A kind of positive flotation magnesium removal inhibitor of phosphate rock and its application method

An inhibitor and positive flotation technology, which is applied in flotation, solid separation, etc., can solve the problems that are not conducive to large-scale production and use, long inhibitor preparation time, complex flotation process, etc., to achieve easy large-scale promotion, excellent Suppression effect, low separation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

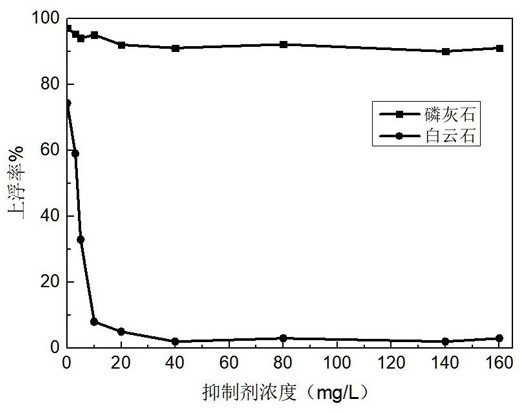

[0026] Take 2g of dolomite and apatite single minerals with a particle size of +38-74μm for flotation respectively, take 50mL of distilled water and add it to a 70mL hanging tank flotation machine, stir and adjust the slurry at a speed of 1300r / min to fully disperse the slurry .

[0027] Adjust the pH of the pulp to 9, according to figure 1 Add the medicament to the medicament system, stir for 3 minutes and 5 minutes after adding the medicament, the inhibitor is sodium alginate: cassia seed gum = 88:12, the concentrations are 0, 3, 5, 10, 20, 40, 80, 140, 160mg / L; the collector is sodium oleate (60.8mg / L), and after the stirring is completed, it will be aerated and floated to obtain foam products and tailings.

[0028] Filter, dry and weigh the foam product and tailings respectively, and calculate the floating rate, the result is as follows: figure 2 shown.

[0029] It can be seen that as the inhibitor concentration increases, the floating rate of apatite decreases slightl...

Embodiment 2

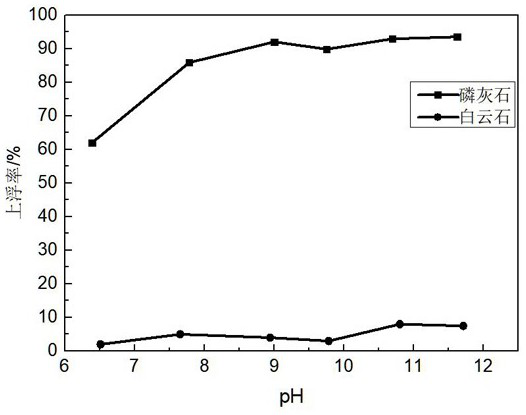

[0031] Take 2g of apatite and dolomite single minerals with a particle size of +38-74μm for flotation respectively, take 50mL of distilled water and add it to a 70mL hanging tank flotation machine, stir and adjust the slurry at a speed of 1300r / min to fully disperse the slurry.

[0032] The order of adding the medicaments is as follows: figure 1 As shown, sequentially add 20mg / L inhibitor (sodium alginate: cassia seed gum =90:10), and the collector is sodium oleate (60.8mg / L). After adding the agent, stir for 3 minutes and 5 minutes in turn. Adjust the pH of the ore slurry to 6.5, 7.8, 9.0, 9.8, 10.8, 11.8 before adding chemicals, and after the stirring is completed, aerate flotation to obtain foam products and tailings.

[0033] Filter, dry and weigh the foam product and tailings respectively, and calculate the floating rate, the result is as follows: image 3 shown.

[0034] It can be seen that in the pH range of 7.5-11.5, the floating rate of apatite is basically maintain...

Embodiment 3

[0036] Take 1.6g and 0.4g of +38-74μm apatite and dolomite single minerals and mix them uniformly according to the ratio of 8:2. Take 50mL of distilled water and add it to a 70mL hanging tank flotation machine, and stir at a speed of 1300r / min Adjust the slurry to allow the slurry to fully disperse.

[0037] The order of adding the medicaments is as follows: figure 1 As shown, the pH of the pulp is adjusted to 9.12 and 10.08 before adding chemicals, and then stirred for 3 minutes and 5 minutes after adding chemicals. (60.8mg / L). After the stirring is completed, air flotation is carried out to obtain foam products and tailings. Dry the foam product and tailings separately, weigh and test the P in the concentrate 5 o 2 , MgO content, calculate P in the concentrate 5 o 2 , The recovery rate of MgO. The result is as Figure 4 shown.

[0038] It can be seen from the examples that when the concentration of the inhibitor is 20 mg / L, the grade of MgO in the concentrate drops ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com