Socket-type air duct connection fixture and air duct installation method

An installation method and a technology for connecting pipes, which are applied to sleeve/socket connections, pipes/pipe joints/fittings, building components, etc., can solve the problems of low installation efficiency, high cost, and long construction period of the air duct 10, and achieve reduction Small possibilities, high installation efficiency, and the effect of small installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

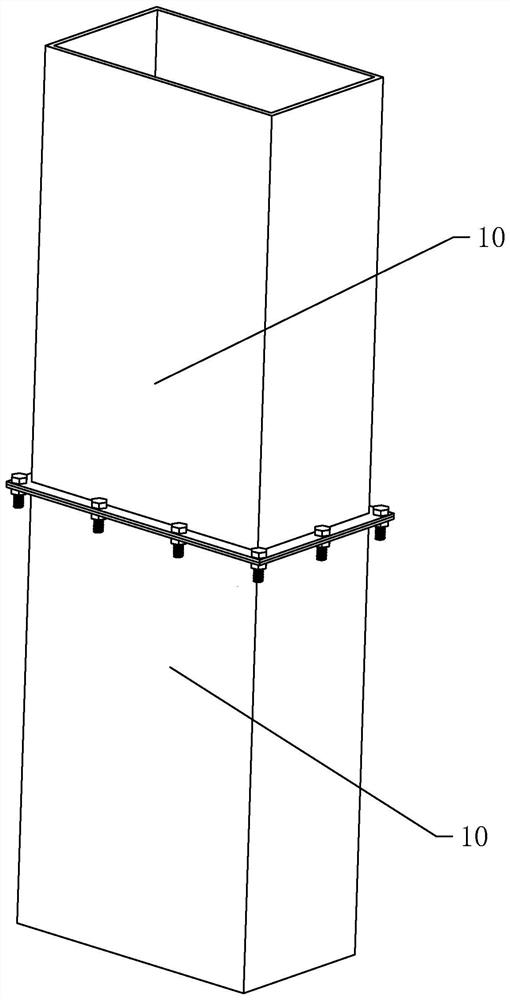

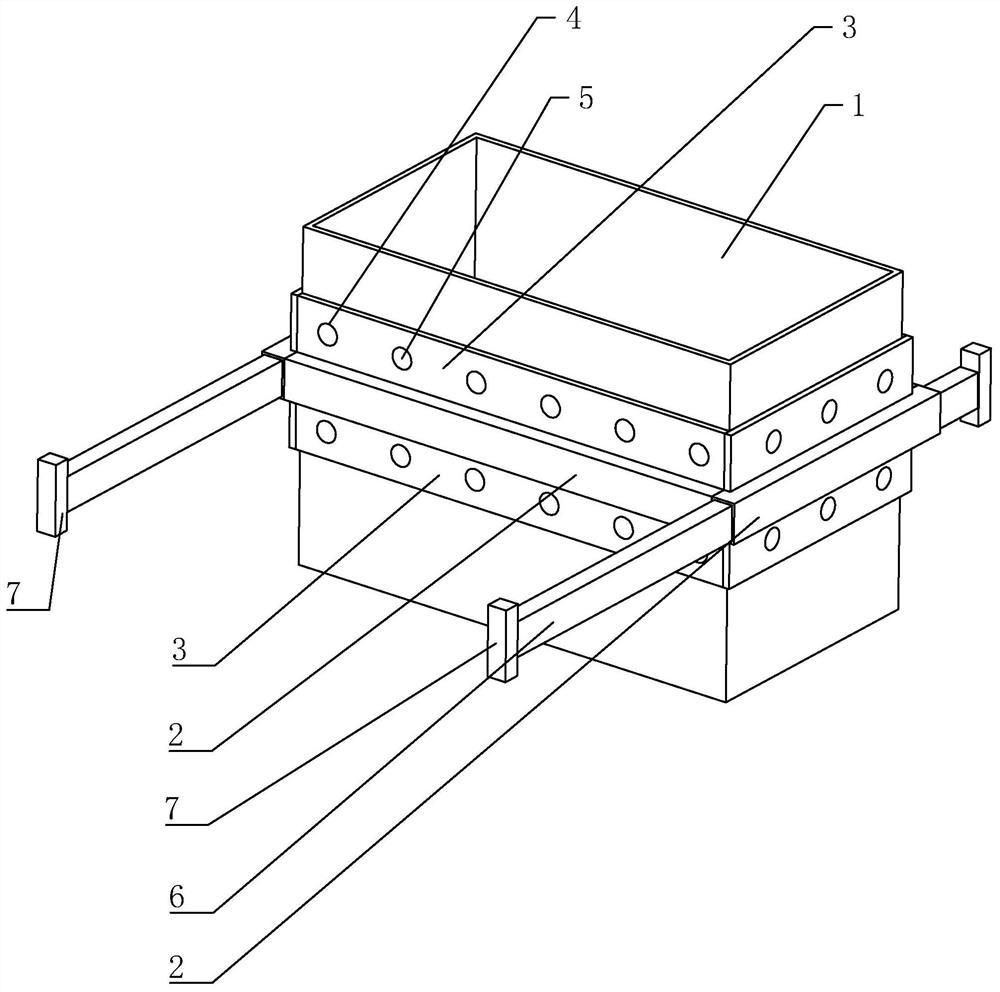

[0039]Example 1: Referencefigure 2 For a socket wind tube connection fixture disclosed in the present invention, a connecting member, a connecting member including a connecting tube 1 and a limiting strip 2, and the limit strip is set to four, four limit strips 2 respectively set On the four outer sidewalls of the connecting tube 1, the limit strip is disposed as a square tube, and the limit strip 2 is soldered between the connecting tube 1.

