Safety helmet and production method

A safety helmet and cap body technology, which is applied in the field of safety protection equipment, can solve problems such as single impact resistance, poor protection performance, and impact on safety performance, so as to improve the protection effect, excellent impact resistance and shock absorption performance, and ensure life safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

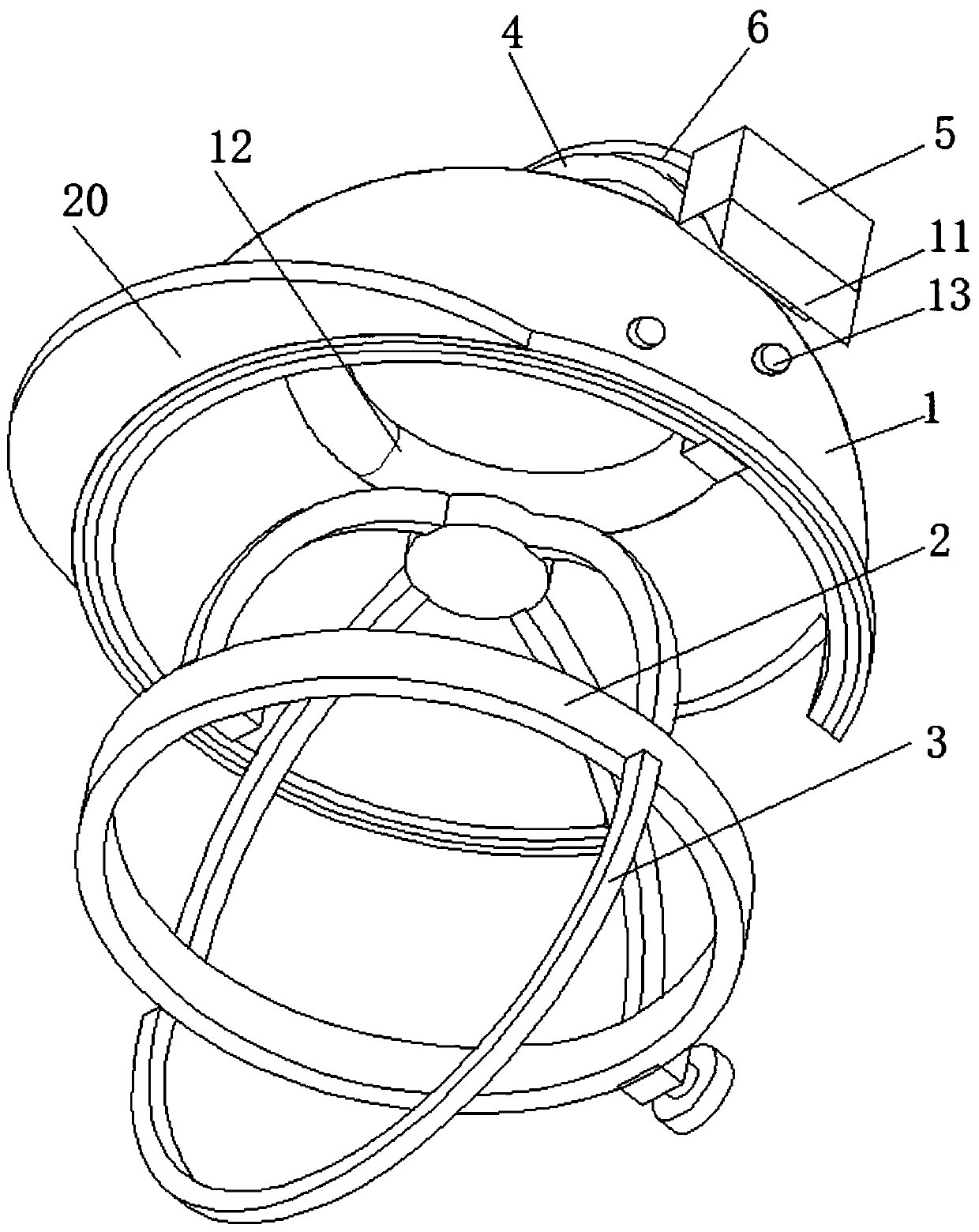

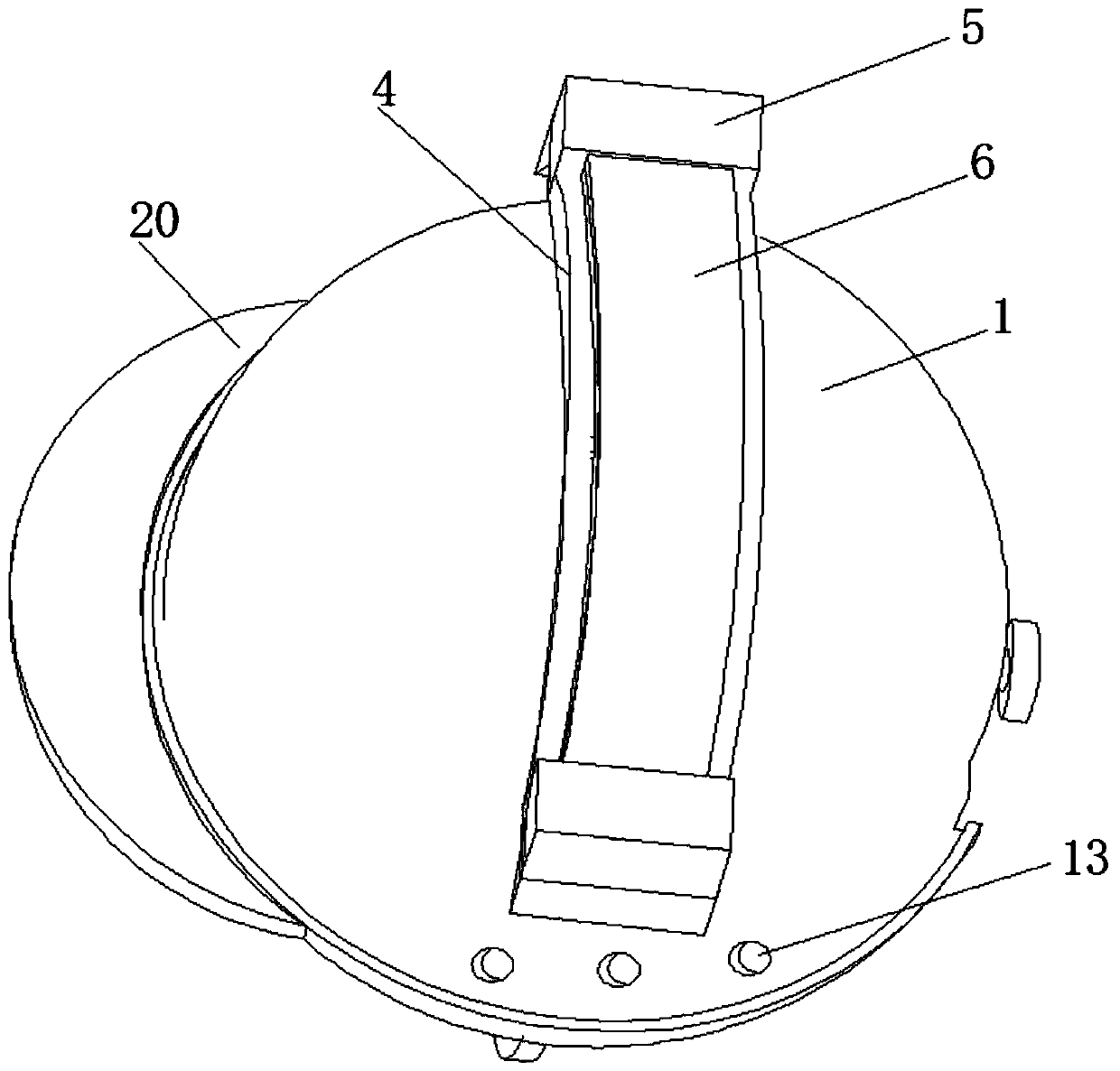

[0042] refer to figure 1 , figure 2 , image 3 and Figure 8 , a safety helmet, comprising a cap body 1, a cap liner 2 and a cap band 3, the top of the cap body 1 is connected with a horizontally placed arc-shaped reinforcing plate 4, and the two ends of the arc-shaped reinforcing plate 4 are movably connected with mounting blocks 5, An arc-shaped elastic piece 6 is connected between the mounting blocks 5, and the arc-shaped elastic piece 6 is located directly above the arc-shaped reinforcing plate 4. The two ends of the elastic sheet 6 squeeze the mounting block 5 to disperse the impact force, which solves the problem of single cushioning performance of the cap liner in the prior art and improves the protection effect.

Embodiment 2

