Greenhouse planting bracket

A planting frame and support plate technology, applied in the directions of botanical equipment and methods, conveyor control devices, conveyor objects, etc., can solve the problems of large greenhouse space and not the maximum economic efficiency, and achieve the effect of reducing regional problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

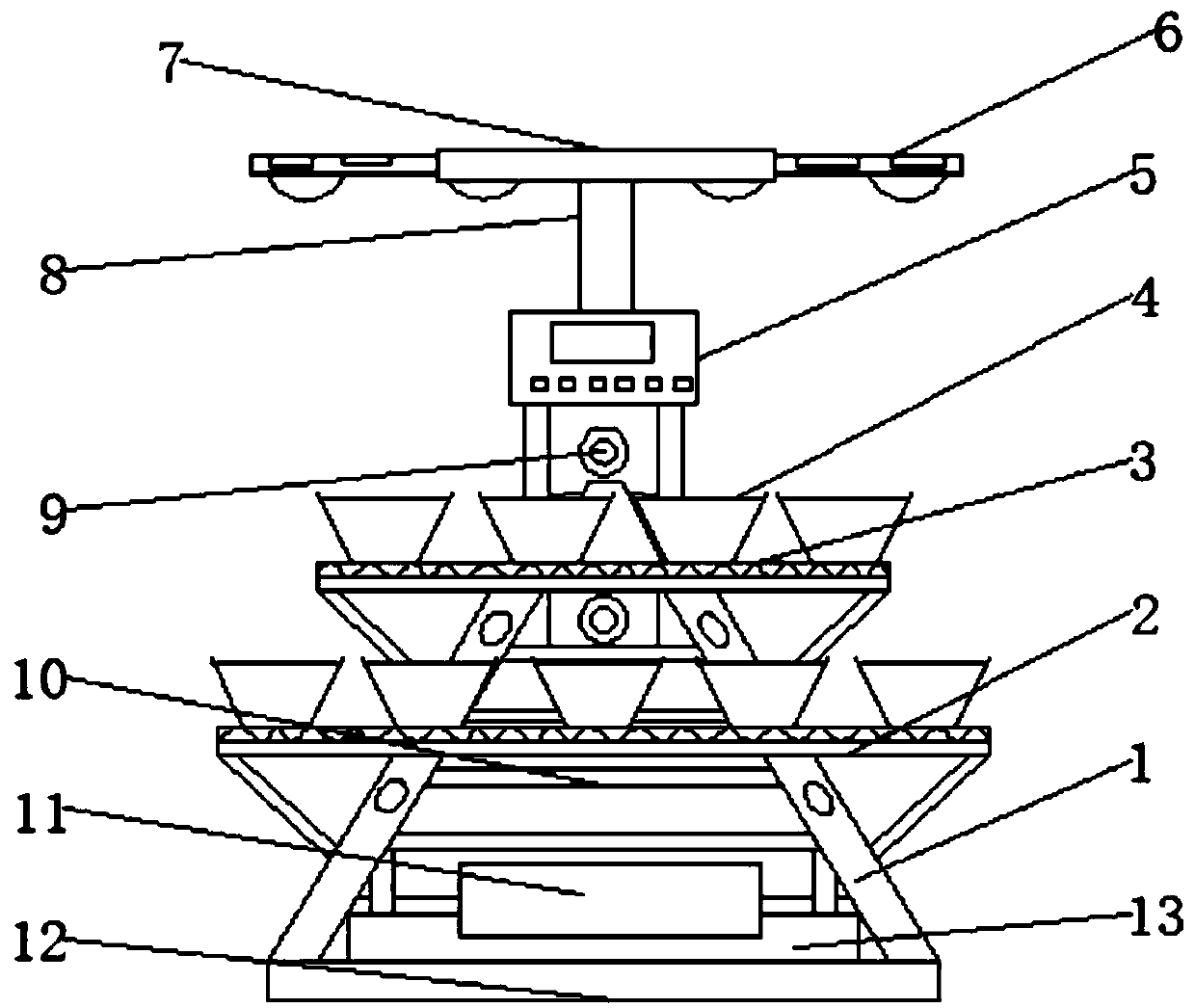

[0016] As a preferred embodiment of the present invention, the interior of the gas replacement chamber 13 is divided into two areas, one communicates with the delivery pipe 9 through a control valve, and the other communicates with the upper part of the planting rack body 1 . The exhaust hole is connected, the telescopic solar panel 6 is embedded in the transmission base 7 , and bulbs are installed at the bottom ends of the telescopic solar panel 6 and the transmission base 7 .

[0017] As a preferred embodiment of the present invention, the bracket body 1 is arranged in a triangular shape and the fixed rods are provided, so that the device can provide a high-strength and high-stability environment during the cultivation process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com