Transport type blast hole blocking structure design method

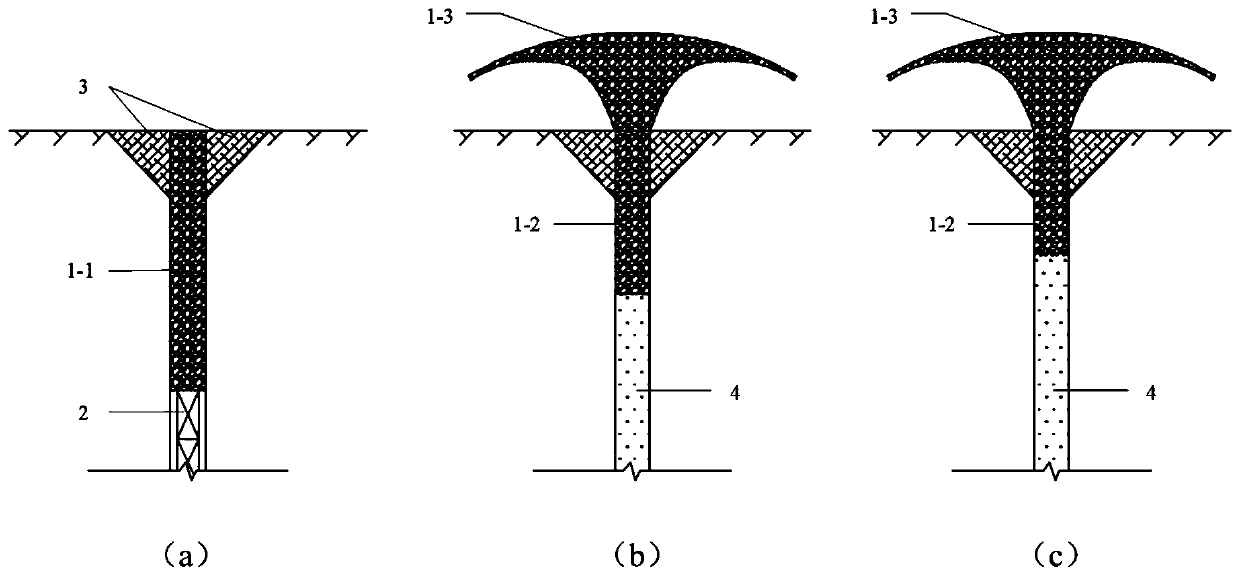

A technology for structural design and blasting holes, applied in blasting and other directions, can solve the problems of enhancing the blocking structure of blasting holes and the frictional resistance of the hole wall, the rate of large orifices, and the difficulty of blasting gas, so as to improve the energy utilization rate and reduce the hole size. The effect of increasing the blockage rate and increasing the range of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

