A rca paper tape friction machine

A friction machine and paper tape technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of low accuracy of measurement results, rough classification methods, and inability to set the hardness and softness, and achieve a wide range of load adjustment and ensure Feasibility, safety improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those in the technical field to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

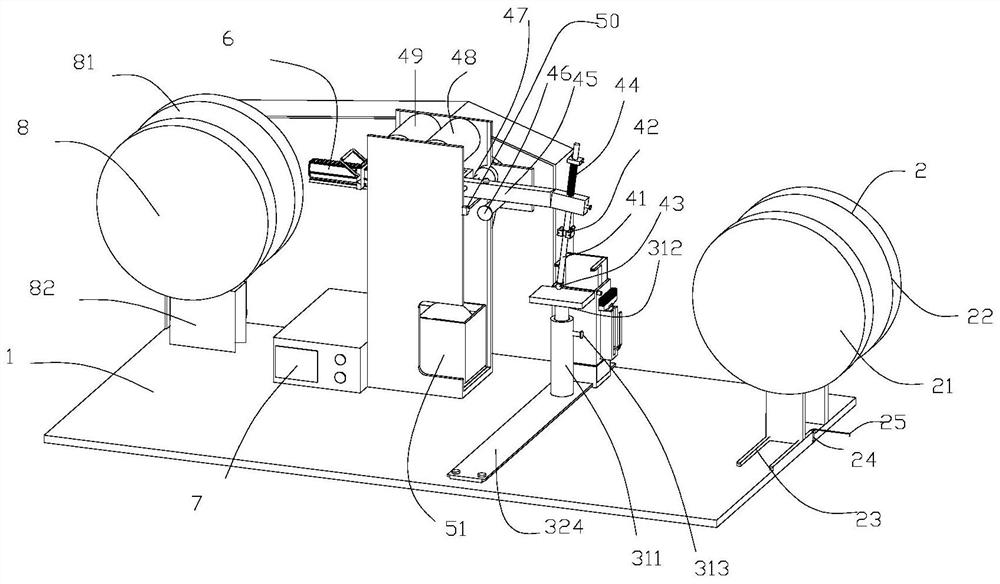

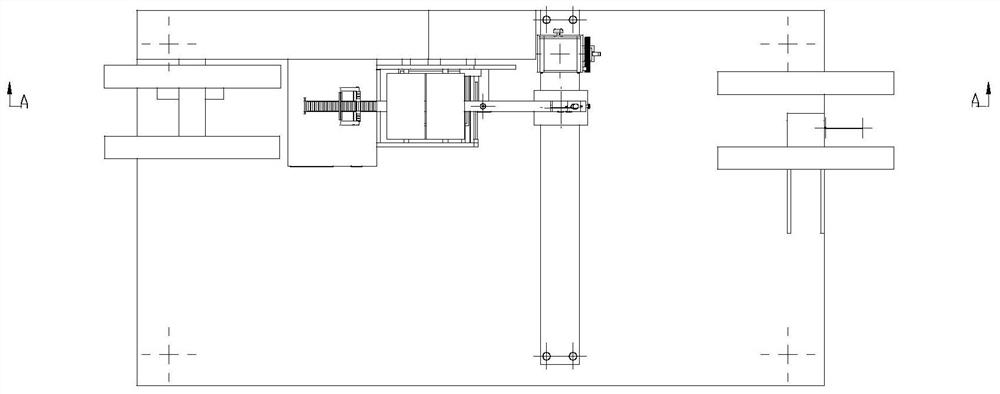

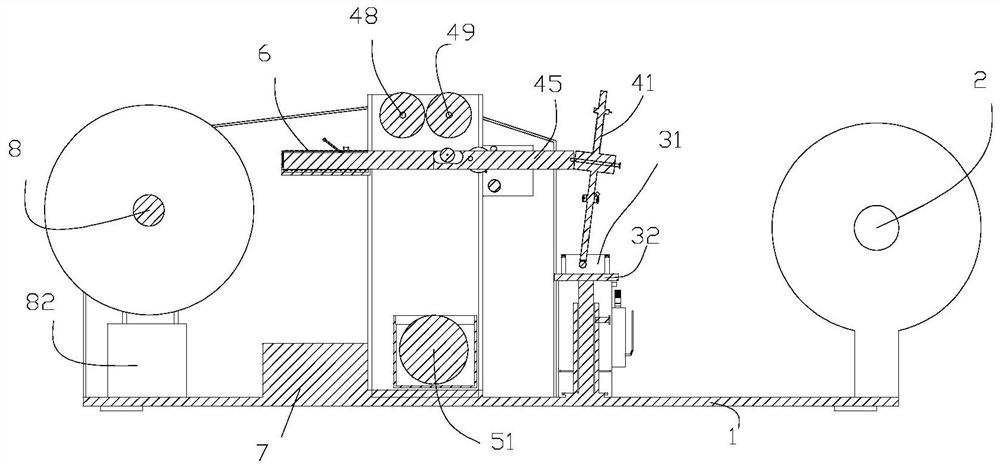

[0020] like Figure 1-5 Shown, a kind of RCA paper tape rubbing machine, comprises machine base 1, paper release mechanism 2, storage table 3, conveying mechanism 4, weight regulator 6, counter 7 and paper delivery mechanism 8; Described paper release mechanism 2 is set At one end of the base 1; the storage table 3, the conveying mechanism 4, the weight regulator 6, and the counter 7 are arranged on the base 1, and the counter is an ordinary counter available on the market, and is no longer To repeat; the delivery mechanism 8 is located at the other end of the base 1 .

[0021] The paper release mechanism 2 includes a first wheel body 21, a second wheel body 22, a chute ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com