A kind of chemical vapor deposition equipment and film forming method

A chemical vapor deposition and equipment technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of high gas phase parasitic reaction, deterioration of growth film quality, high carbon pollution, etc., to achieve high efficiency transmission , The effect of reducing the frequency of regular maintenance and reducing dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

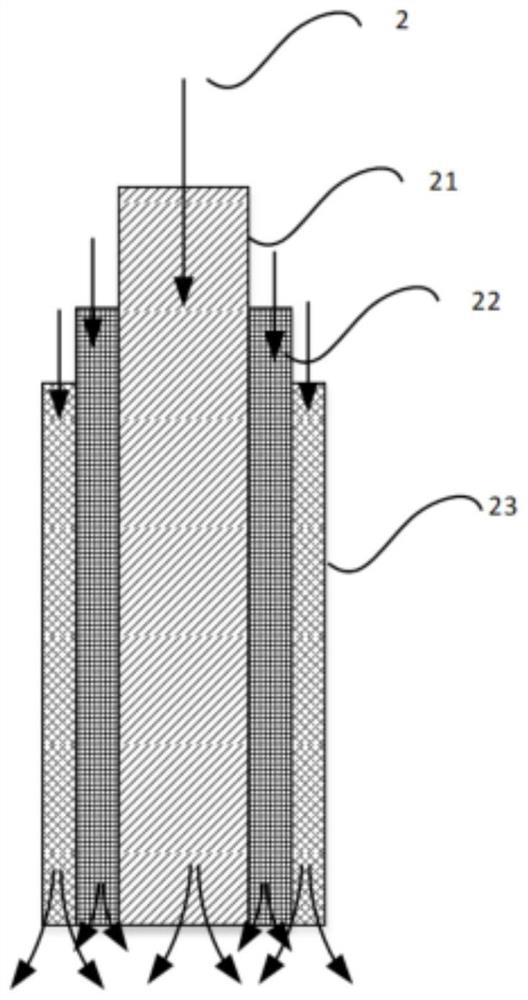

[0062] This embodiment provides a gas input structure, the gas input structure uses a coaxial shower head to inject gas, on the one hand, nitrogen plasma is generated in the near-growth region, and high-energy, high-efficiency, and uniformly distributed nitrogen atom reactants are provided; on the other hand On the one hand, providing an insulating gas to separate the nitrogen plasma from the metal-organic species, better control of the premixed reactants and possible adduct reactions, are considered to be the means to achieve high-quality nitrides using low-temperature metal-organic chemical vapor deposition methods. Key factors for thin film growth.

