Drive control system of collaborative robot

A technology of drive control and robotics, applied in the field of robotics, can solve problems such as incompleteness, achieve high security, enrich communication interfaces, and improve the effect of robot force control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

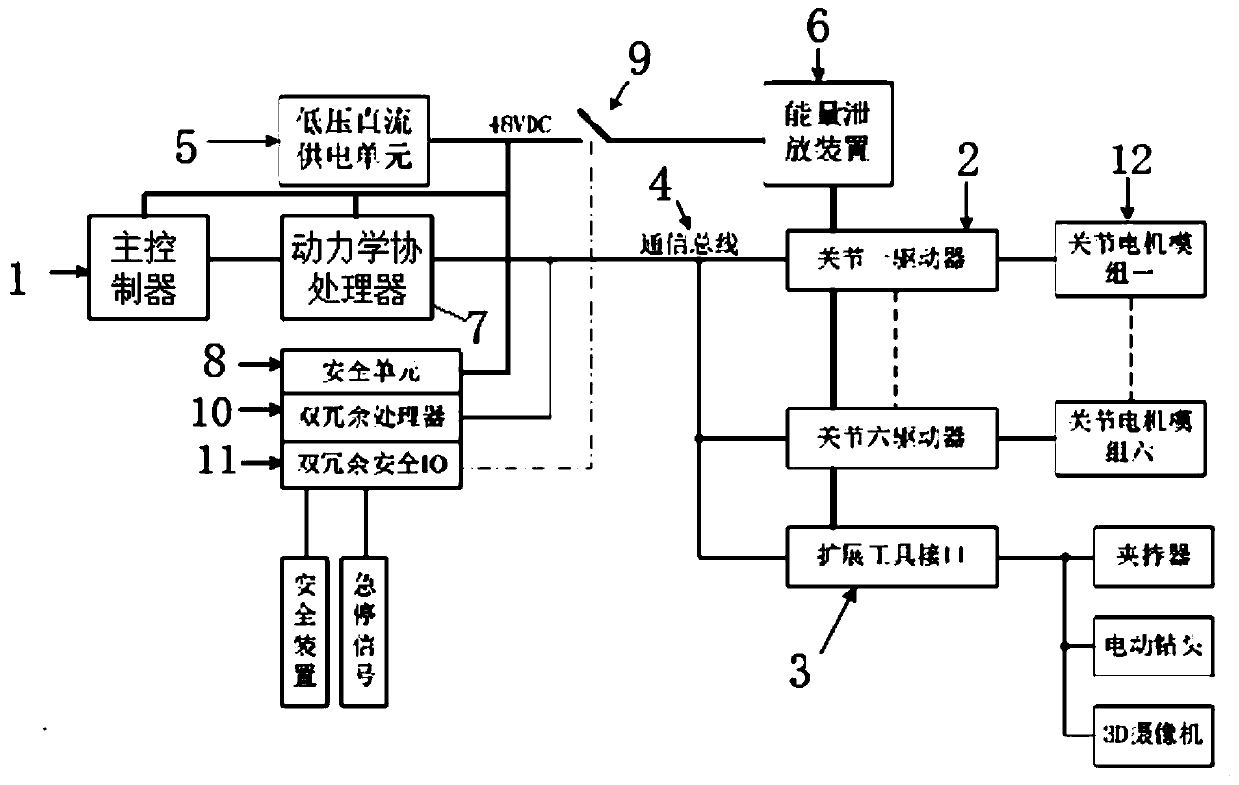

[0021] Such as figure 1 As shown, a collaborative robot drive control system includes a motion control loop, a low-voltage power supply loop and a safety control loop. The motion control loop includes a main controller 1, a dynamics coprocessor 7 and a joint motor drive controller, and the dynamics coprocessor The controller 7 is respectively connected with the main controller 1 and the joint motor drive controller, and the low-voltage power supply circuit is respectively connected with the motion control circuit and the safety control circuit.

[0022] The system integrates three loops, namely motion control loop, low-voltage power supply loop and safety control loop. The motion control loop includes a main controller 1, a dynamics coprocessor 7, and six independent robot joint drive units 2, namely joint 1 drive, joint 2 drive, joint 3 drive, joint 4 drive, joint 5 drive and joint 6 drive, Extension tool interface. The expansion tool interface 3 can be connected to auxilia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com