Single-component biodegradable printing ink for plastic printing and preparation method thereof

A biodegradable plastic, one-component technology, applied in the field of printing ink, can solve the problems of difficult biodegradation, organic solvent pollution, heavy metal pollution, etc., and achieve the effect of wide application range and strong bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

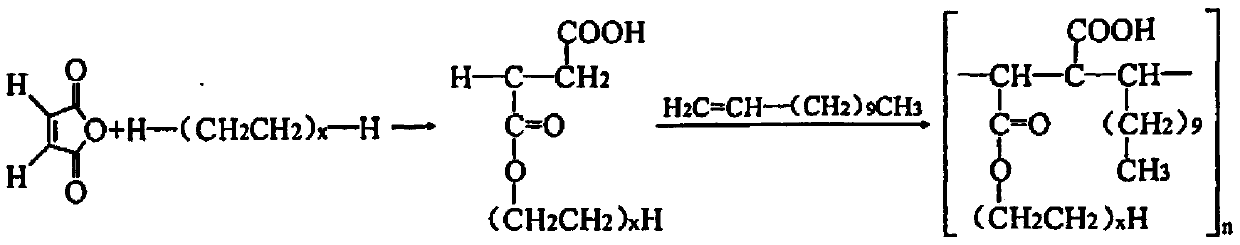

Method used

Image

Examples

preparation example Construction

[0049] A second aspect of the present invention provides a method for preparing the above-mentioned one-component biodegradable plastic printing ink, which includes the following steps:

[0050] (1) Dissolution of film-forming agent and linking resin: add water to the dissolution kettle, add film-forming agent under stirring, add linking resin and continue stirring until the linking resin is completely dissolved, cool the obtained mixed solution and discharge , the filtrate obtained after filtration obtains solution A after natural cooling;

[0051] (2) Mixing of other components: Add colorant and remaining preparation raw materials to solution A, pre-disperse and mix the resulting mixture with a disperser to obtain mixed solution B;

[0052] (3) Sand milling of the mixed solution: put the mixed solution B in a sand mill and add a solvent for sanding, and filter the obtained mixed solution to obtain the single-component biodegradable plastic printing ink.

[0053] Further, in...

Embodiment 1

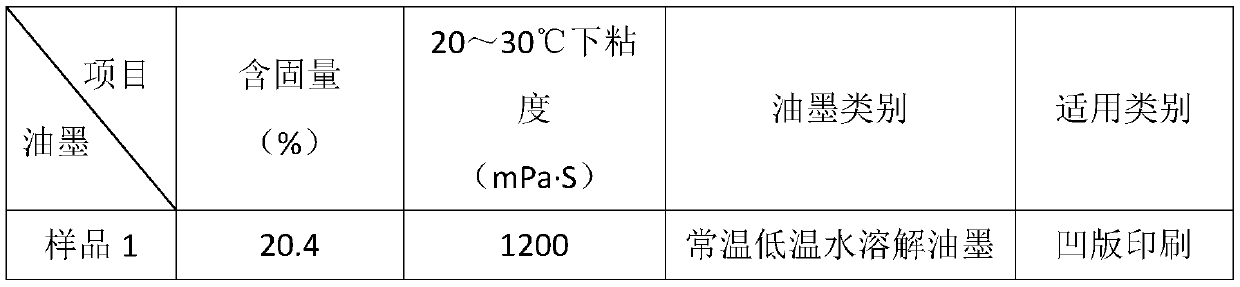

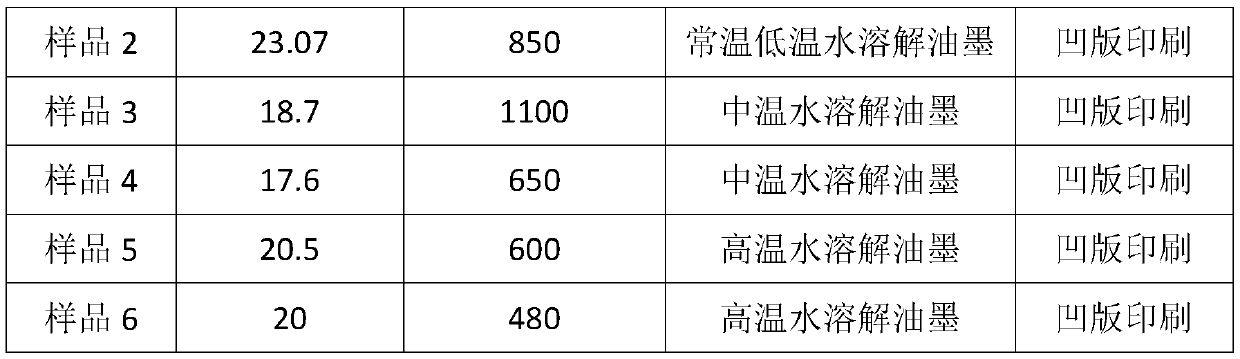

[0066] A sample of environmentally friendly printing ink dedicated to biodegradable PVA plastics and bio-based modified plastics 1

[0067] 1) Dissolution of film-forming agent and linking resin: add 480g of water to the dissolution tank, and add 15g of N,N-dimethylformamide and 5g of polypropylene glycol (molecular weight: 200) under stirring at a speed of 350rpm , then after adding 70g of PVA resin (specification 088-05), 20g of PVA resin (specification 088-08) and 10g of PVA resin (specification 088-20), after the rotation speed is 400rpm and continuous stirring for 30min, in the dissolution tank Heat the resulting mixture with hot oil in the jacket, keep a constant temperature of 95°C, stir at a speed of 800rpm for 30min, then stir at a speed of 350rpm for 3h, take a sample through a scraper and visually check that there are no solid particles, and immediately close the clamp Heating the jacket, opening the jacket circulating cooling water system, cooling the obtained mixe...

Embodiment 2

[0072] A sample of environmentally friendly printing ink dedicated to biodegradable PVA plastics and bio-based modified plastics 2

[0073] 1) Dissolution of the film-forming agent and the linking resin: add 400g of water to the dissolving tank, and add 5g of N,N-dimethylformamide and 25g of N-ethylpyrrolidone under the stirring state of 350rpm, and then After adding 100g of PVA resin (specification 088-05), continue stirring at a speed of 400rpm for 30 minutes, then heat the mixture with hot oil in the jacket of the dissolution kettle, keep the constant temperature at 95°C, and stir at a speed of 800rpm After 30 minutes, stir at a speed of 350rpm for 3 hours, take a sample through a scraper and visually check that there are no solid particles, immediately turn off the jacket heating, turn on the jacket circulating cooling water system, and cool the resulting mixed solution to 30°C before entering the diaphragm pump. After filtering with a filter membrane with a pore size of 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com