Thick steel plate having excellent low-temperature strain-aging impact properties and manufacturing method thereof

A technology of strain aging and impact characteristics, applied in the field of thick steel plate and its manufacturing, which can solve the problems of increased cold deformation, decreased toughness and reduced use environment temperature, and achieved excellent low temperature strain aging impact characteristics and excellent yield strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0063] Hereinafter, the present disclosure will be described more specifically through examples. However, the following examples should be descriptive only

[0065] After preparing molten steel with the alloy compositions shown in Table 1, a continuous casting operation was used to produce billets. put the billet in

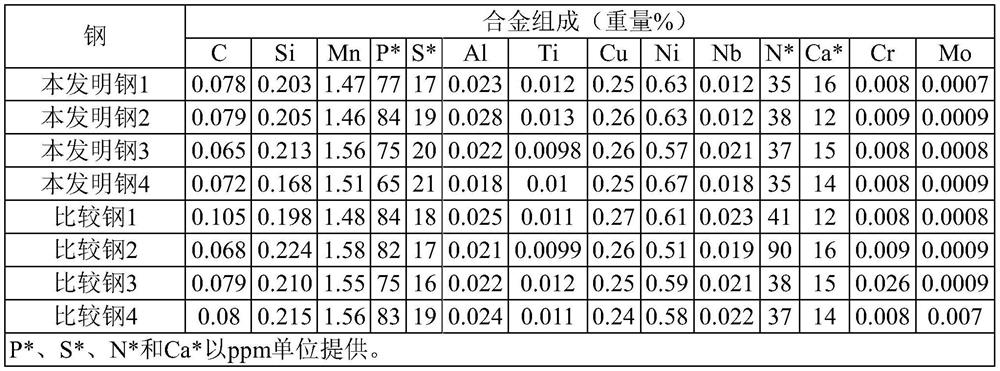

[0066] [Table 1]

[0067]

[0069]

[0070] [Table 3]

[0071]

[0074] The recrystallization zone rolling operation was performed in two passes for the width control of the product after the alloy composition was satisfied, and the

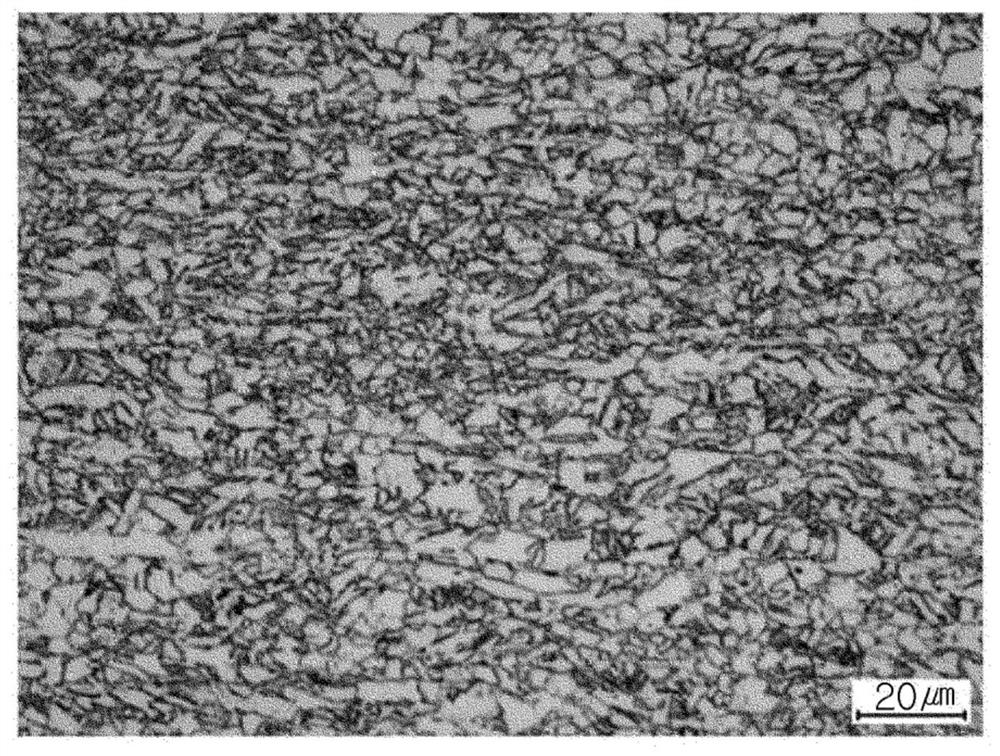

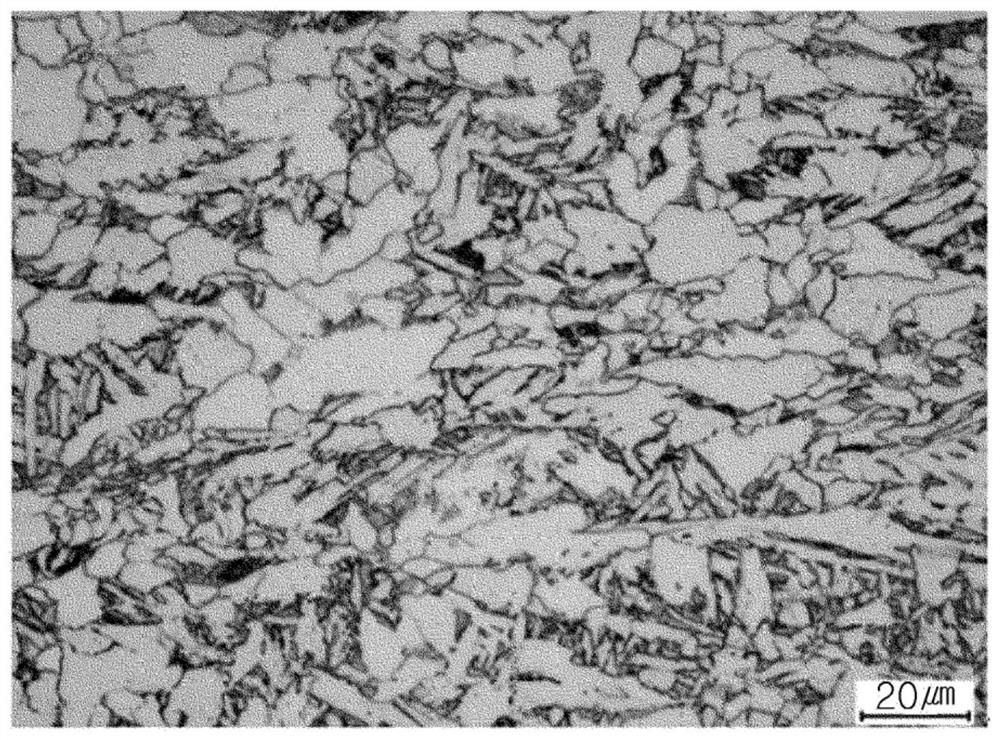

[0079] FIG. 1 is a photograph of the microstructure of Example 1 of the present invention. As can be seen from Figure 1, the

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com