Bendable protective film for high-flexibility curved screen and preparation method of bendable protective film

A flexible and curved screen technology, applied in the field of film materials, can solve problems such as insufficient bending resistance, scratch resistance, and insufficient bending resistance, so as to improve overall performance, improve light transmission performance, and excellent bending resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The present invention also provides a method for preparing the bendable protective film for highly flexible curved screens, including the following steps:

[0051] 1) Preparation of flexible modified PET layer 2: PET, polybutylene terephthalate, hydroxyl-terminated hyperbranched polyester, polypentylene glycol dibenzoate, calcium silicate, calcium benzoate , nano-titanium dioxide, composite modifier, and stabilizer are added into the reaction vessel, heated to 150-350° C., stirred for 1.5-4 hours, cooled and formed to obtain the flexible modified PET layer 2;

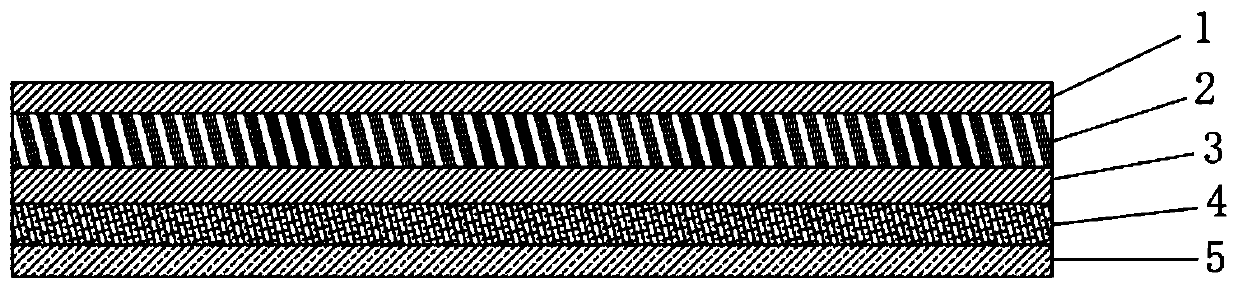

[0052] 2) The first flexible HC treatment layer 1 and the second flexible HC treatment layer 3 are respectively coated on the surface and the bottom surface of the flexible modified PET layer 2, and the adhesive layer prepared by coating on the second flexible HC treatment layer 3 4;

[0053] 3) drying in an oven, and pasting the release layer 5 on the adhesive layer 4 .

Embodiment 1

[0056] A bendable protective film for a highly flexible curved screen, comprising a first flexible HC-treated layer 1 (20 μm), a flexible modified PET layer 2 (30 μm), and a second flexible HC-treated layer 3 (15 μm) stacked in sequence , adhesive layer 4 (20 μm) and release layer 5 (20 μm);

