Method for producing a piston

A technology for pistons and piston tops, applied to pistons, piston rings, additive manufacturing, etc., can solve problems such as low strength, increased weight, increased fuel consumption, etc., and achieve the effect of expanding the surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

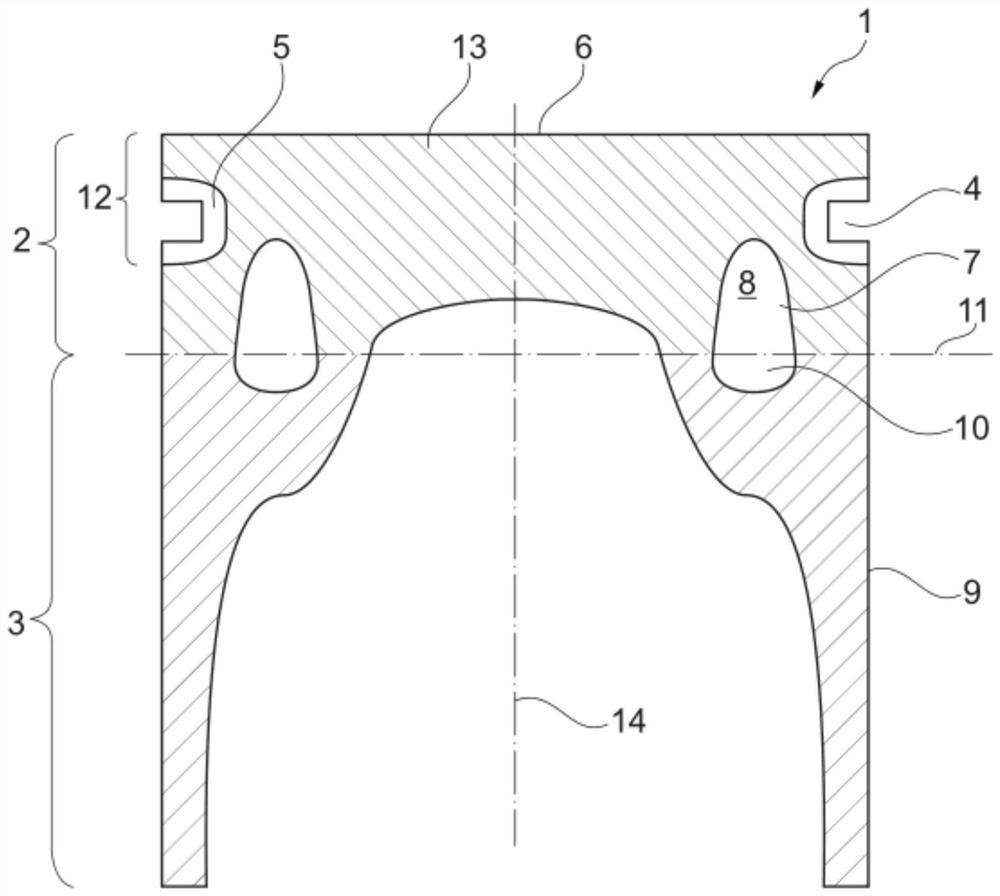

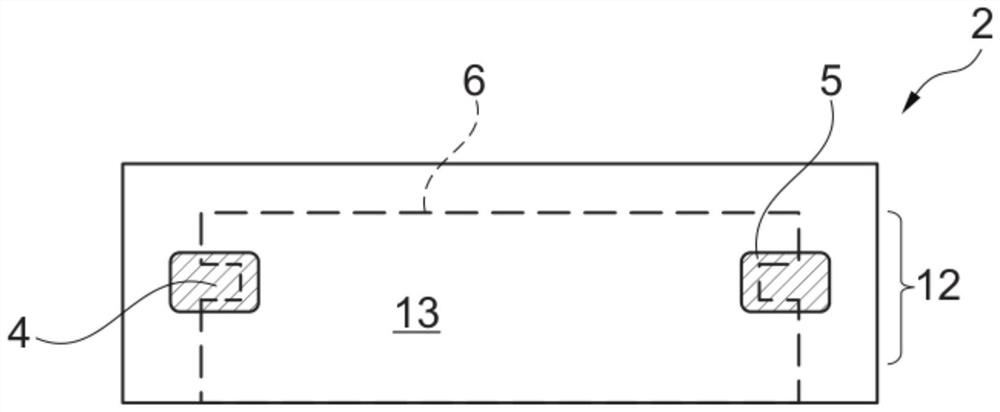

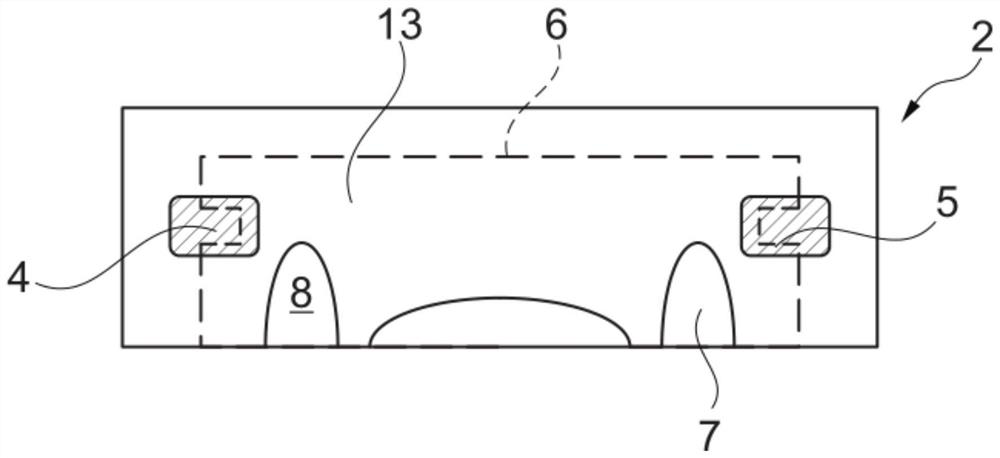

[0029] according to figure 1 , by the method according to the present invention (compare figure 2 and Figure 4 ) The piston 1 for an internal combustion engine (not shown) manufactured according to the invention has a piston upper part 2 and a piston lower part 3 . At least one annular groove 4 formed or reinforced by the annular support 5 is provided, for example, in the piston upper part 2 . Furthermore, the piston upper part 2 has a piston crown 6 facing the combustion chamber (not shown) and a part 7 of the cooling channel 8 . For the sake of brevity, according to figure 1 Piston crown 6 is depicted as a straight line, but it can of course also have a combustion chamber depression instead.

[0030] The piston lower part 3 generally has an at least partial piston skirt 9 for guiding the piston 1 in the cylinder and a piston pin hole boss (not specifically depicted) for receiving the piston The pin via which the piston 1 is connected to the connecting rod of the inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com