Component carrier including PID and method for manufacturing component carrier

A component bearing and component technology, applied in semiconductor/solid-state device manufacturing, printed circuit manufacturing, final product manufacturing, etc., can solve problems such as increased manufacturing costs and complex manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

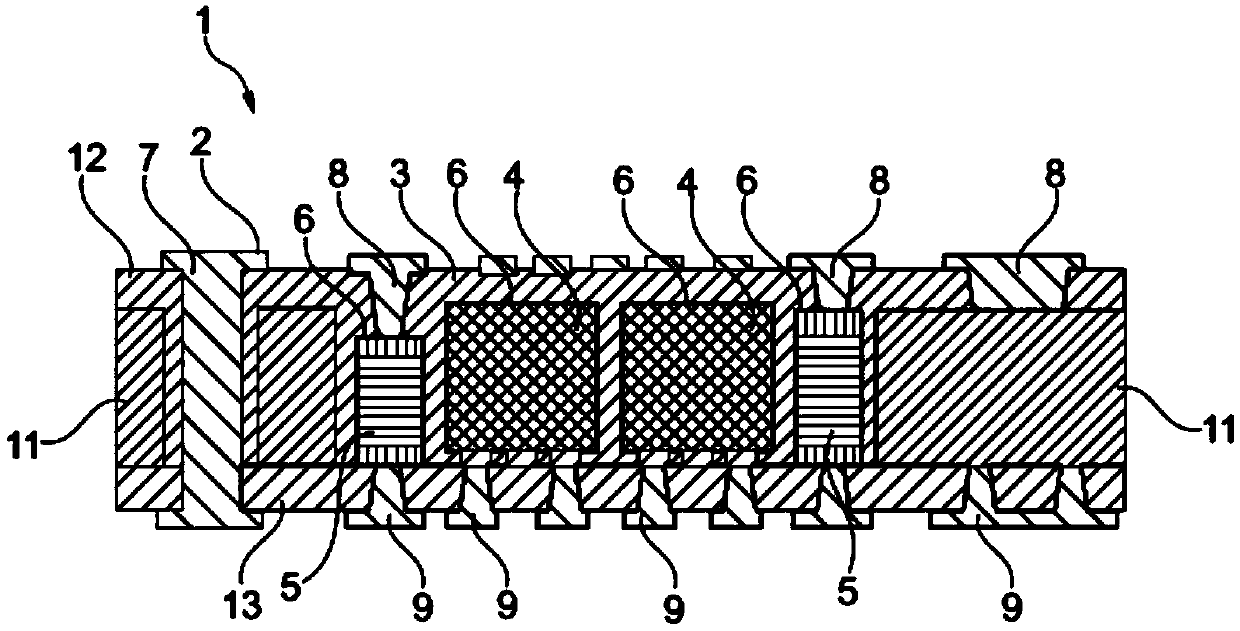

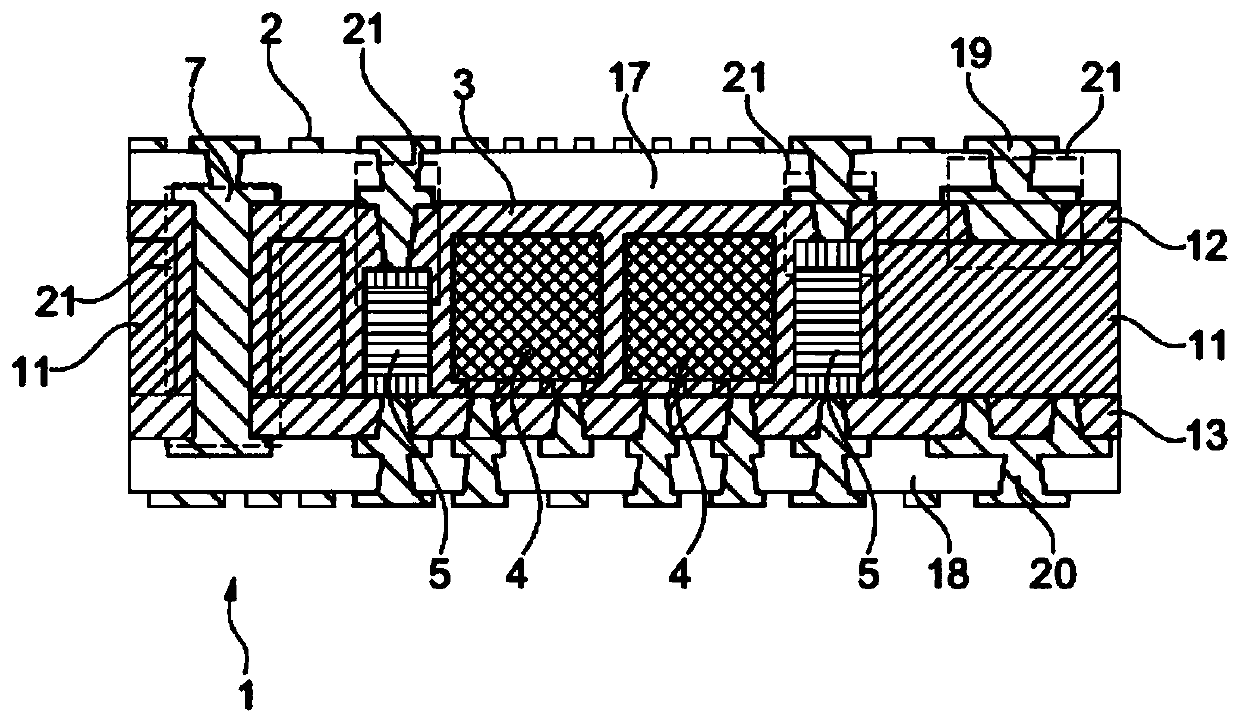

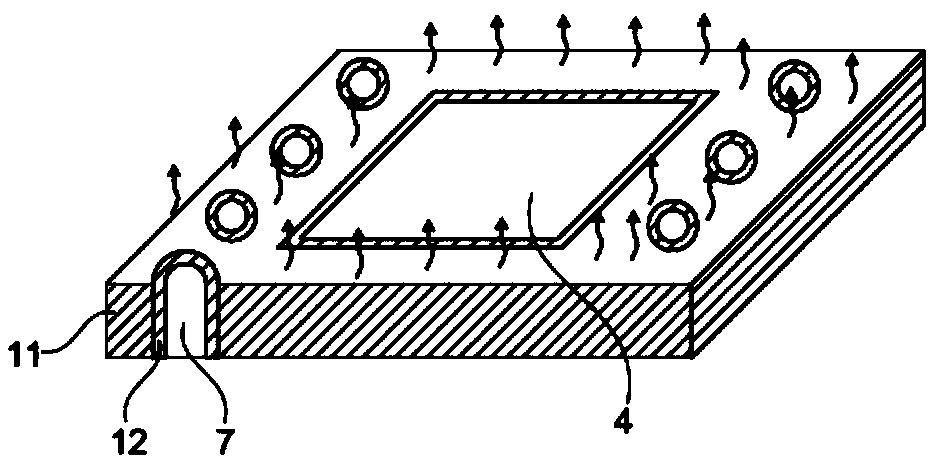

[0051] The illustrations in the figures are schematic. In different figures, similar or identical elements have the same reference signs.

[0052] Before describing the exemplary embodiments in more detail with reference to the accompanying drawings, some basic considerations upon which the exemplary embodiments of the present invention are developed will be summarized.

[0053] According to an exemplary embodiment, the nanocoating structure can be used in component carrier technology, in particular as a dry bonded structure. The adhesive layer that realizes this surface configuration can also be expressed as a gecko film. The adhesive effect of such surfaces can be based on van der Waals forces. Descriptively, multiple low-dimensional suction cups can be formed through such a concept. According to exemplary embodiments of the present invention, reliable substrates and / or structured materials are provided for embedded and / or surface mounted applications having specific adhe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com