A thermocouple positioning device for thermal process equipment and its accuracy verification method

A technology of positioning device and calibration method, which is applied to thermometers and measuring devices using electrical devices, electrical/magnetic components directly sensitive to heat, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in connection with the examples, but the embodiments of the present invention are not limited thereto.

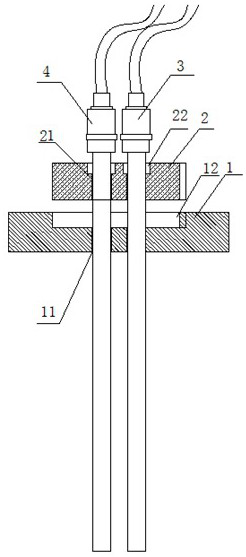

[0033] like figure 1 , The positioning device thermocouple heat process apparatus for mounting a thermocouple, comprising a chassis 1, the chassis 1 is mounted on the thermal processing apparatus, provided with at least two internal thermal process equipment communication hole test chassis 1 a plurality of test wells and the corresponding different heights puck 2, positioned on the disc 211 is provided with at least two stop holes 21, the positioning plate 2 is connected detachably to the chassis 1;; a thermocouple 11 includes a test and verification electrical galvanic 3 even 4, test 3 and even parity, respectively, passes through the galvanic limiting hole 4 is positioned within the test disc 2 is inserted into the hole 11 of the chassis 21 and a thermal process equipment.

[0034] In some embodiments, the chassis 1 is po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com