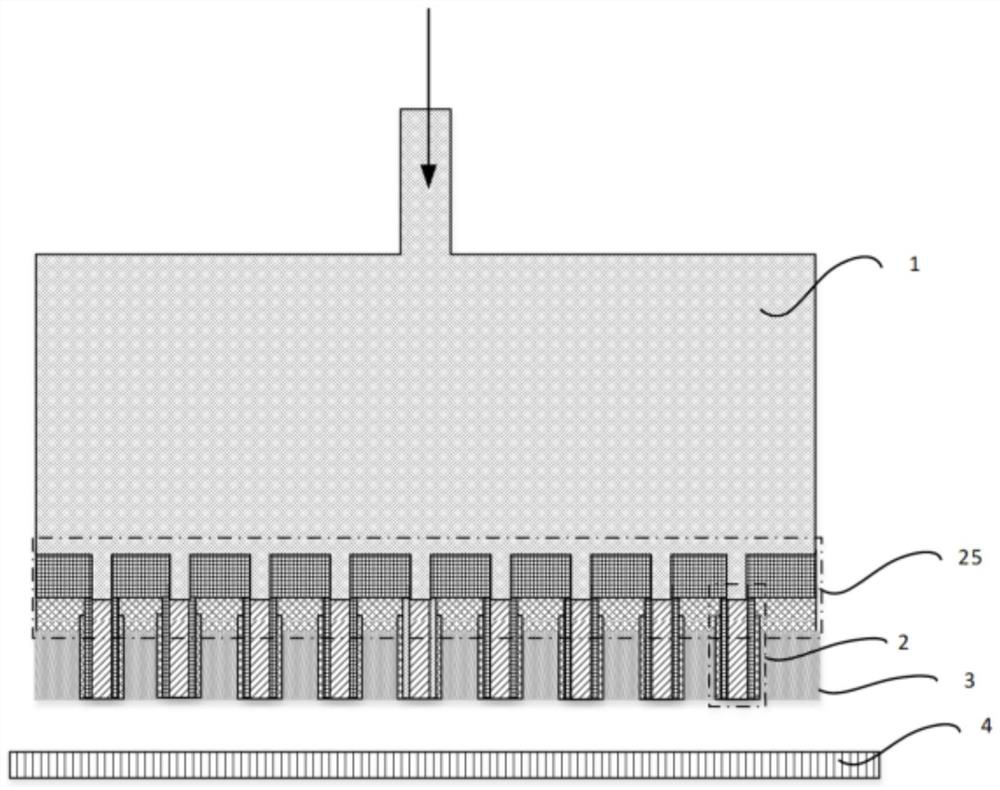

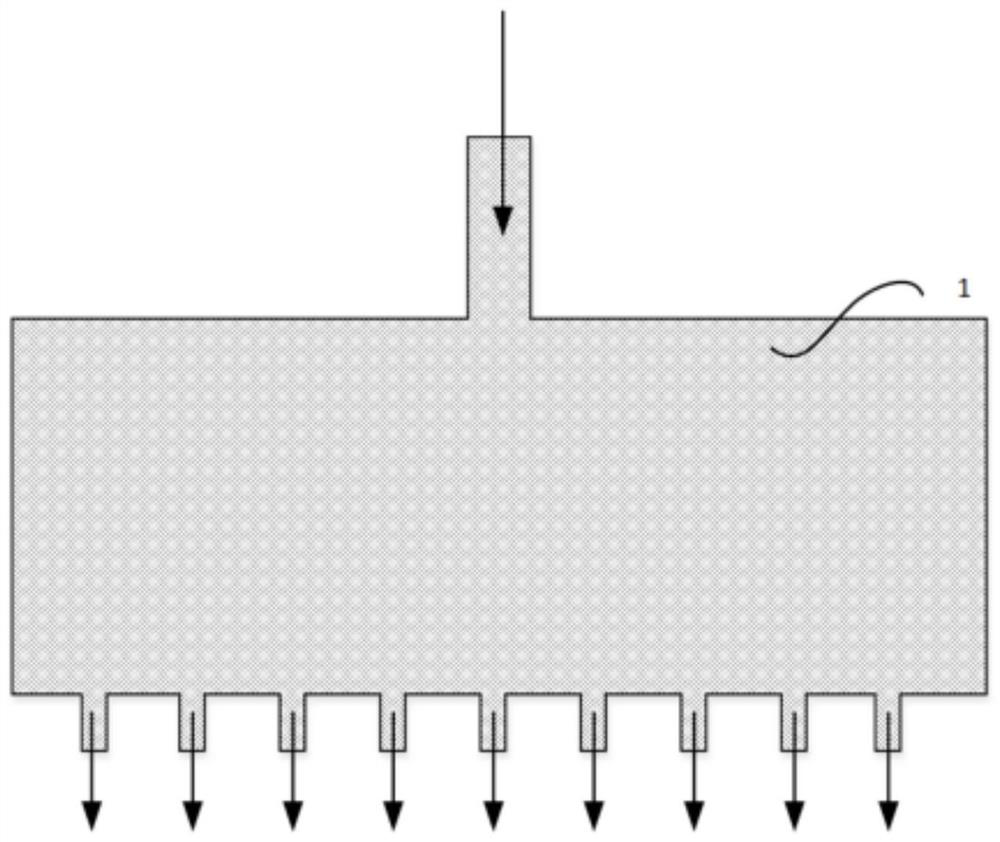

[0063] Such as figure 1 As shown, the gas input structure includes a gas distributor 1 and a plurality of gas outlet sleeves 2 arranged under the gas distributor 1 to achieve uniform gas distribution.

[0064] The gas distributor 1 provides high-efficiency transmission and uniform distribution of the plasma, which is convenien...

Embodiment 2

[0079] This embodiment provides a film forming device, the film forming device includes the gas input structure in Embodiment 1, and realizes the preparation of a thin film by metal-organic chemical vapor deposition.

[0080] The film forming equipment in this embodiment includes a reaction chamber and a plasma generator arranged on the upper part of the reaction chamber, the gas input structure is arranged in the reaction chamber and below the plasma generator, and the outlet of the plasma generator and the gas distribution Corresponding to the entrance of the device, the film forming equipment is especially suitable for the growth of III and IIIA nitride thin films.

[0081] In the film forming process, the space in the first tube 21 is used for plasma transmission, the space between the outside of the first tube 21 and the inside of the second tube 22 is used for additional isolation gas transmission, and the space between the outside of the second tube 22 and the third The...

Embodiment 3

[0099] As another aspect of the present invention, this embodiment also provides a film-forming method based on the film-forming equipment of Embodiment 2, which can be used to produce high-quality Group III nitride films with specific plasma and metal The process conditions of organic matter, compared with the existing metal organic chemical vapor deposition technology and process, the process and conditions improve the film growth at low temperature, and importantly, it greatly reduces the growth temperature and reduces the process cost.

[0100] Such as Figure 6 Shown, film-forming method comprises steps:

[0101] Step S1): Evacuate the reaction chamber to the reference pressure, place the film-forming substrate above the base in the reaction chamber, and set the temperature of the film-forming substrate to the first temperature.

[0102] The core of the film forming method is to form a film on the substrate 4 to be filmed in the reaction chamber 6 by adjusting the pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com