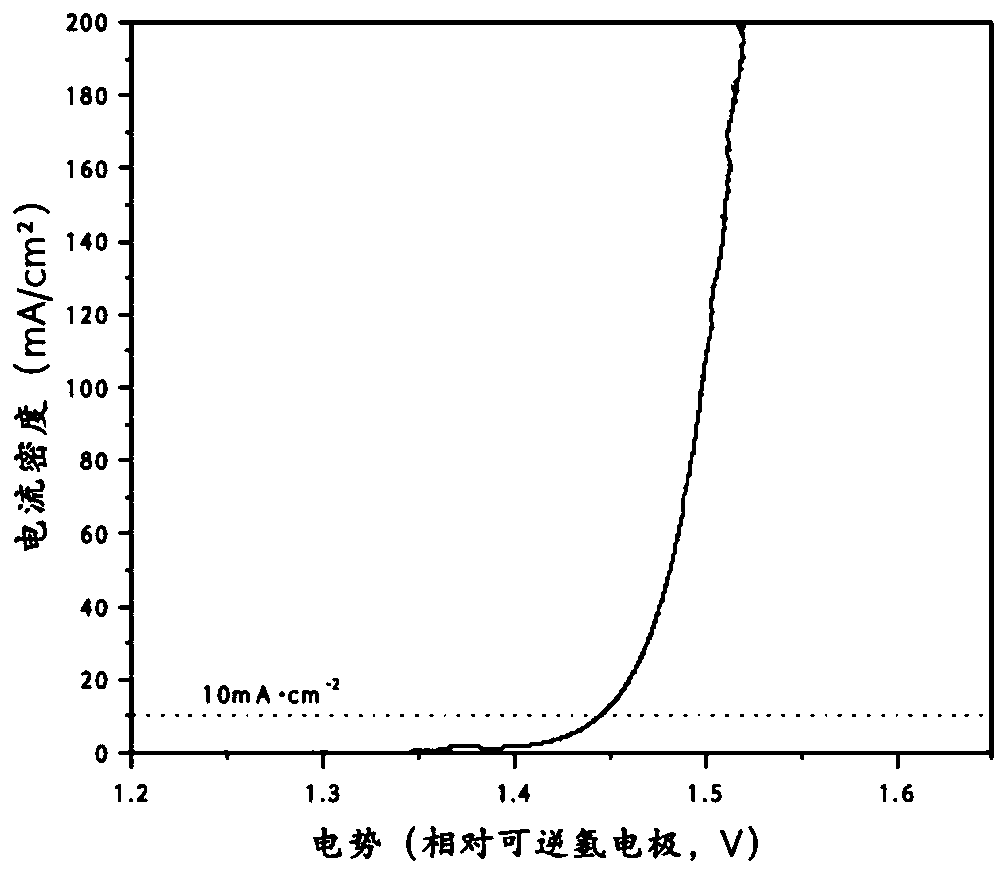

A double-layer composite, electrolyzed water technology, used in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of high price and difficult practical application, and achieve simple preparation methods and long-term stability. , the effect of large hollow volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing a double-layer composite electrolytic water anode catalyst, comprising the following steps:

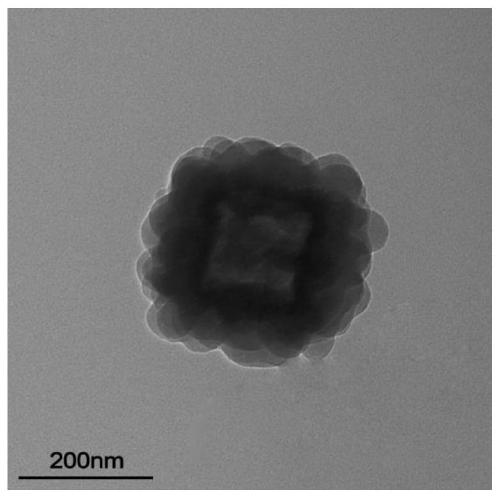

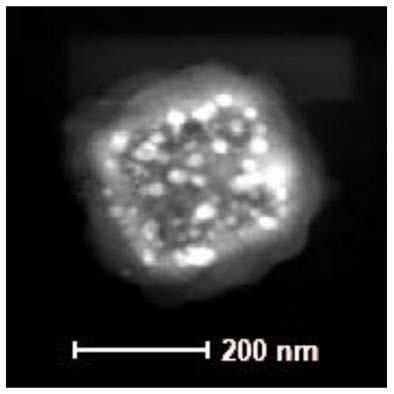

[0037] (01) Weigh 0.15g of cobalt(II) acetate tetrahydrate and 0.147g of trisodium citrate dihydrate and dissolve them in 40mL of deionized water with magnetic stirring for 2min to form solution A. In addition, 0.132 g of potassium hexacyanoferrate (III) was weighed and dissolved in 60 mL of deionized water and magnetically stirred for 2 min to form solution B. Under magnetic stirring, solution B was uniformly added to solution A within 15s, and the stirring was continued for 1min, and then the resulting mixture was transferred and aged at 80°C for 6h. Finally, the samples were collected by centrifugation, washed by deionized water and ethanol, and dried overnight at 70 °C to obtain Prussian blue-like nanomaterials.

[0038] (02) Weigh 0.5 g of CTAB and dissolve it in 20 mL of deionized water with magnetic stirring for 2 min to obtain an aqueous CTAB sol...

Embodiment 2

[0044] A method for preparing a double-layer composite electrolytic water anode catalyst, comprising the following steps:

[0045] (01) Weigh 0.15g of cobalt(II) acetate tetrahydrate and 0.147g of trisodium citrate dihydrate and dissolve them in 40mL of deionized water with magnetic stirring for 2min to form solution A. In addition, 0.132 g of potassium hexacyanoferrate (III) was weighed and dissolved in 60 mL of deionized water and magnetically stirred for 2 min to form solution B. Under magnetic stirring, solution B was uniformly added to solution A within 15s, and the stirring was continued for 1min, and then the resulting mixture was transferred and aged at 80°C for 6h. Finally, the samples were collected by centrifugation, washed by deionized water and ethanol, and dried overnight at 70 °C to obtain Prussian blue-like nanomaterials.

[0046] (02) Weigh 0.5 g of CTAB and dissolve it in 20 mL of deionized water with magnetic stirring for 2 min to obtain an aqueous CTAB sol...

Embodiment 3

[0052] A method for preparing a double-layer composite electrolytic water anode catalyst, comprising the following steps:

[0053] (01) Weigh 0.15g of cobalt(II) acetate tetrahydrate and 0.147g of trisodium citrate dihydrate and dissolve them in 40mL of deionized water with magnetic stirring for 2min to form solution A. In addition, 0.132 g of potassium hexacyanoferrate (III) was weighed and dissolved in 60 mL of deionized water and magnetically stirred for 2 min to form solution B. Under magnetic stirring, solution B was uniformly added to solution A within 15s, and the stirring was continued for 1min, and then the resulting mixture was transferred and aged at 80°C for 6h. Finally, the samples were collected by centrifugation, washed with deionized water and ethanol, and dried overnight at 70°C to obtain Prussian blue-like nanomaterials.

[0054] (02) Weigh 0.5 g of CTAB and dissolve it in 20 mL of deionized water with magnetic stirring for 2 min to obtain an aqueous CTAB so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com