Numerical control machining process parameter self-adaptive control method

An adaptive control and mechanical processing technology, applied in the field of mechanical processing, can solve problems such as parameter variation range instability and product quality impact, and achieve the effects of precise control, ideal quality, and improved control methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

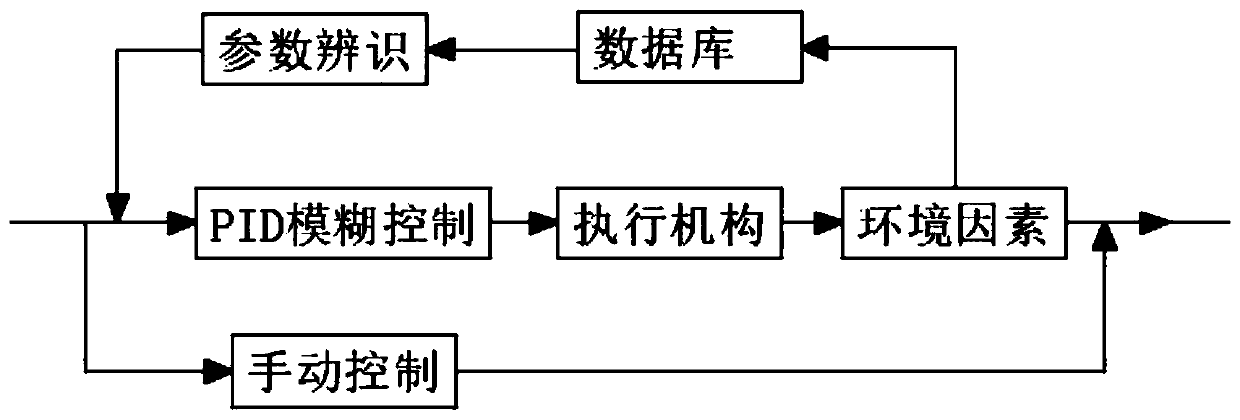

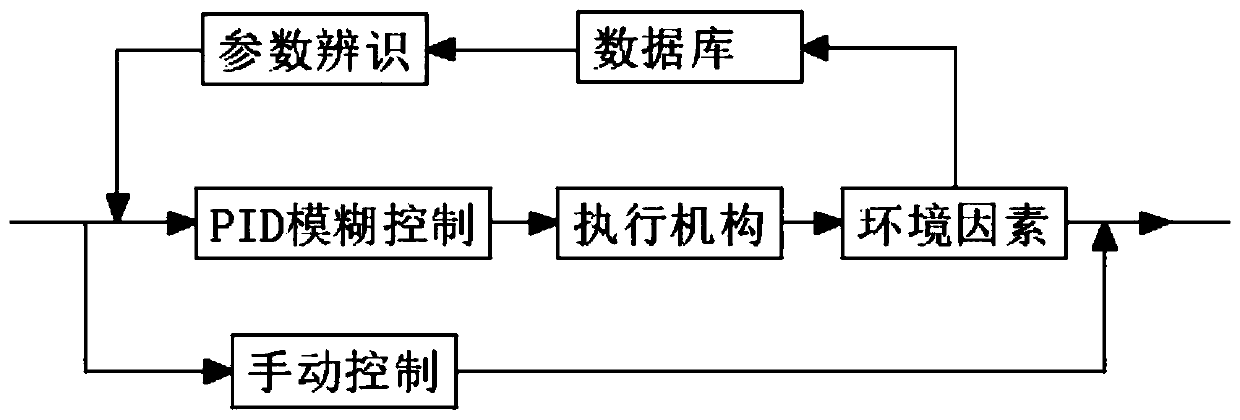

[0020] Such as Figure 1-2 As shown, the present invention provides a technical solution: a method for adaptive control of numerical control machining process parameters, based on a database of mechanical processing process adaptive parameters, the database includes an input module and a crawler module, and the input module is convenient for staff to manually adjust most process parameters. The input process is convenient for the staff to improve or update the parameter data in time. The crawler module can establish a connection with the target network, which is convenient for timely improvement of the data in the database. Information parameters, establish a mathematical control model of the machining process, and extract data feature quantities according to the characteristics of the parameters. The established mathematical control model accurate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com