Silicate glass high-gain low-nonlinearity all-fiber ultrashort pulse amplifier and amplification method

A silicate glass, ultra-short pulse technology, applied in the laser field, can solve the problems of limited output pulse energy, poor stability, complex structure, etc., to avoid device damage, avoid insertion, and good beam quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

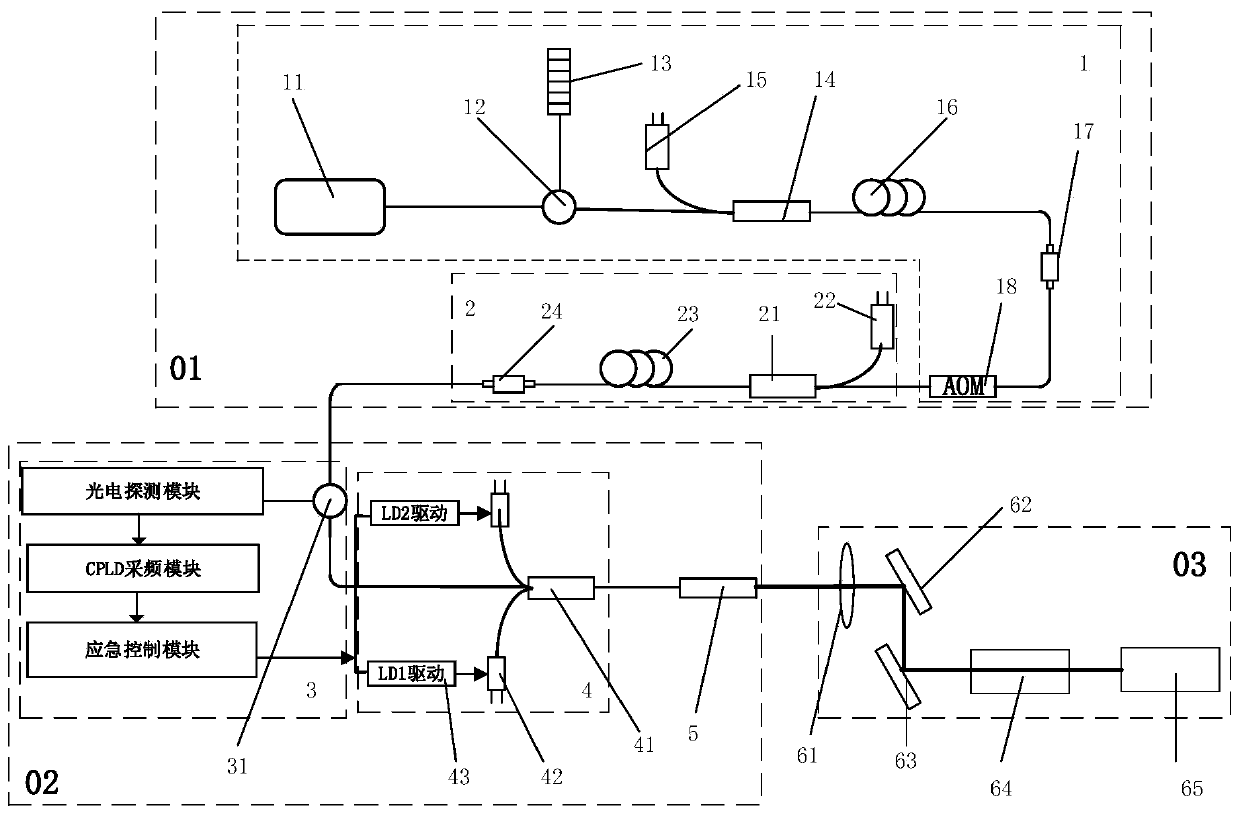

[0062] Such as figure 1 As shown, a silicate glass high-gain, low-nonlinear all-fiber ultrashort pulse amplifier includes a fiber pre-amplification system 01, an optical fiber main amplifier system 02, and a collimation isolation compression unit 03;

[0063] The optical fiber pre-amplification system 01 is used to realize the amplified output power of hundreds of milliwatts. The optical fiber pre-amplified system 01 includes a first-stage amplifying unit 1 and a second-stage amplifying unit 2 connected in sequence. The first-stage amplifying unit 1 is used to realize the amplified output power of milliwatts stage, repetition frequency 1MHz; this stage amplifying unit 1 includes a polarization maintaining mode-locking seed source 11, a first fiber circulator 12, a reflective chirped fiber grating 13, a first beam combin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Mode field diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com