Preparation method of N-doped Co nanocluster/N-doped porous carbon/S composite material for positive electrode of high-performance potassium-sulfur battery

A technology of composite materials and nano-clusters, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of unclear reaction mechanism, affecting the electrochemical performance of potassium-sulfur batteries, and limiting the application of potassium-sulfur batteries, so as to improve the performance of graphite degree of oxidation, reduction of agglomeration, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

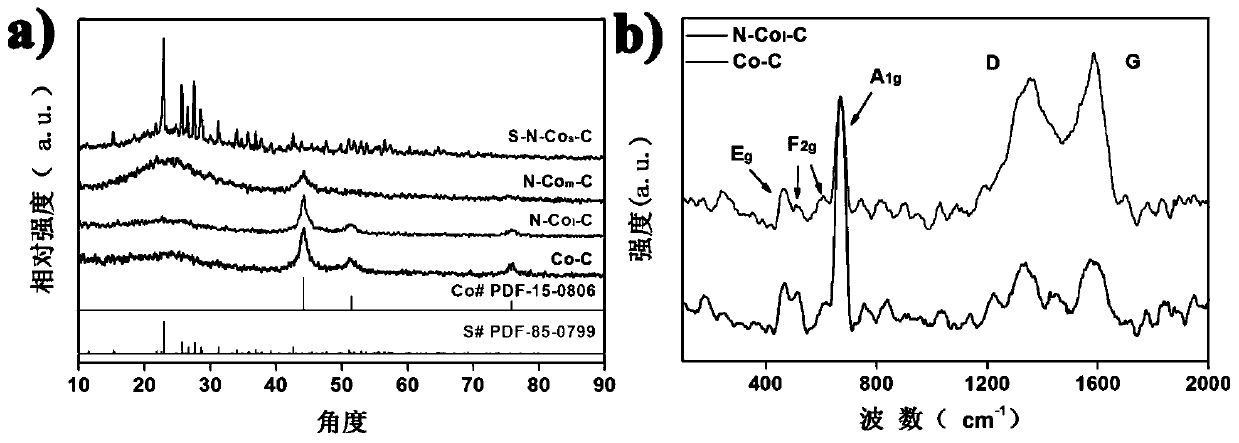

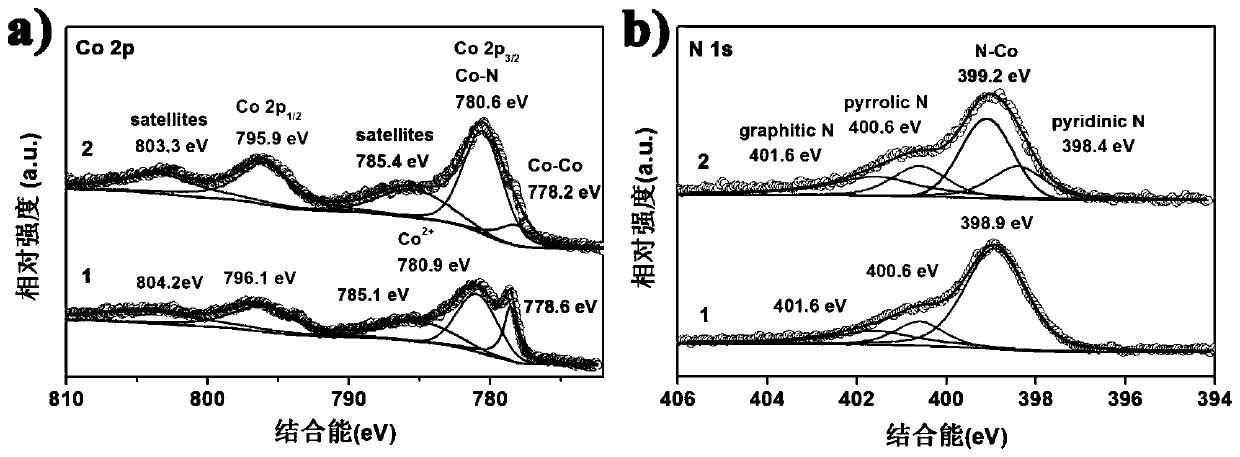

[0032] A method for preparing an N-doped Co nanocluster / N-doped porous carbon / S composite material for a positive electrode of a high-performance potassium-sulfur battery, comprising steps:

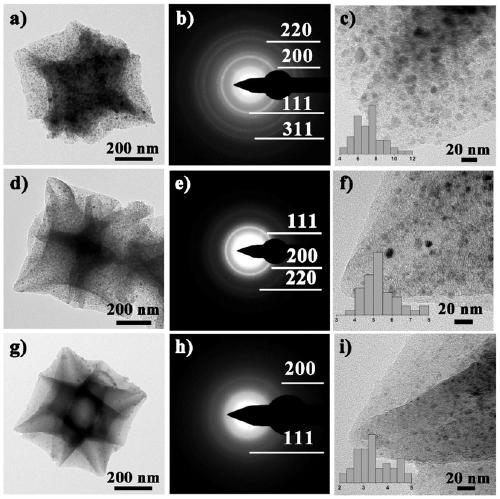

[0033] (1) 4.98g Co(NO 3 ) 2 ·6H 2 O was dissolved in 500ml of methanol solution and mixed uniformly to obtain solution A; 6.56g of 2-methylimidazole was dissolved in 500ml of methanol solution and mixed uniformly to obtain solution B; solution B was slowly added dropwise to solution A while stirring, at room temperature After stirring for 30 minutes, stand at room temperature for 24 hours, then centrifuge, wash with methanol, and dry at 60°C for 24 hours to obtain ZIF-67. According to the thermogravimetric test, the initial carbonization temperature of the prepared ZIF-67 is 435°C.

[0034] (2) Place the prepared ZIF-67 in a calciner, calcined in a nitrogen atmosphere, raise the temperature to 435°C for 6h, then raise the temperature to 600°C for 2h, and the heating rate in the above ...

Embodiment 2

[0043] A kind of preparation method of N-doped Co nanocluster / N-doped porous carbon / S composite material used for positive electrode of high-performance potassium-sulfur battery, as described in Example 1, the difference is:

[0044] In step (2), the prepared ZIF-67 was placed in a calciner, calcined in a nitrogen atmosphere, raised to 435°C for 6h, then raised to 550°C for 2h, and the heating rate in the above process was 2°C / min . Then soak 1 g of the above calcined product in 50 mL of 2 mol / L sulfuric acid aqueous solution at room temperature for 6 h to obtain the N-doped Co nanoparticles / N-doped porous carbon composite material.

[0045] Other steps and conditions are consistent with Example 1.

Embodiment 3

[0047] A kind of preparation method of N-doped Co nanocluster / N-doped porous carbon / S composite material used for positive electrode of high-performance potassium-sulfur battery, as described in Example 1, the difference is:

[0048] In step (3), the prepared N-doped Co nanoparticles / N-doped porous carbon composite material and sulfur were uniformly mixed at a mass ratio of 1:1, sealed in a glass tube under vacuum, treated at 155°C for 20h, and then The temperature was raised to 280 °C for 1 h, and the heating rate was 2 °C / min. With the evaporation of S, the Co particles were further cracked into nano-clusters, and N-doped Co nano-clusters / N-doped porous carbon / S composite materials were obtained.

[0049] Other steps and conditions are consistent with Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com