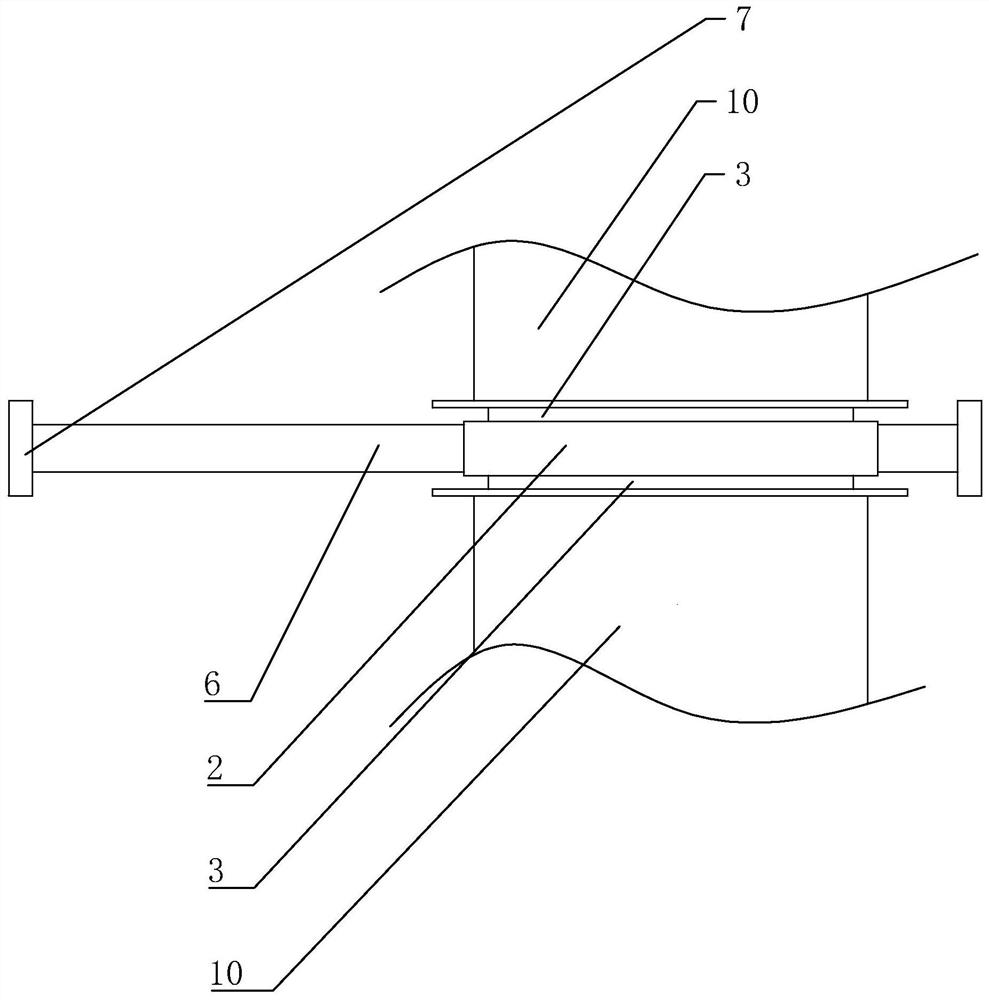

[0040]Referfigure 2 withimage 3 The two ends of the connecting tube 1 are in adjacent dumping 10, respectively, and the connecting tube 1 is an interference fit between the air tube 10 to connect the adjacent air tube 10, and adjacent the air tube 10 is in the limit strip 2. On both sides.

[0041]Referfigure 2 withimage 3 The outer side wall of the connecting pipe 1 is also connected to the friction strip 3, the friction strip 3 is the rubber strip, and the outer side wall of the connecting pipe 1 is welded to the raised column 5, the friction stri...

Embodiment 2

[0044]Example 2: An air tube mounting method using the above-described inserted duct connection fixture is disclosed in the present invention, which includes the following steps:

[0045]S1: Fixed the reinforcing bar on the connection block 11, embedding the reinforcement in opposing two-watery wall 9, and inserts the limit block 7 on both ends of the square steel 6 and the limit block 7 on both ends of the square steel 6, Pouring concrete towards the T-shaped groove 8;

[0046]S2: Inserting a duct 10 into one end of the connecting tube 1, the rubber strip offs away from the inner side wall of the contact pipe 10, the rubber strip is compressed;

[0047]S3: Insert another air tube 10 on the other end of the connecting tube 1, the rubber strip deps from the inside of the contact pipe 1 to the inner side wall, the rubber strip is compressed.

[0048]The implementation principle of the present embodiment is that the steel bar is welded to the connecting block 11 before mounting the air tube 10, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com