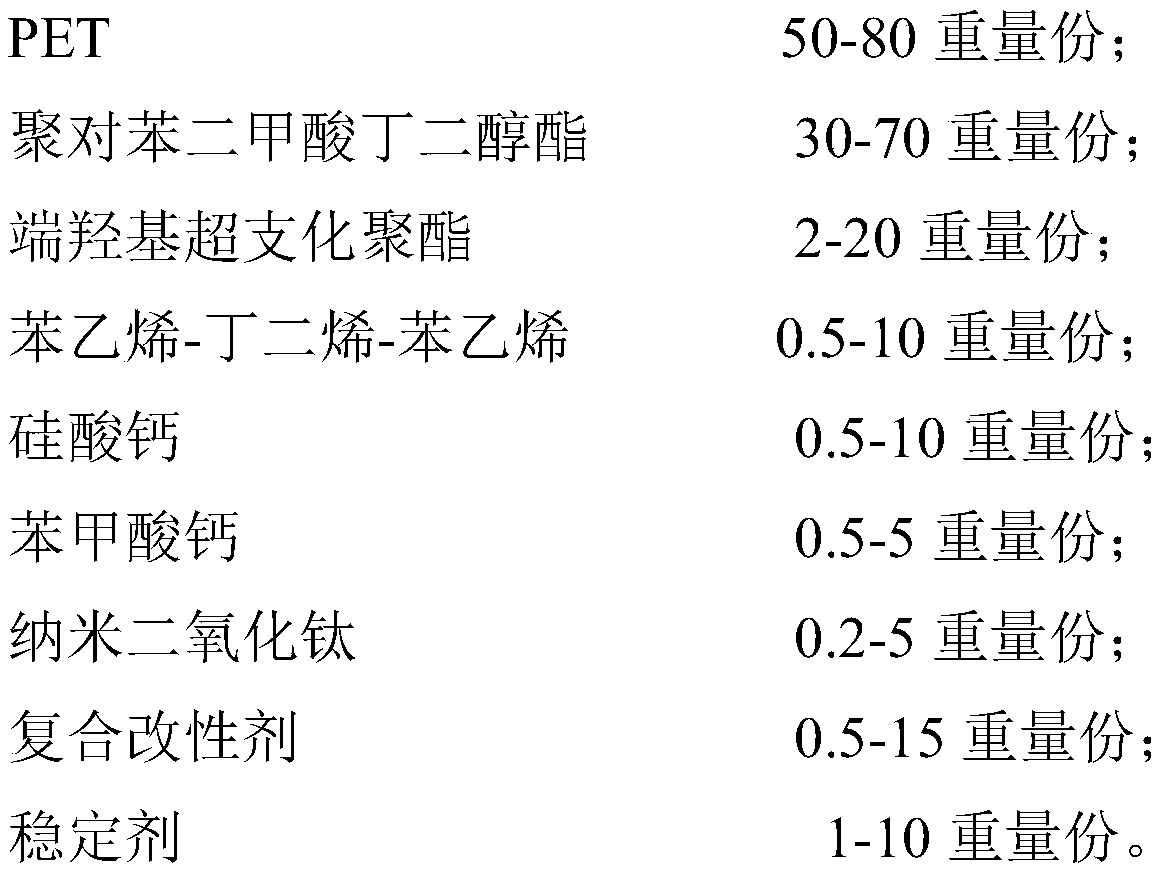

[0057] Wherein, the raw material of flexible modified PET layer 2 comprises by weight:

[0058]

[0059]

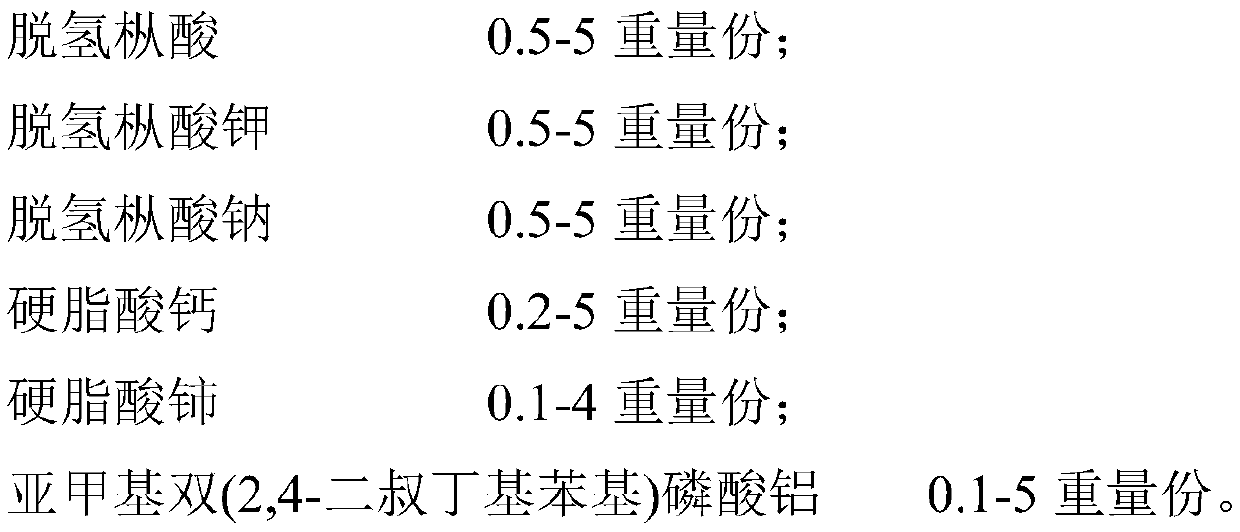

[0060] Wherein, the raw material of compound modifier comprises by weight:

[0061]

[0062] The preparation method of the bendable protective film for the highly flexible curved screen comprises the following steps:

[0063] 1) Preparation of flexible modified PET layer 2: PET, polybutylene terephthalate, hydroxyl-terminated hyperbranched polyester, polypentylene glycol dibenzoate, calcium silicate, calcium benzoate , nano-titanium dioxide, composite modifier, and stabilizer are added to the reaction vessel, heated to 280° C., stirred for 3 hours, cooled and formed to ob...

Embodiment 2

[0067] A bendable protective film for a highly flexible curved screen, the raw materials of the flexible modified PET layer 2 include by weight:

[0068]

[0069]

[0070] The raw material of compound modifier comprises by weight:

[0071]

[0072] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com