[0044] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 6 and Figure 8, a safety helmet, which is basically the same as that of Embodiment 1, furthermore, a chute 7 is opened on the side of the arc-shaped reinforcing plate 4 away from the cap body 1, and two symmetrically distributed sliders are slidably connected in the chute 7 8. The opposite side of the slider 8 is movably connected with a support plate 9, and the side of the two support plates 9 away from the slider 8 is hinged through a hinge, and the hinge is connected to the middle of the arc-shaped elastic sheet 6, and the two sliders 8 are connected to each other. A buffer rubber plate 10 is connected between the far side and the groove wall of the chute 7. When an object hits the cap body 1 of the safety helmet, the arc-shaped elastic sheet 6 is squeezed, and the arc-shaped elastic sheet 6 transmits the pressure to the support plate 9. The support plate 9 drives the slider 8 to slide in the chute ...

Embodiment 3

[0046] refer to figure 1 , figure 2 , image 3 and Figure 8 , a safety helmet, which is basically the same as that of Embodiment 1, furthermore, the bottom of the installation block 5 is connected with a triangular rubber block 11, and the triangular rubber block 11 is offset against the cap body 1, when an object hits the cap body 1 of the safety helmet , Extrude the arc-shaped elastic sheet 6, and the two ends of the arc-shaped elastic sheet 6 extrude the mounting block 5, so that the triangular rubber block 11 is offset against the cap body 1, and the cushioning performance is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com