Double-layer skin wave-absorbing composite material sandwich structure and preparation method thereof

A technology of composite materials and sandwich structures, applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve problems such as difficulty in obtaining wave-absorbing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

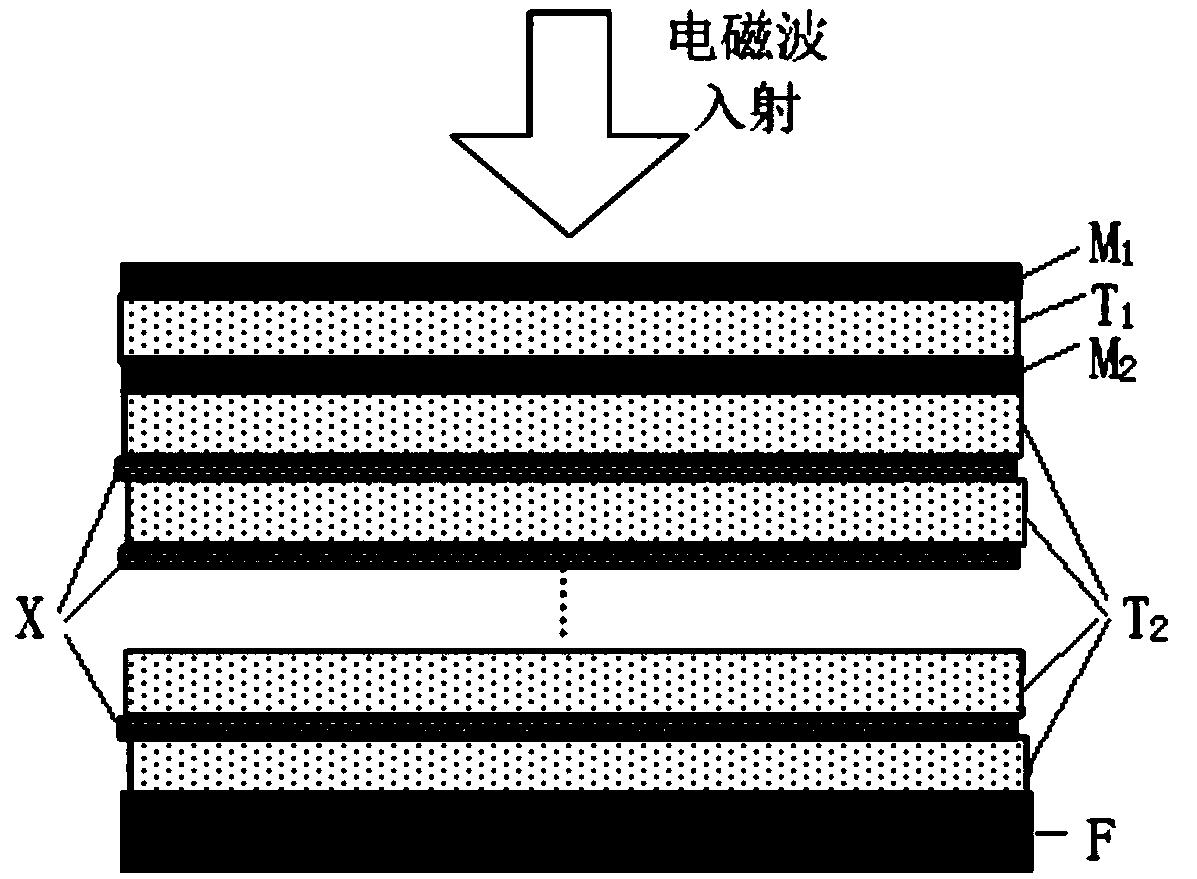

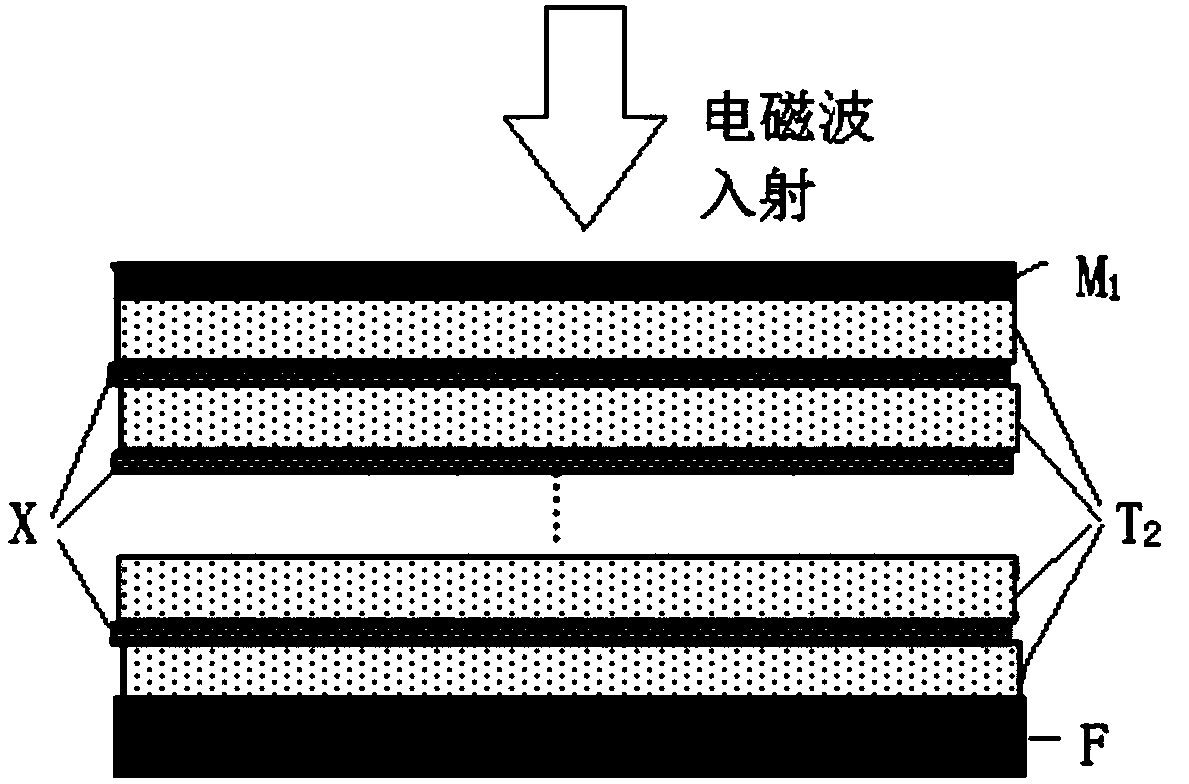

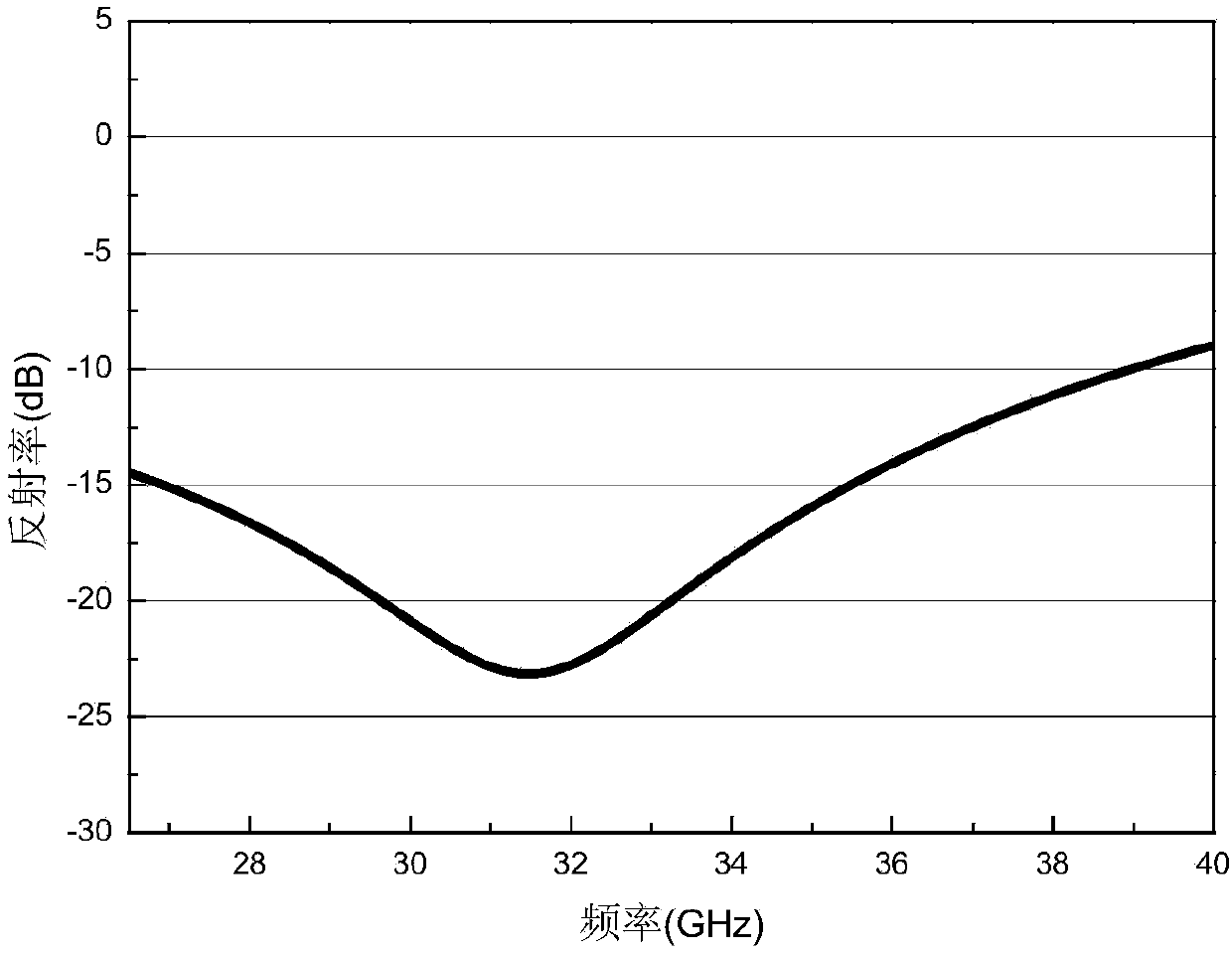

[0060] In the sandwich structure of double-skin absorbing composite materials provided in this embodiment, the first skin layer M 1 and the second skin layer M 2 The materials used are all glass fiber fabric reinforced resin composite materials with a thickness of 1mm; the wave-transmitting layer T 1 The selected material is polyurethane foam with a thickness of 0.5mm; the wave-transmitting layer T 2 There are four layers in total, all of which are made of polyurethane foam with a thickness of 3mm; the wave-absorbing layer X has four layers in total, all of which are made of epoxy adhesive mixed with carbon black wave-absorbing composite materials, along the direction of electromagnetic wave propagation, four