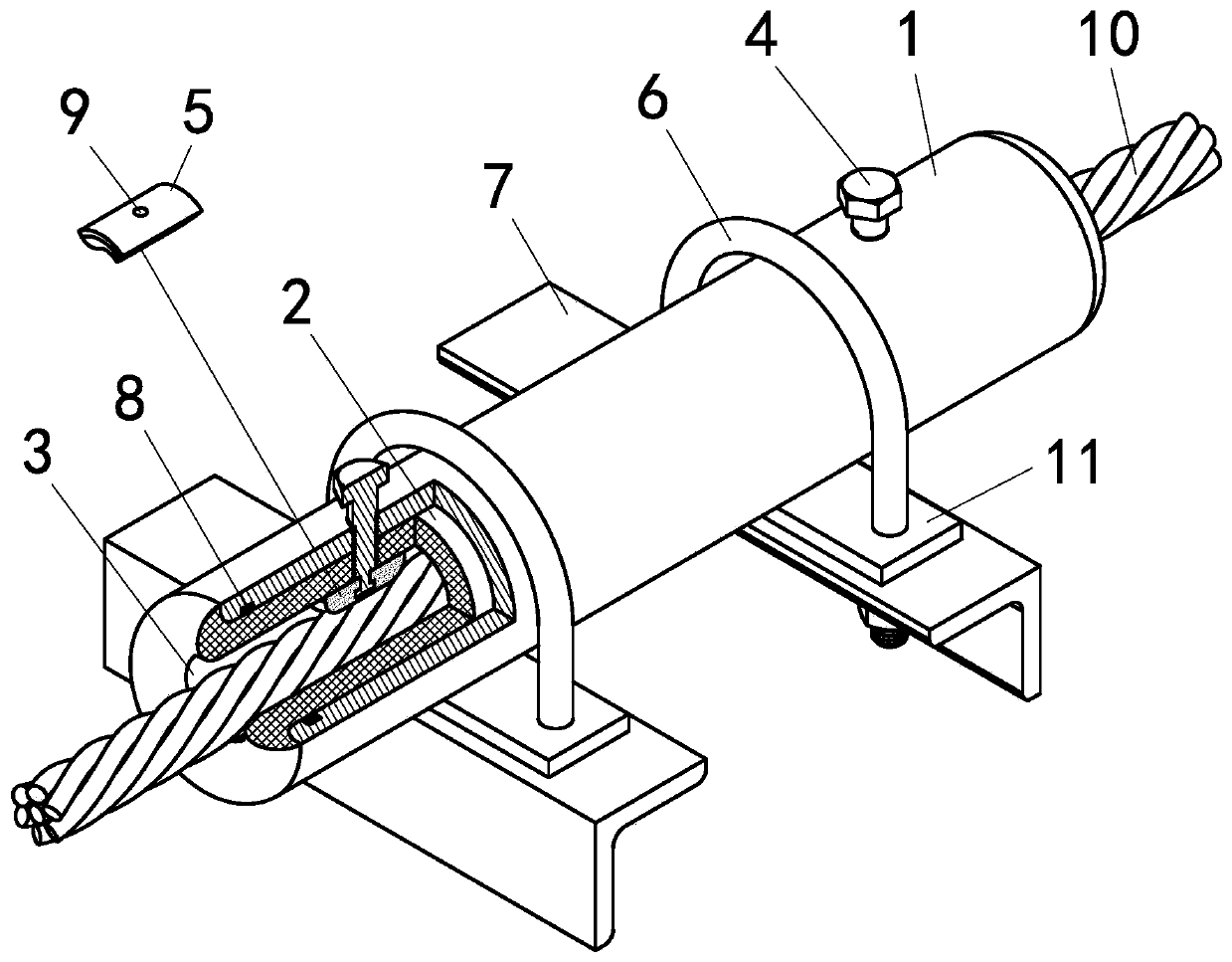

Threading cable fixing device

A technology for fixing devices and cables, applied in cable installation, cable space arrangement/configuration, electrical components, etc., can solve problems such as fault accidents, insulator failure, fatigue failure, etc., to improve the ability to deal with severe weather, reduce losses, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0015] A kind of threading type cable fixing device of the present invention, during specific implementation, such as figure 1 As shown, it includes a support tube 1, an insulating tube 2, a clip 5, a compression bolt 4, a U-shaped card 6 and other components. The supporting tube 1 is the supporting body of the whole device, and is required to be made of a material with high strength and good corrosion resistance. For example, it can be made of porcelain materials with good crack resistance, or stainless steel with good strength and corrosion resistance. The support tube 1 is provided with an insulating tube 2, which can be pressed into the support tube 1 by molding or inlaid process. The insulating tube 2 is provided with bell mouth 3 arc flanging, one is to avoid scratching the cable 10, and the other is to wrap the support tube 1 through the bell mouth 3 arc flanging of the insulating tube 2 to prevent the cable 10 from contacting the support tube 1. In order to prevent r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com