Normal-temperature automatic mixing device for high-viscosity liquid

A mixing device and high-viscosity technology, applied in the field of microfluidics, can solve the problems of reducing efficiency, increasing liquid diffusion time, etc., achieving the effect of flexible disassembly and reducing the cost of equipment use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

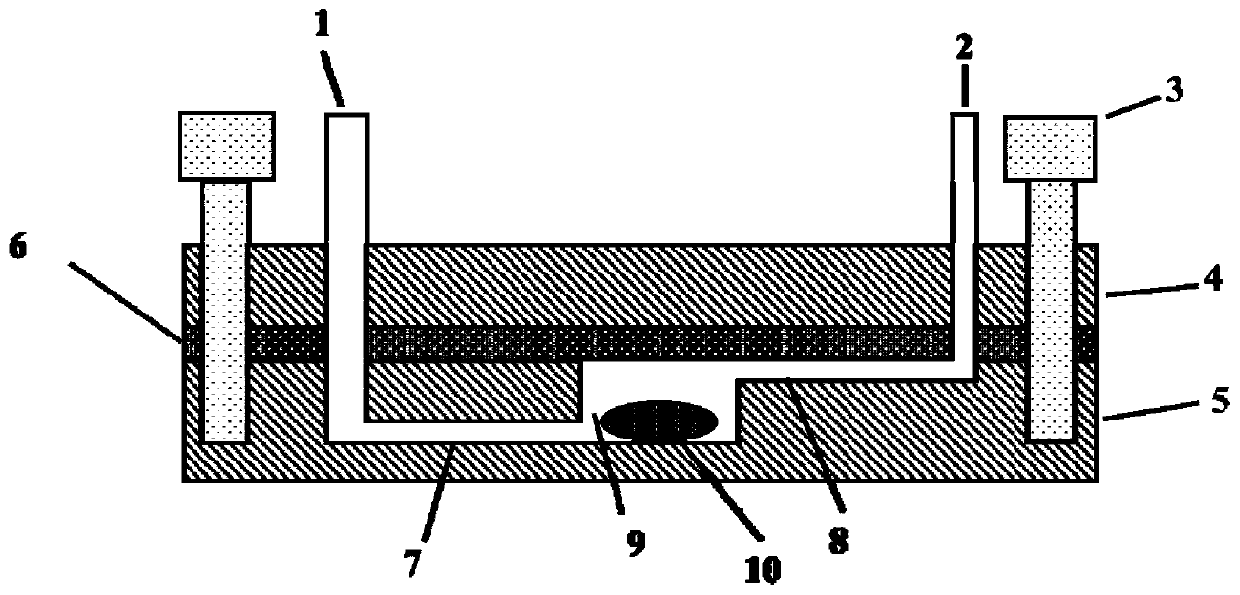

[0012] The high-viscosity liquid normal temperature automatic mixing device that the present invention proposes, its structure is as follows figure 1 As shown, it includes an upper cover plate 4, a lower cover plate 5, a sealing gasket 6 and a magnetic body 10. After the upper cover plate 4, the lower cover plate 5, and the sealing gasket 6 are stacked sequentially from top to bottom, they are fixed by fixing screws 3 fixed as a whole; the lower cover plate 5 is provided with a chamber 9, the magnetic body 10 is placed in the chamber 9, and the bottom of the chamber 9 is connected to the inlet on the upper cover plate 4 through the sample injection transverse channel 7. The sample channel 1 communicates with each other, and the upper part of the chamber 9 communicates with the sample output channel 2 on the upper cover plate 4 through the sample output transverse channel 8 .

[0013] Below in conjunction with accompanying drawing, introduce working principle and working proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com