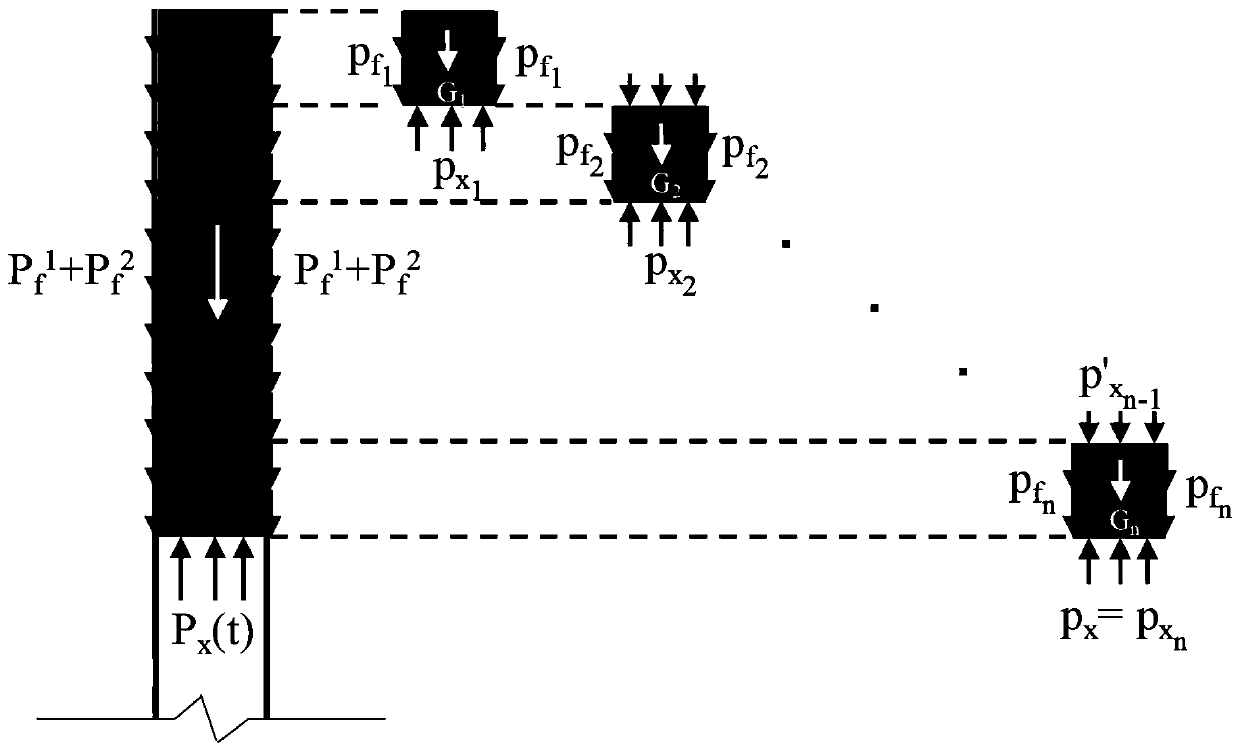

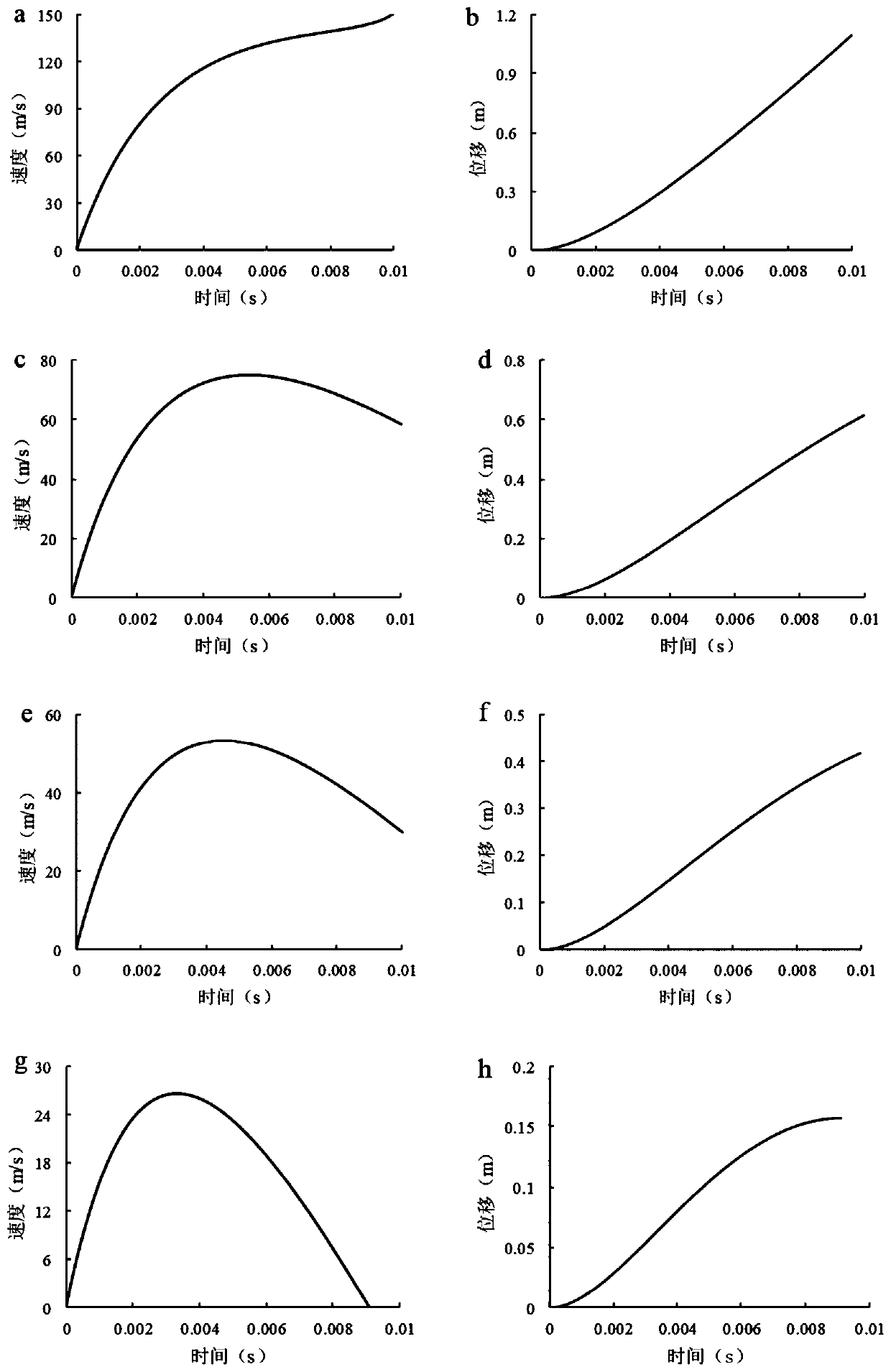

[0055] In an open-pit quarry, deep-hole bench blasting is used for stone mining. The explosive is No. 2 rock emulsion explosive. The diameter of the drug coil is 70mm, the distance between the blast holes is 3.7m, and the row distance is 2.5m. Drilling cuttings are used to plug the hole, and the plugging length is determined to be 1.6m to 3.0m according to the blasting parameters such as the hole diameter and the chassis resistance line according to the empirical formula in the "Blasting Manual". When the length of the blast is set to a large value, some blastholes are punched, the blasting gas escapes from the hole prematurely, and the blasting flying rocks are relatively serious; It cannot act on the rock mass around the blockage section, and there are many large rock masses at the orifice, with a high rate of large blocks. It is difficult to reasonably select the blocking length, so the design method proposed by the present invention is used to determine the blocking lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com