layers The mass percentages of carbon black in the wave-absorbing layer X are 0.1%, 0.5%, 2%, and 6% respectively; the material selected for the reflective layer F is carbon fiber fabric reinforced resin composite material.

[0061] The preparation method of the present...

Embodiment 2

[0073] In the sandwich structure of double-skin absorbing composite materials provided in this embodiment, the first skin layer M 1 and the second skin layer M 2 The materials used are all quartz fiber fabric reinforced resin composite materials with a thickness of 0.6mm; the wave-transmitting layer T 1 The selected material is epoxy foam with a thickness of 0.5mm; the wave-transmitting layer T 2 There are four layers in total, all of which are made of epoxy foam with a thickness of 3mm; the wave-absorbing layer X has four layers, all of which are made of cyanate adhesive mixed with graphene wave-absorbing composite materials, along the direction of electromagnetic wave propagation , in the four absorbing layers X, the mass percentages of carbon black are 0.1%, 0.4%, 1.2%, and 2.2% respectively; the reflective layer F is made of carbon fiber fabric reinforced resin composite material.

[0074] The preparation method of the present embodiment comprises the following steps:

...

Embodiment 3

[0086] In the sandwich structure of double-skin absorbing composite materials provided in this embodiment, the first skin layer M 1 and the second skin layer M 2 The materials used are all aramid fiber fabric reinforced resin composite materials with a thickness of 0.3mm; the wave-transmitting layer T 1 The selected material is aramid paper honeycomb with a thickness of 0.5mm; the wave-transmitting layer T 2 There are six layers in total, and the materials selected are all aramid paper honeycombs with a thickness of 2mm; the wave-absorbing layer X has six layers in total, and the materials selected are Shuangma resin adhesive mixed with chopped carbon fiber wave-absorbing composite materials, along the electromagnetic wave In the direction of propagation, the mass percentages of chopped carbon fibers in the six absorbing layers X are 0.1%, 0.5%, 1.2%, 2%, 4%, and 6% respectively; the material selected for the reflective layer F is carbon fiber fabric reinforced resin composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com