A kind of tree core groove processing method and printed circuit board

A printed circuit board and groove processing technology, which is applied in the direction of printed circuit, printed circuit manufacturing, electrical components, etc., can solve the problems affecting the installation of components, so as to improve the quality and prevent the front edge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

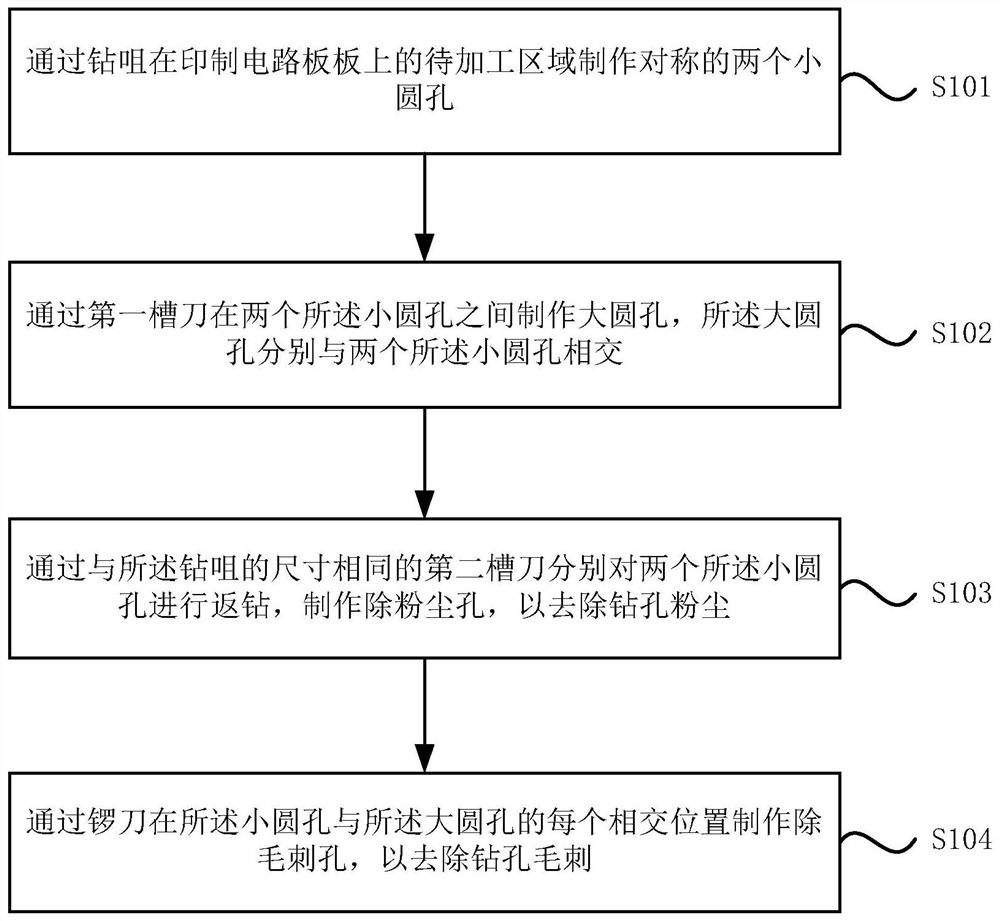

[0032] Please refer to the attached image 3 It is a schematic flowchart of a method for processing a tree core groove provided by Embodiment 1 of the present invention, and the method is applicable to the scene of processing a tree core groove. The method specifically includes the following steps:

[0033] S101, make two symmetrical small round holes on the area to be processed on the printed circuit board through the drill bit, such as Figure 4 shown;

[0034] It should be noted that there are two types of core grooves: horizontal and vertical. In this embodiment, the horizontal core groove is taken as an example, and the same is true for vertical.

[0035] Preferably, before the step S101, the method further includes:

[0036] According to the size of the small round hole to be drilled, select a drill bit that matches the size.

[0037] S102. Make a large circular hole between the two small circular holes through the first groove cutter, and the large circular hole int...

Embodiment 2

[0050] Embodiment 2 of the present invention provides a printed circuit board, which has a core groove, and the core groove is manufactured by the core groove processing method as described in Embodiment 1.

[0051] A printed circuit board provided by an embodiment of the present invention can completely remove burrs and fibers by adding drilling holes for removing burrs, dust, and fibers in the processing process, and prevent the burr after copper electroplating, so as to achieve It meets the requirements of component installation and improves the quality of slot hole processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com