A high-efficiency anode tube for ion source

An anode tube and ion source technology, applied in the field of electron sources, can solve problems such as uneven distribution of reactive gases, low adsorption efficiency of electronic dust, and reduced working efficiency of ion sources, so as to expand adsorption points, save materials, and avoid overall replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

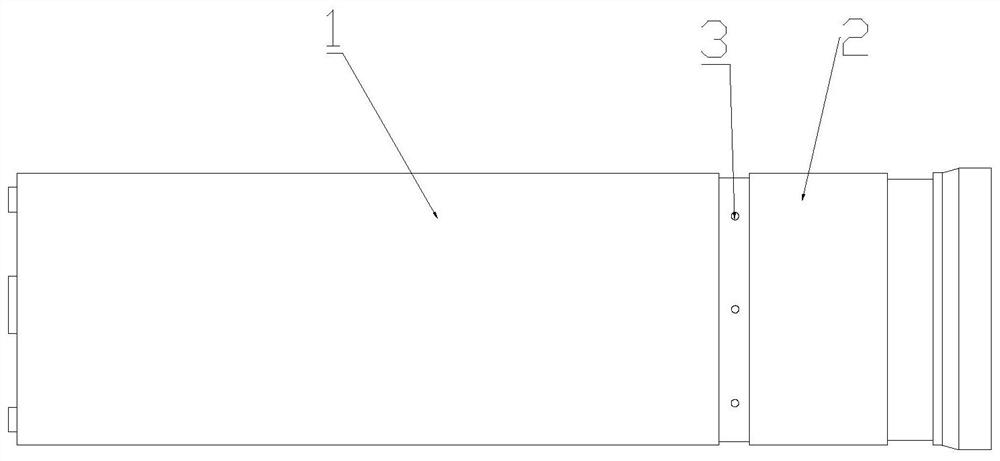

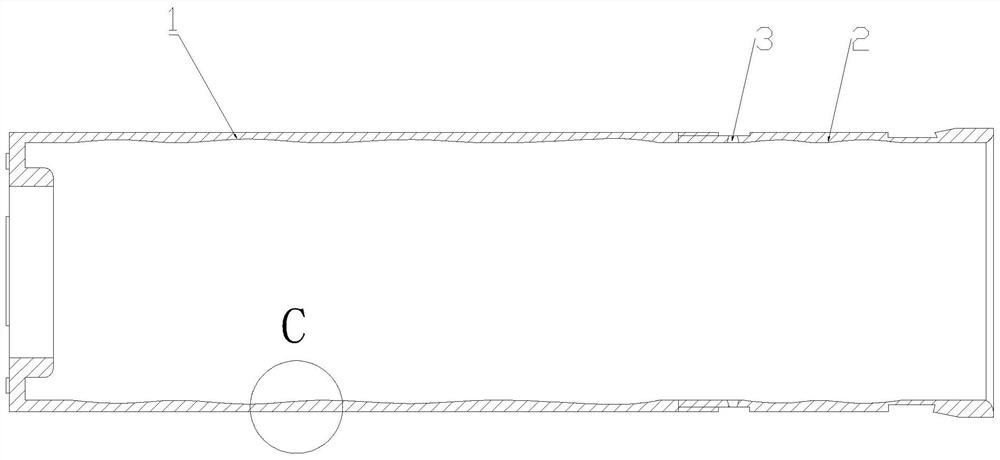

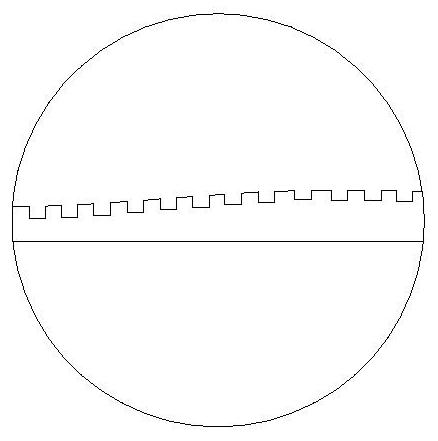

[0015] As shown in the manual Figure 1 to Figure 3 The shown high-efficiency anode tube for ion source includes a first anode tube 1 and a second anode tube 2, the first anode tube 1 and the second anode tube 2 are sleeved together with each other, and the first anode tube 1 and the second anode tube The inner wall of the anode tube 2 is wave-shaped, and the inner walls of the first anode tube 1 and the second anode tube 2 are uneven, and the unevenness can be obtained by sandblasting, chemical treatment or mechanical treatment. One end is provided with a vent hole 3 along the circumference, and the inner diameter of the vent hole 3 is small on the outside and large on the inside.

[0016] The first anode tube 1 and the second anode tube 2 are screwed and sleeved together by means of threaded connection, and the connection is detachable. Which part is damaged and which part is replaced, so as to avoid overall replacement.

[0017] The first anode tube 1 and the second anode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com