Curved surface shaped medical device having antibacterial coating and preparation method thereof

A curved surface modeling and medical device technology, applied in the direction of coatings, catheters, etc., can solve the problems of film-forming aid residues, safety risks, etc., and achieve the effect of ensuring sterilization performance, good adaptability, and reducing the risk of bacterial infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment relates to a method for preparing a curved medical device with an antibacterial coating, comprising the following steps:

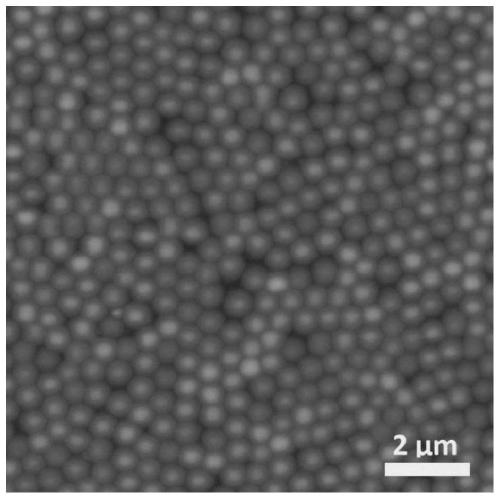

[0032] S1, 8mmol of N-vinylcaprolactam, 1.2mmol of vinylimidazole and 1.2mmol of 1,6-dibromohexane were added to a three-necked flask containing 198mL of deionized water, stirred slowly, and introduced inert gas nitrogen and Under the condition of condensing and reflux, raise the temperature to 70°C and keep it warm for 10 minutes; then add 2 mL of deionized water containing 100 mg of azobisisobutylamidine hydrochloride to initiate the reaction; continue to blow nitrogen, stir at a medium speed of 350-500 rpm, and condense and reflux Under the conditions, the reaction was continued for 8 hours; finally, the temperature was slowly cooled to room temperature to obtain quaternary ammonium salt type poly(N-vinylcaprolactam) microgel particles with a particle size between 300-400nm;

[0033] S2, dispersing the quaternary ammonium salt typ...

Embodiment 2

[0039] This embodiment relates to a method for preparing a curved medical device with an antibacterial coating, comprising the following steps:

[0040] S1, 8mmol of N-vinylcaprolactam, 2.4mmol of vinylimidazole and 1.2mmol of 1,8-dibromooctane were added to a three-necked flask containing 198mL of deionized water, under the conditions of slow stirring, nitrogen flow and condensing and reflux , heat up to 70°C, and keep warm for 10 minutes; then add 2 mL of deionized water containing 150 mg of azobisisobutylamidine hydrochloride to initiate the reaction; under the conditions of continuous nitrogen flow, 350-500 rpm medium-speed stirring and condensing and reflux, Continue to react for 8 hours; finally, the temperature is slowly cooled to room temperature to obtain quaternary ammonium salt type poly(N-vinyl caprolactam) microgel particles with a particle diameter between 400-500nm;

[0041] S2, dispersing the quaternary ammonium salt type poly(N-vinyl caprolactam) microgel part...

Embodiment 3

[0044] This embodiment relates to a method for preparing a curved medical device with an antibacterial coating, comprising the following steps:

[0045] S1. Add 8mmol of N-isopropylacrylamide, 1.2mmol of vinylimidazole and 0.6mmol of 1,5-dibromobutane into a three-necked flask containing 198mL of deionized water, stir slowly, blow nitrogen and condense Under reflux conditions, raise the temperature to 70°C and keep it warm for 10 minutes; then add 2 mL of deionized water containing 150 mg of azobisisobutylamidine hydrochloride to initiate the reaction; The reaction was continued for 8 hours; finally, the temperature was slowly cooled to room temperature to obtain quaternary ammonium salt type poly(N-isopropylacrylamide) microgel particles with a particle diameter between 350-500nm;

[0046] S2, dispersing the quaternary ammonium salt type poly(N-vinyl caprolactam) microgel particles prepared in S1 in ethanol to make a dispersion;

[0047] S3, using the dip coating method to c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com