Rewinding splitting machine and bobbin paper manufacturing process applying same

A technology of slitting machine and installation tube, applied in papermaking, papermaking machines, calenders, etc., can solve the problems of reducing paper rewinding efficiency, inconvenient winding, etc., to improve rewinding and slitting efficiency, and facilitate up and down movement. , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

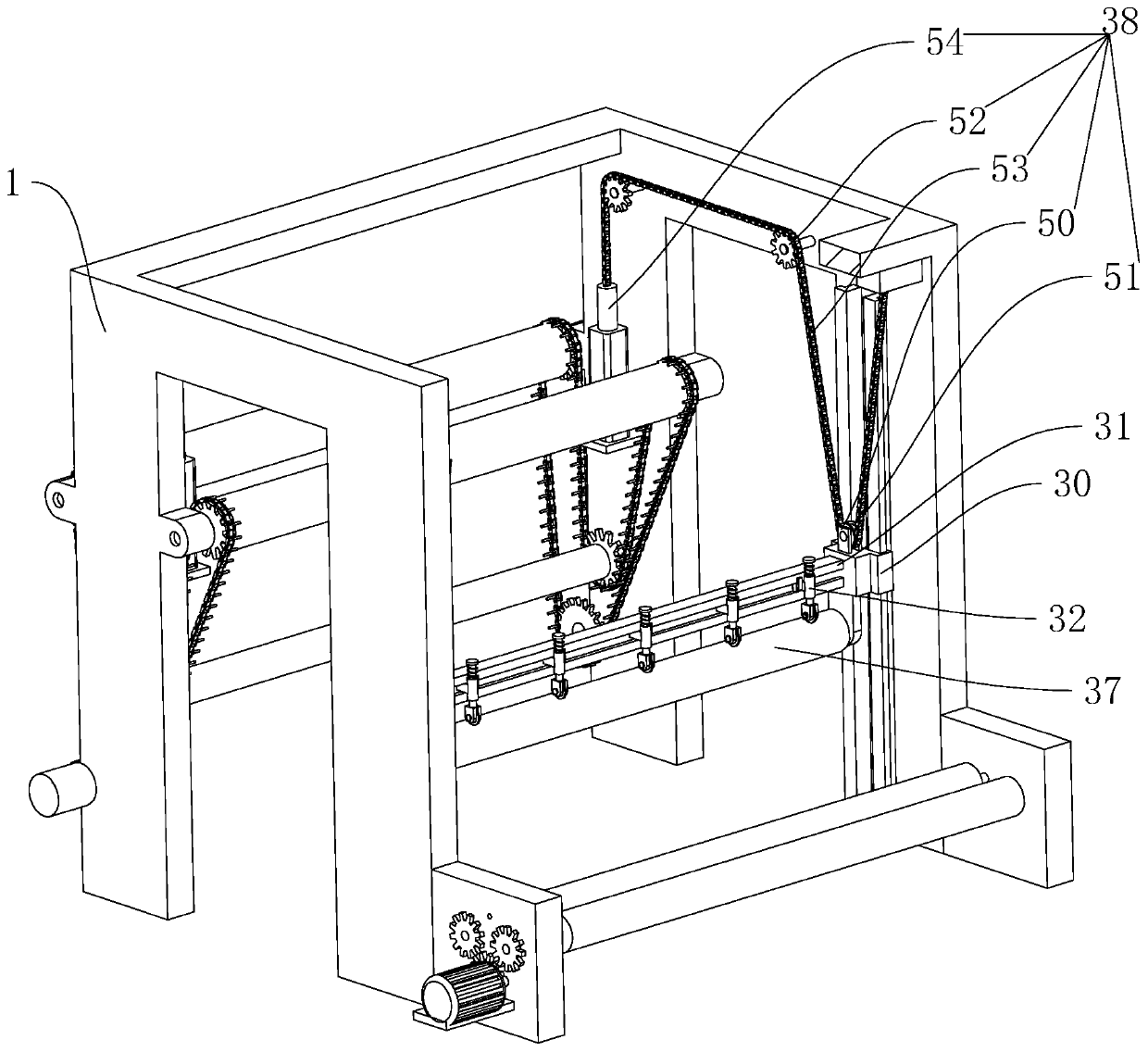

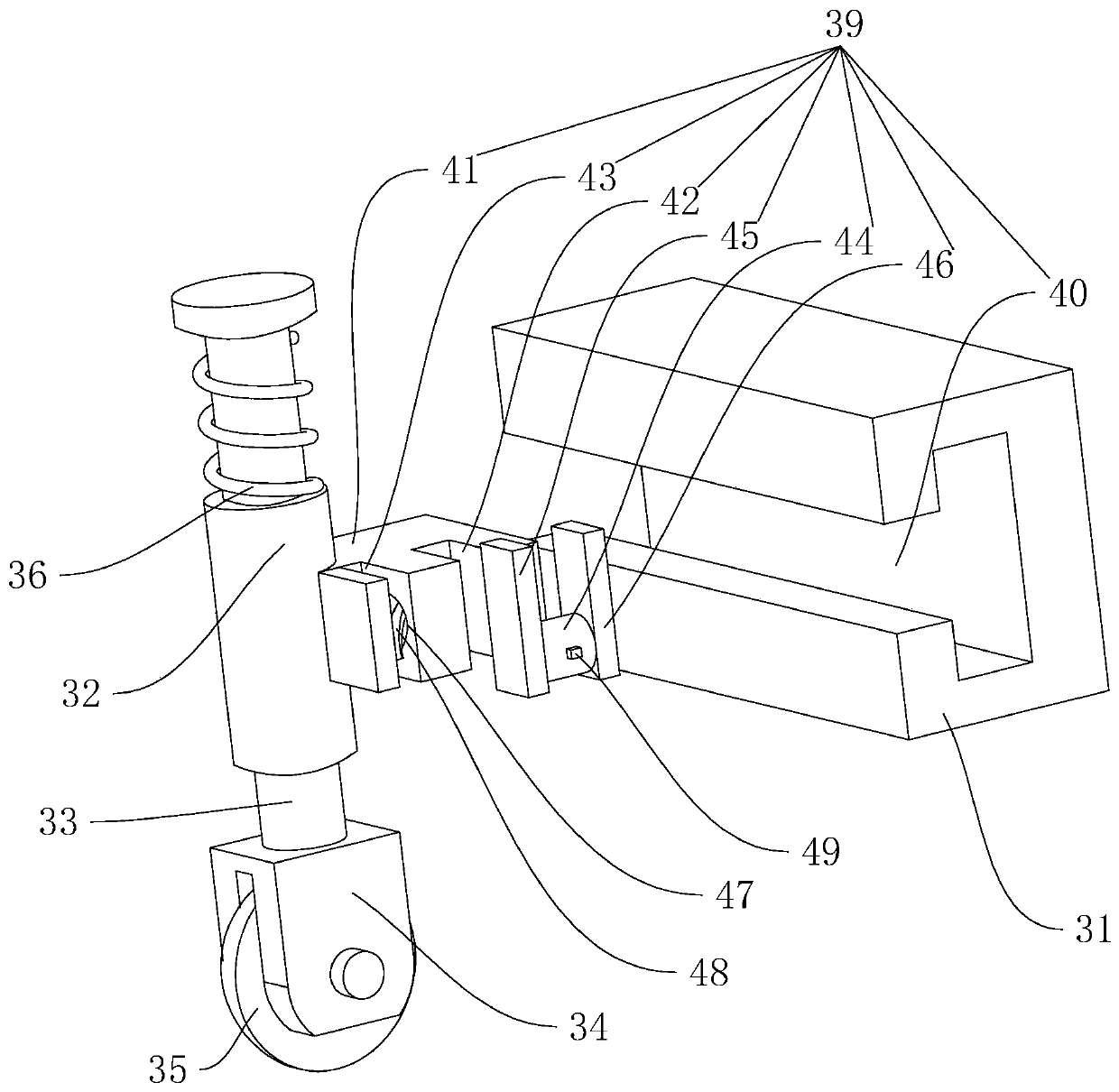

[0034] Embodiment one, such as figure 1 As shown, it is a rewinding and slitting machine disclosed by the present invention, which includes a support 1 , a feeding mechanism 2 is provided on one end of the support 1 , and a winding mechanism 3 is provided on the other end of the support 1 .

[0035] Such as figure 1 As shown, the feeding mechanism 2 includes a support frame 55 placed on the ground, an arc rod 56 fixedly connected to the support frame 55, a servo motor 57 fixedly connected to the support frame 55, and a servo motor 57 output shaft fixedly connected to the support frame 55. The driving gear 58 on the top is fixedly connected to the driving gear 59 on the outer wall of one end of the paper winding roller, and the driving gear 59 meshes with the driving gear 58.

[0036] Such as figure 1 As shown, the winding mechanism 3 includes two groups of winding rods 60 rotatably connected between the inner walls on both sides of the support 1, a winding gear 61 fixedly co...

Embodiment 2

[0045] Embodiment two, a bobbin paper manufacturing process, comprises the following steps:

[0046] Step 1, pulping, pulping made from bobbin paper waste pulp slag and waste cardboard;

[0047] Step 2: Dehydration forming in the wire section, the slurry is transported by the pump, and after dehydration on the Internet, paper sheets are formed;

[0048] Step 3: Pressing, the paper sheets are pressed together by the upper pressing roller and the lower pressing roller, so that the paper sheets are further dehydrated to obtain paper sheets;

[0049] Step 4, drying, the paper sheet enters the drying device to obtain cardboard;

[0050] Step 5, calendering, the cardboard enters the calender, and the cardboard is obtained after calendering;

[0051] Step 6. Roll paper and cardboard into the paper winding machine, roll into a cylindrical shape through the paper winding machine, and then pass through the rewinding and cutting machine to obtain the target product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com