Structural system for flatly prefabricating and modularly transporting large-scale immersed tube tunnel tube section

A modular technology for immersed tube tunnels, applied in underwater structures, infrastructure engineering, barges/flat-bottomed boats, etc., can solve the problems of consuming land resources, restricting the use and promotion of immersed tube tunnels, and finding dry docking sites, etc. , to achieve the effect of saving cost and construction period, low water depth requirement of waterway, and flexible transportation mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better understand the purpose, structure and function of the present invention, the structural system of a flat prefabricated modular transport large-scale immersed tunnel section of the present invention will be further described in detail below in conjunction with the accompanying drawings.

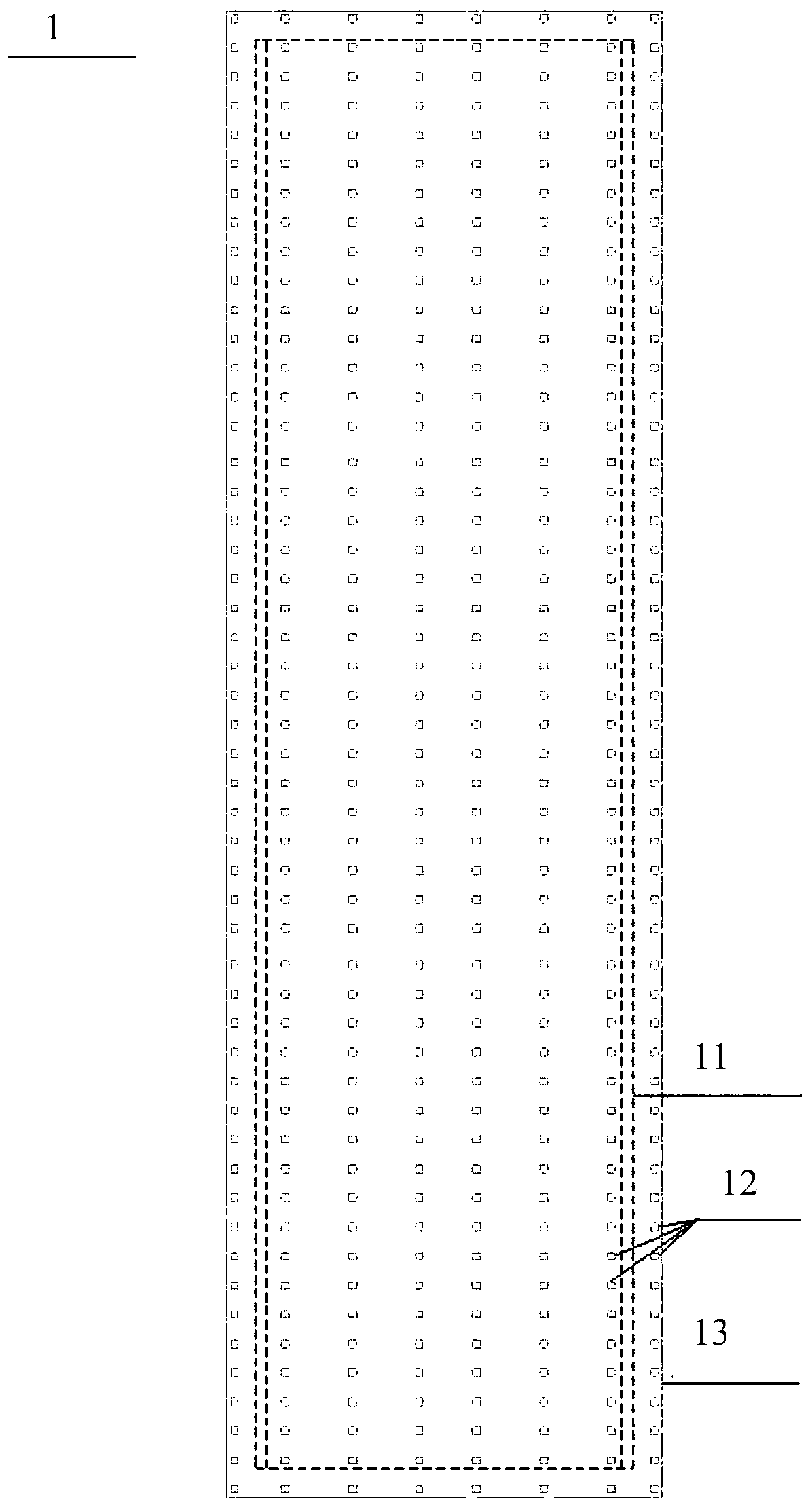

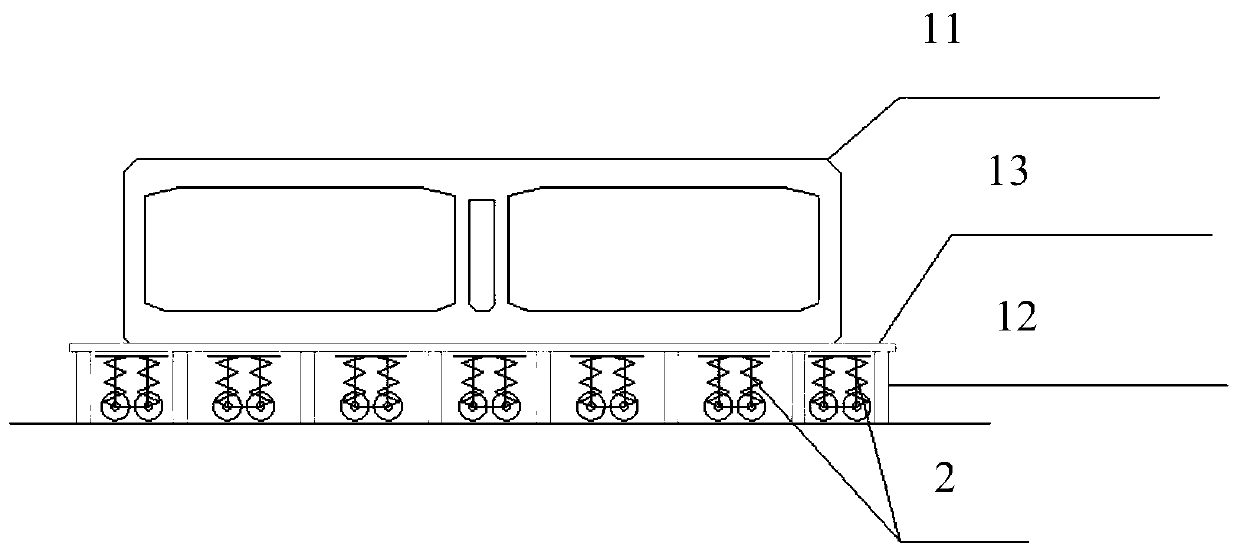

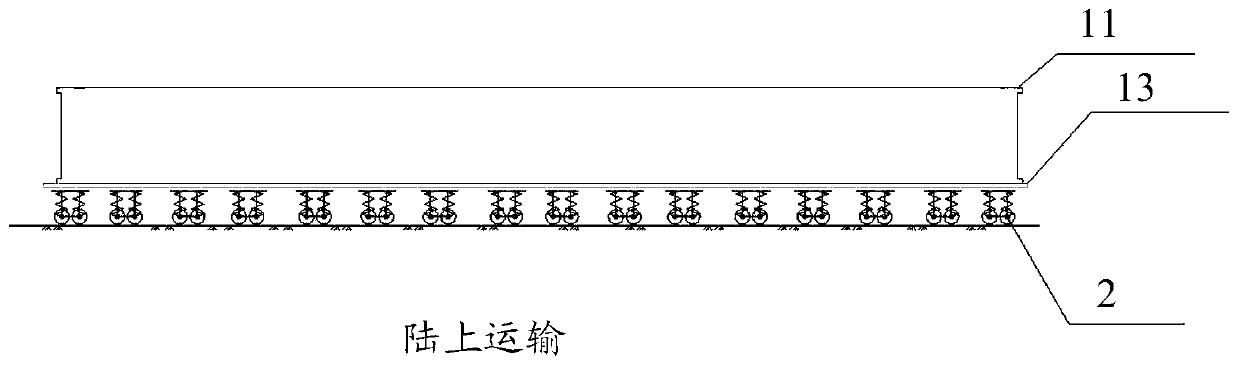

[0027] like Figure 1 to Figure 7 As shown, it is shown as a structural system for flat prefabricated modular transportation of large-scale immersed tunnel pipe sections of the present invention, including a land area prefabricated platform 1 for immersed pipe tunnel pipe sections, and a modular transportation platform 2 (multiple single modular transportation modules) and transport barges for oversized pipe sections with support platforms3. The present invention does not need to excavate a large temporary foundation pit beside the water area as the prefabricated site for the pipe section of the immersed tunnel, but pours the main structure of the pipe section of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com