A tube shell golden finger cutting device

A technology of cutting device and shell gold, which is applied in the field of optical communication, can solve the problems of poor consistency and low efficiency, and achieve the effects of improving flexibility, improving production efficiency, and high consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

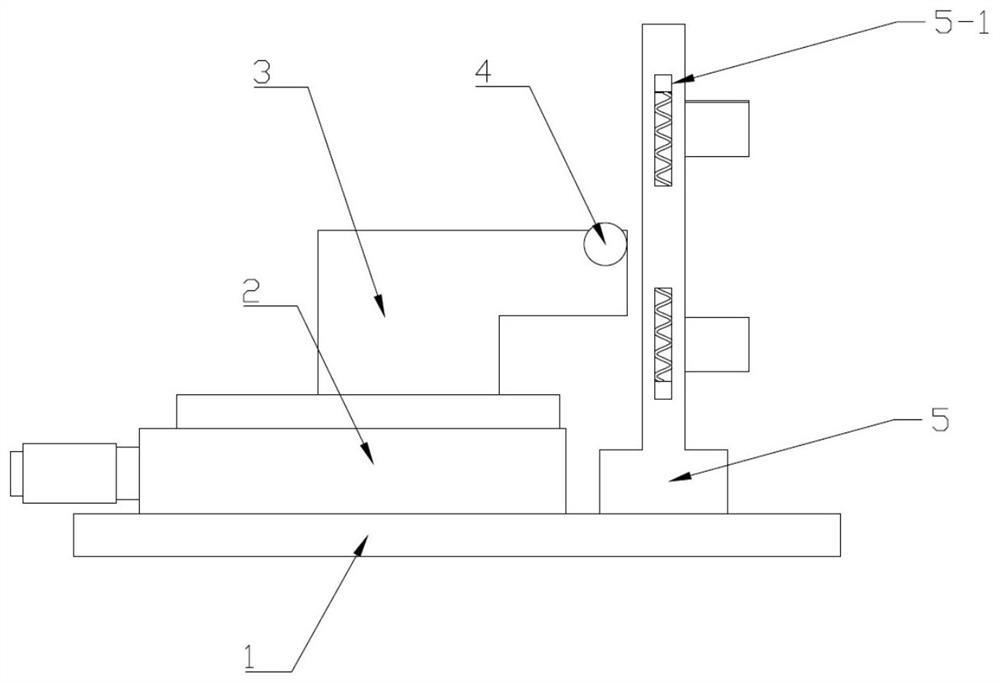

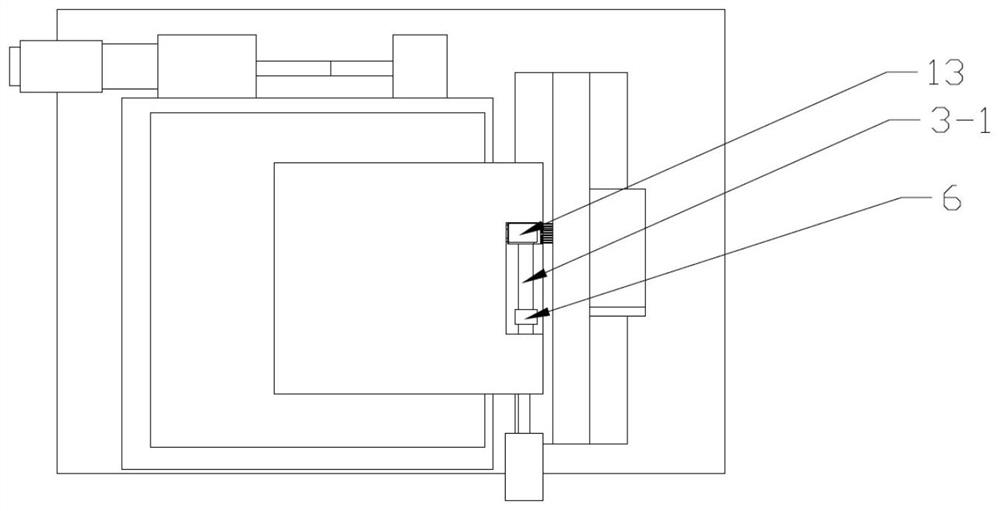

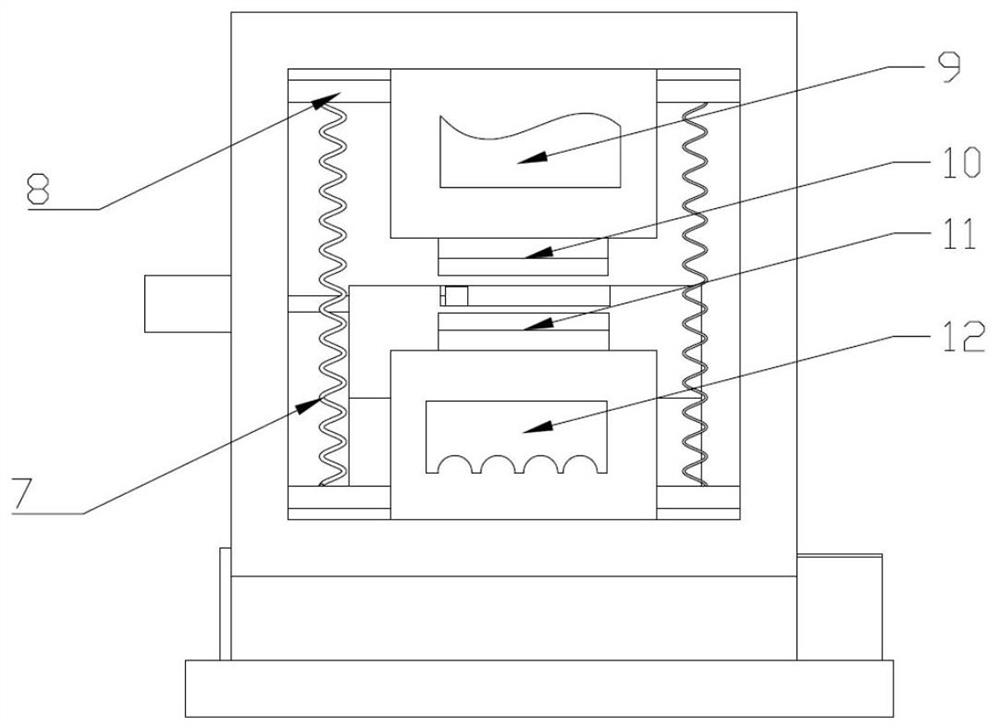

[0019] A kind of cutting device of tube shell golden finger of the present invention, its structure is as follows Figure 1-3 As shown, it includes fixed base 1, X-axis manual displacement fine-tuning platform 2, clamp 3, twisting wire 4, bracket 5, locking block 6, return spring 7, slider 8, upper cutter handle 9, upper cutter 10, Lower cutter 11 and lower cutter handle 12.

[0020] For the specific use process, take the 9PIN BOX laser as an example: place the tube shell 13 to be processed in the notch at the end of the fixture 3, align the light window side of the tube shell 13 with the edge of the fixture 3, and align the golden finger towards the cutter , then rotate the screw 4 to fix the shell 13 through the locking block 6, adjust it to a suitable position through the X-axis manual displacement fine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com