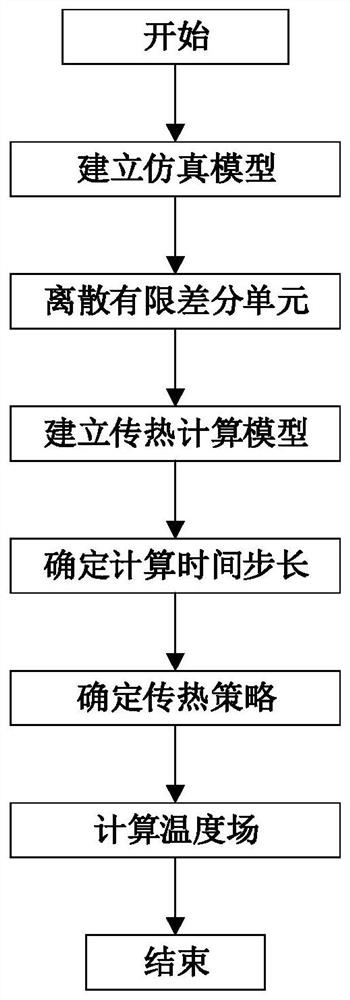

A Numerical Simulation Method of Temperature Field in SLM Forming Process

A technology of numerical simulation and forming process, applied in CAD numerical modeling, design optimization/simulation, calculation, etc., can solve the problems of limiting the development and application of numerical simulation of SLM forming process, insufficient calculation accuracy, etc., to reduce computer memory and storage. The effect of space, ensuring calculation accuracy, and accurate calculation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Consider developing a calculation software based on this method to realize the temperature field simulation function.

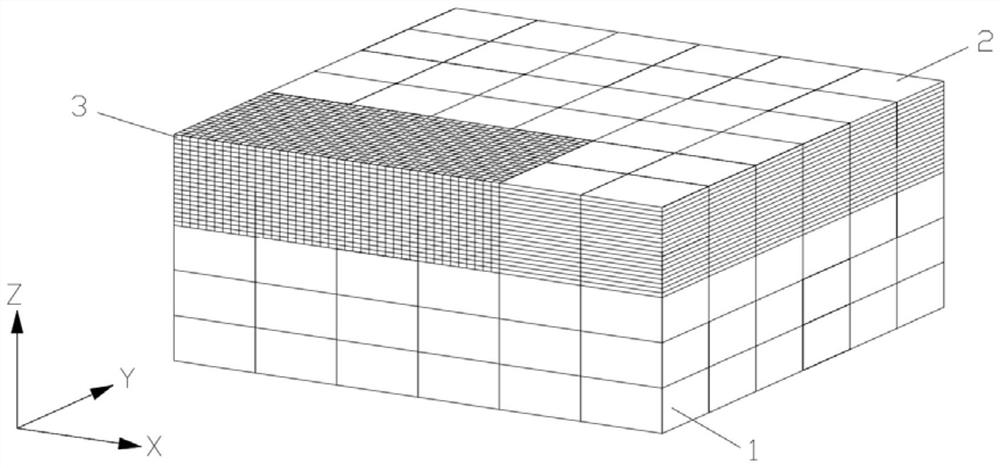

[0068] (1) Establish a substrate model with a size of 20mm*20mm*10mm, and a sample model with a size of 10mm*10mm*1.5mm. The substrate material is 316L stainless steel, and the forming powder is 316L stainless steel powder.

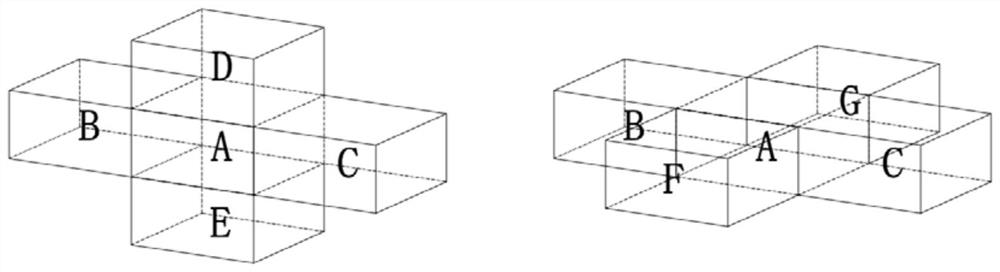

[0069](2) The substrate model and the sample model are according to the E of 1mm*1mm*0.5mm L The unit is discrete, and a total of 9200 E L Unit, 9200 E L Units contain the powder units formed during the SLM powder spreading process. Among them, the substrate always exists, and the prototype is gradually generated during the forming process. The sample layer E that is being formed L Unit and its lower layer E L 8,000 sheet-type Es with a size of 1mm*1mm*0.05mm are obtained by finely segmenting the unit M unit so that 4×2×2 E L Unit contains all E M The unit is refined and divided to obtain 16,000 Es with a size of 0.1mm*0.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com