Solar methane chemical-looping reforming reactor and using method thereof

A reforming reactor and solar methane technology, applied in chemical instruments and methods, solar collectors, solar thermal storage, etc., can solve imperfect concentrating systems, low solar energy utilization, and uneven temperature distribution in the reaction core area To achieve the effect of improving the utilization rate of solar energy, stable and controllable reaction, and ensuring the uniformity of temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

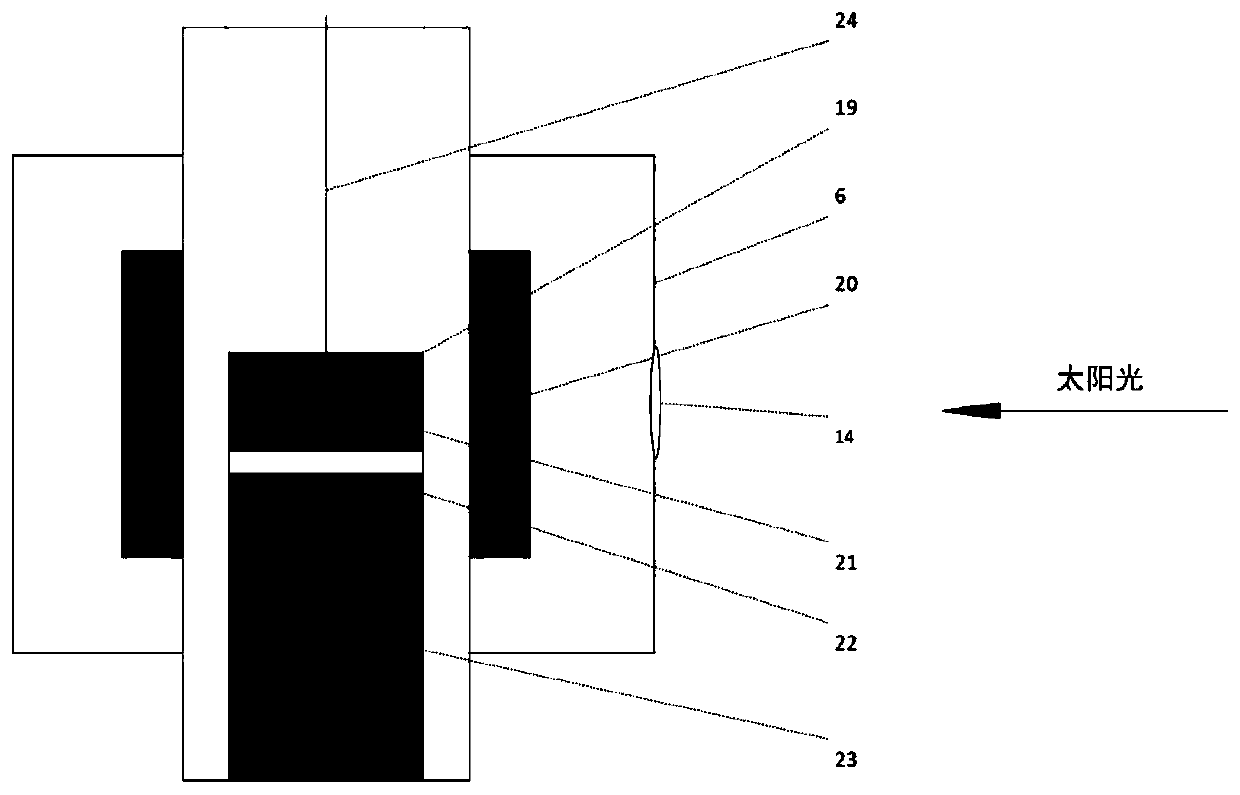

[0042] The principle, specific structure and best implementation mode of the present invention will be further described below in conjunction with the accompanying drawings.

[0043] see figure 1 , The solar methane chemical chain reforming reactor (illustrated by taking dry reforming as an example) of the present invention includes a feed area, a reaction area and a product collection area. Wherein, the reaction feed zone includes a carbon dioxide gas cylinder 1, a methane gas cylinder 2 and an argon gas cylinder 25, the carbon dioxide gas cylinder 1 is connected to the reactor 13, and the pipeline between the carbon dioxide gas cylinder 1 and the reactor 13 is provided with a first A gas volume flow controller 3, a second gas volume flow controller 4 is provided on the pipeline between the methane cylinder 2 and the reactor 13, a third gas volume flow controller 4 is provided on the pipeline between the argon cylinder 25 and the reactor 13 Volume flow controller 26.

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com