Delay power strip

A delay circuit and socket technology, applied in electrical components, coupling devices, circuits, etc., can solve the problems of burning electrical equipment, large plug-in current, and high current, so as to avoid large current, use safely, and improve delay accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

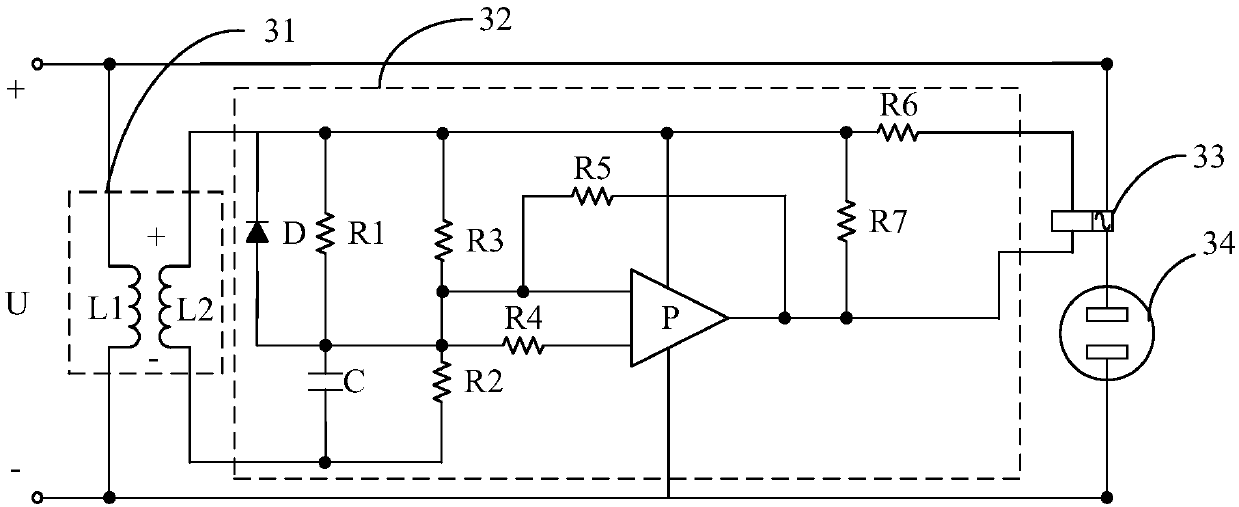

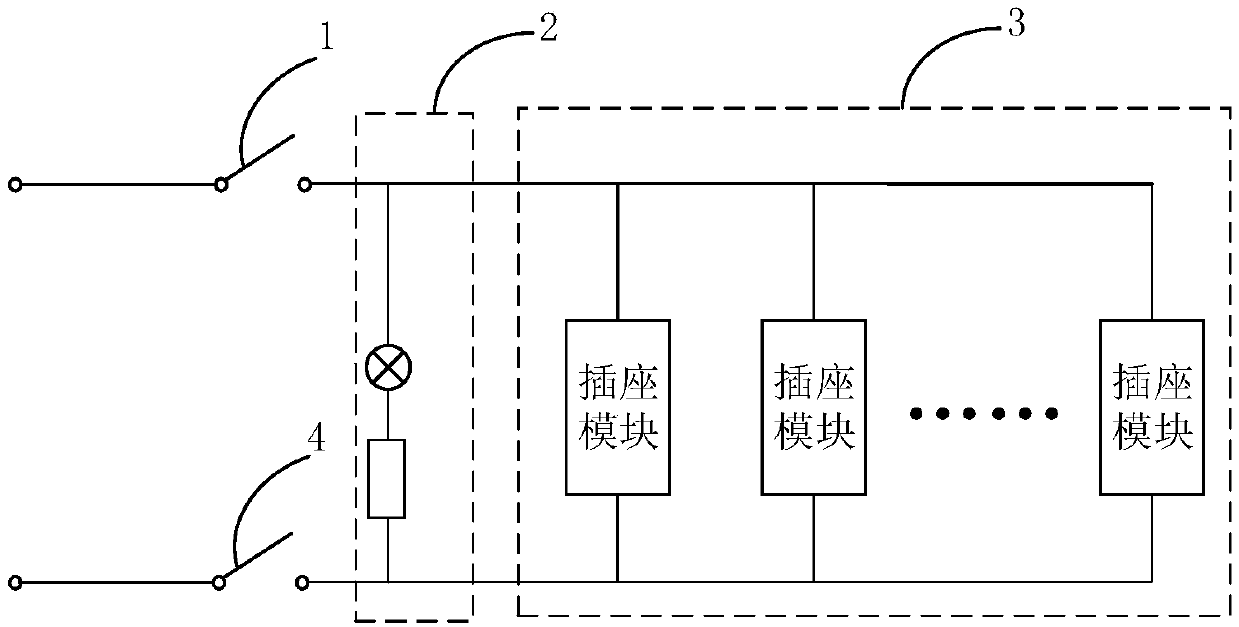

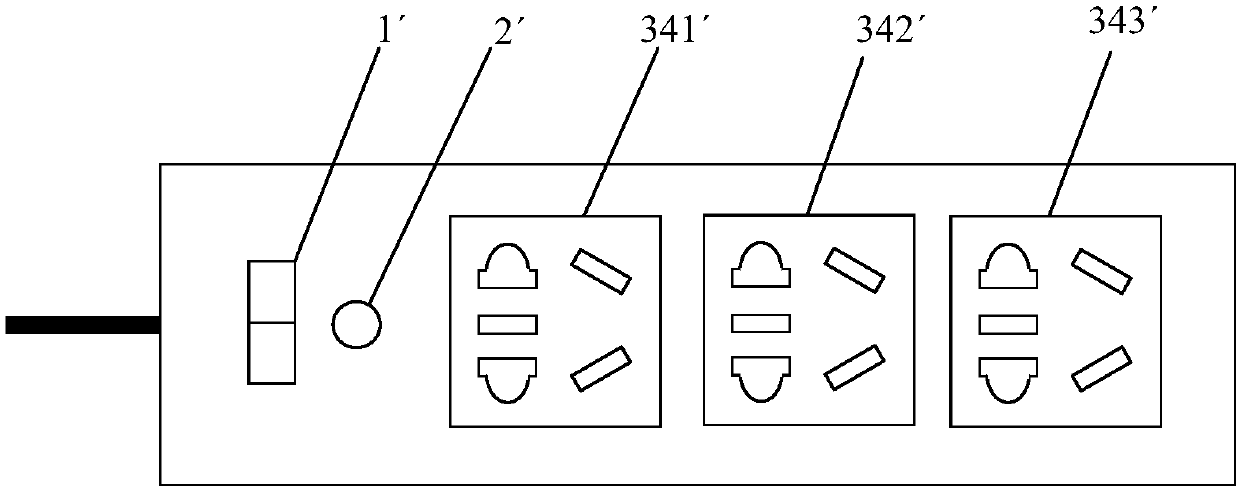

[0040] See figure 1 , figure 2 and image 3 . figure 1 It is a structural schematic diagram of a delayed insertion strip provided by the present invention; figure 2 It is a schematic structural diagram of a delay circuit of a delay plug-in provided by the present invention; image 3 It is a schematic diagram of the appearance of a delayed insertion strip provided by the present invention. Such as figure 1 As shown, a delayed plug-in strip includes: a first switch 1, an indicator light part 2, a socket part 3 and a second switch 4; wherein,

[0041] The indicator light part 2 and the socket part 3 are connected in parallel between the first switch 1 and the second switch 4;

[0042] The indicator light part 2 and the socket part 3 are connected to the high potential end through the first switch 1;

[0043] The indicator light part 2 and the socket part 3 are connected to the low potential end through the second switch 4;

[0044] The socket part 3 includes a plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com