Efficient recyclable solid-liquid separation method and device for industrial wastewater

A technology for solid-liquid separation and industrial wastewater, applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve the problems of high operating cost, large amount of wastewater, low proportion of high-concentration suspended solids, etc., to improve efficiency, Effects that increase effectiveness and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

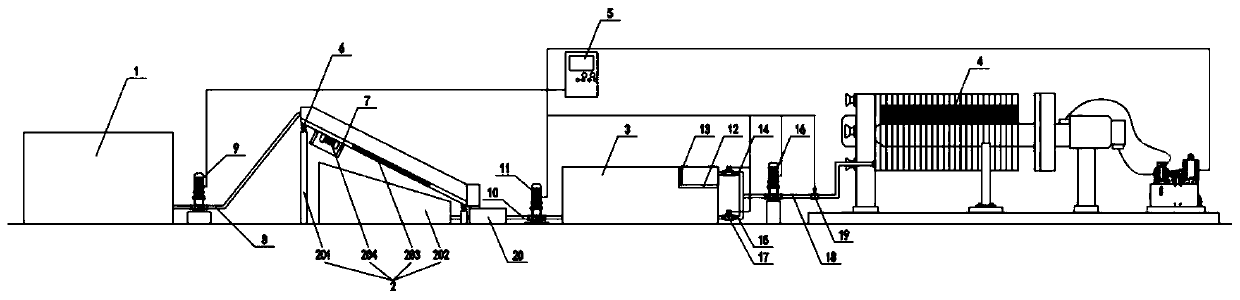

[0026] In order to facilitate the understanding of those skilled in the art, the structure of the present invention will be further described in detail with the embodiments in conjunction with the accompanying drawings:

[0027] refer to figure 1 , a high-efficiency recyclable solid-liquid separation device for industrial wastewater, comprising a wastewater collection tank 1, a vibrating screen 2, a sedimentation tank 3, a filter press device 4 and an electric controller 5 (the electric controller 5 in this embodiment) arranged in sequence Adopt programmable PLC coder), described vibrating screen 2 comprises frame 201 and the liquid sump 202 of fixing device below frame 201, and frame 201 top is obliquely installed with corresponding sieve plate 203 by buffer spring 6, described The top of the sieve plate 203 is fixedly connected with a corresponding vibration motor 204 downwards, the periphery of the vibration motor 204 is covered with a cover plate 7, and the sieve plate 203...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com