An ecological cycle device for harmless treatment of biogas slurry and residue

A harmless treatment and ecological cycle technology, applied in waste treatment, solid waste removal, etc., can solve problems affecting the normal operation of treatment equipment, low separation efficiency, filter blockage, etc., to achieve ecological recycling and improve utilization efficiency and avoid filter clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

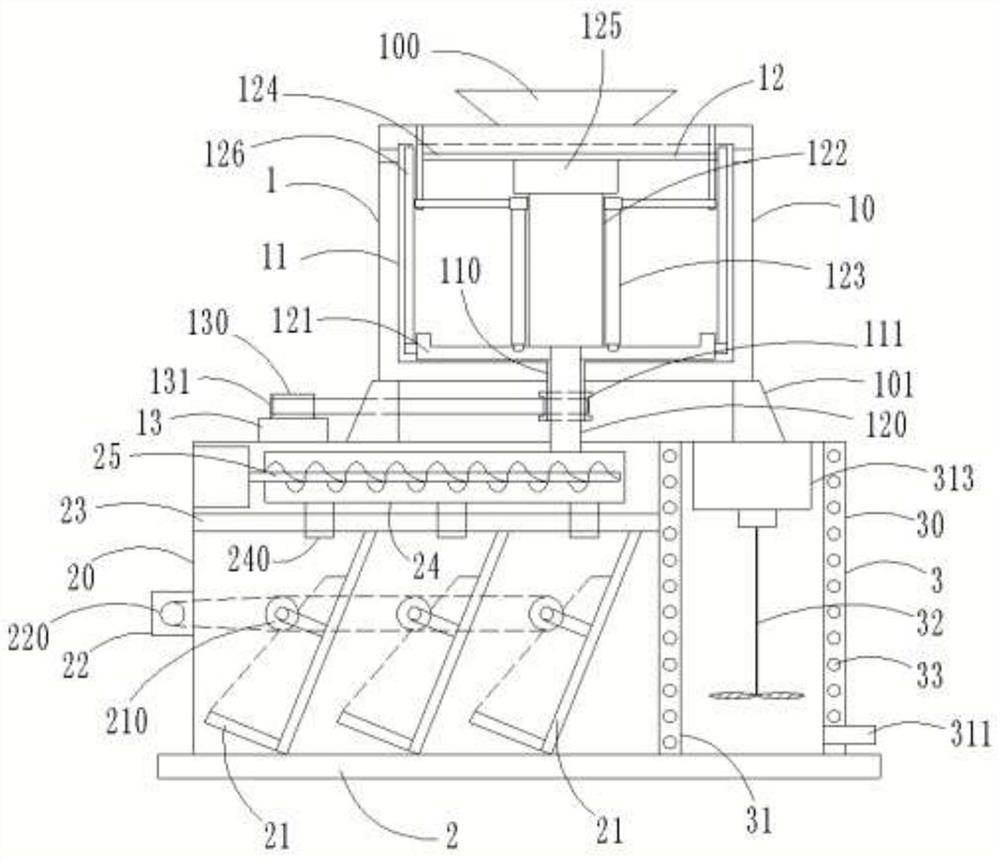

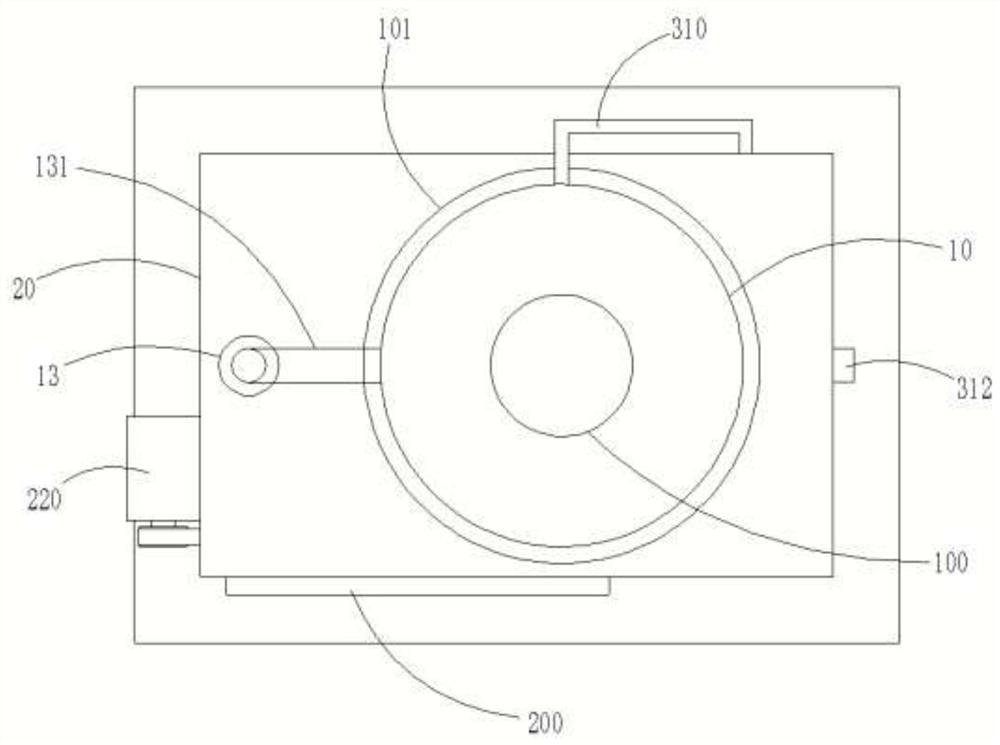

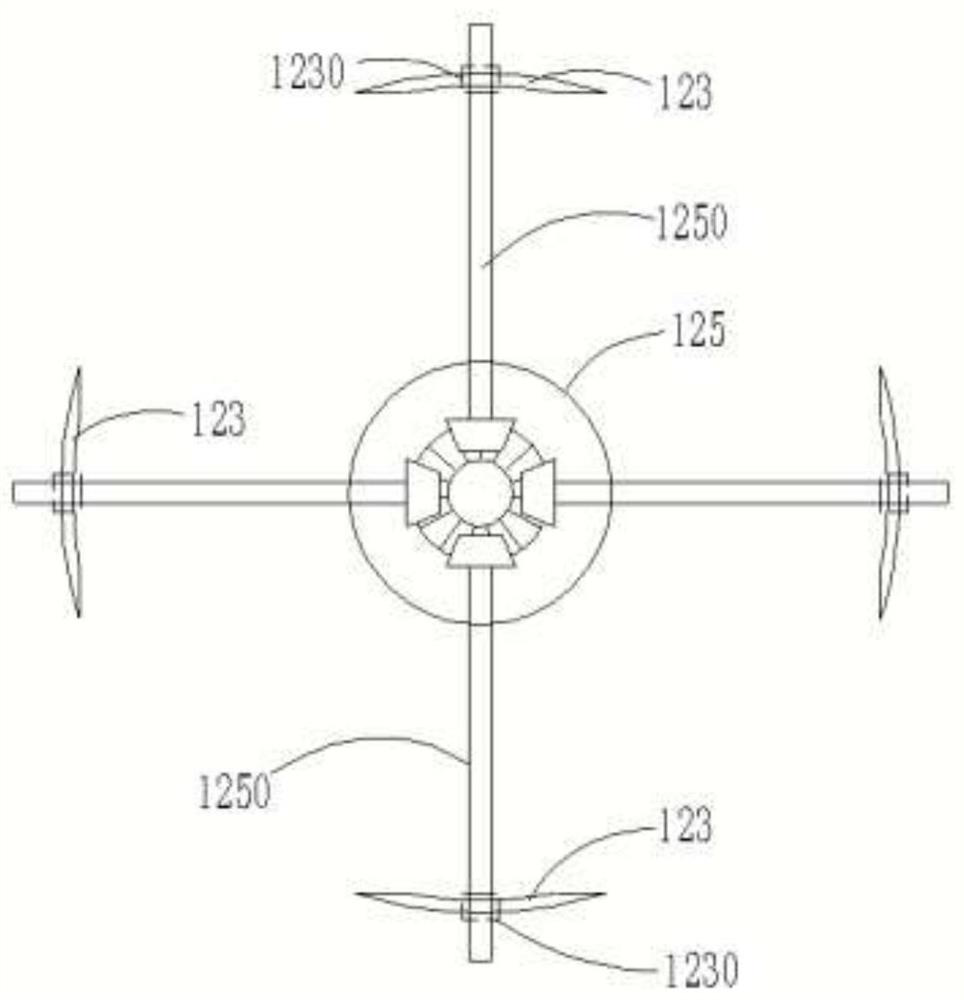

[0023] Example: such as figure 1 , 2, 3, 4, and 5 show an ecological cycle device for the harmless treatment of biogas slurry and residue, including a separation component 1, a biogas residue treatment component 2, a biogas slurry fermentation component 3 and a control box; the separation component 1 includes a separation box 10. Centrifugal cylinder 11, blanking member 12 and power motor 13, a feed hopper 100 is provided at the upper end of the separation box 10, a fixed seat 101 is provided at the lower end of the separation box 10, and the upper edge of the centrifugal cylinder 11 is engaged with the inner wall of the separation box 10. Then, the bottom of the centrifugal cylinder 11 is provided with a hollow shaft sleeve 110, the hollow shaft sleeve 110 runs through the separation box 10, the hollow shaft sleeve 110 is provided with a pulley 111, and the unloading member 12 is fixedly clamped on the inner top of the separation box 10, and the lower The lower end of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com