Polyimide resin and production method therefor, polyimide solution, and polyimide film and production method therefor

A technology of polyimide resin and polyimide film, which is applied in the fields of polyimide resin and its manufacture, polyimide solution, and polyimide film and its manufacture, can solve the problem of reduced transparency, The mechanical strength and toughness of the film are reduced, and it is not easy to be removed by water, so as to achieve the effect of excellent solubility, transparency and mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

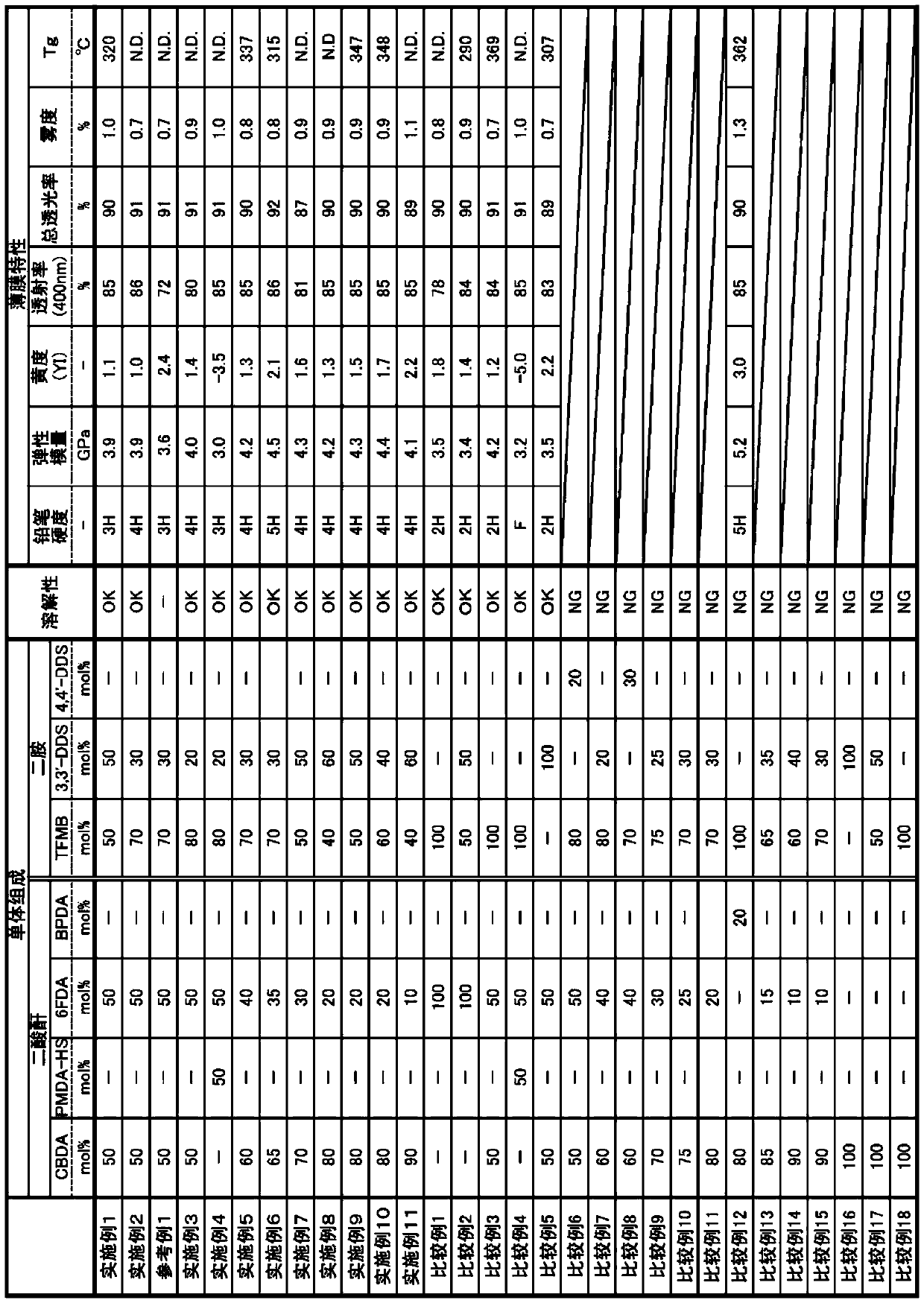

[0111] Hereinafter, the present invention will be described in more detail based on Examples and Comparative Examples. In addition, this invention is not limited to the following Example.

[0112] [Synthesis of polyamic acid]

[0113] 138 g of N,N- dimethylformamide (DMF) was put into the 500 mL separable flask, and it stirred under nitrogen atmosphere. Diamine and the dianhydride were injected|thrown-in at the ratio shown in Table 1 here, and it stirred and reacted for 5 hours in nitrogen atmosphere, and obtained the polyamic-acid solution of 18% of solid content concentration. The abbreviations of the monomers shown in Table 1 are as follows.

[0114] CBDA: 1,2,3,4-cyclobutanetetracarboxylic dianhydride

[0115] PMDA-HS: 1,2,4,5-cyclohexanetetracarboxylic dianhydride

[0116] 6FDA: 2,2-bis(3,4-dicarboxyphenyl)hexafluoropropane dianhydride

[0117] BPDA: 3,3’,4,4’-Biphenyltetracarboxylic dianhydride

[0118] TFMB: 2,2’-bis(trifluoromethyl)benzidine

[0119] 3,3’-DDS: 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com