Drilling and punching integrated construction process of comb-shaped long drill hole in end-located drainage roadway

A construction technology and long drilling technology, which is applied in drilling equipment and methods, earthwork drilling, drilling equipment, etc., can solve the problems of large distance between coal-seeing points in branch holes and blind drainage areas, etc., so as to improve single-hole gas The effect of reducing the amount of extraction, accelerating the recovery rate of coal seam, and increasing the air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below. Obviously, the described embodiments are part of the embodiments of the present invention, rather than All the embodiments; based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative work all belong to the protection scope of the present invention.

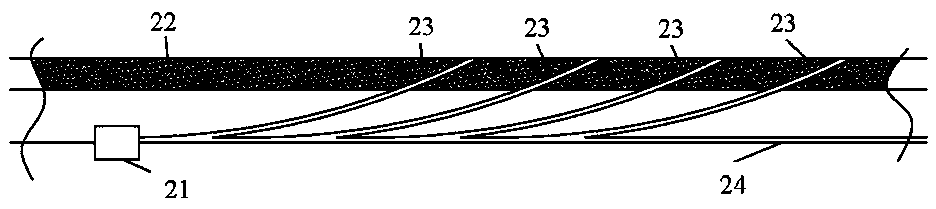

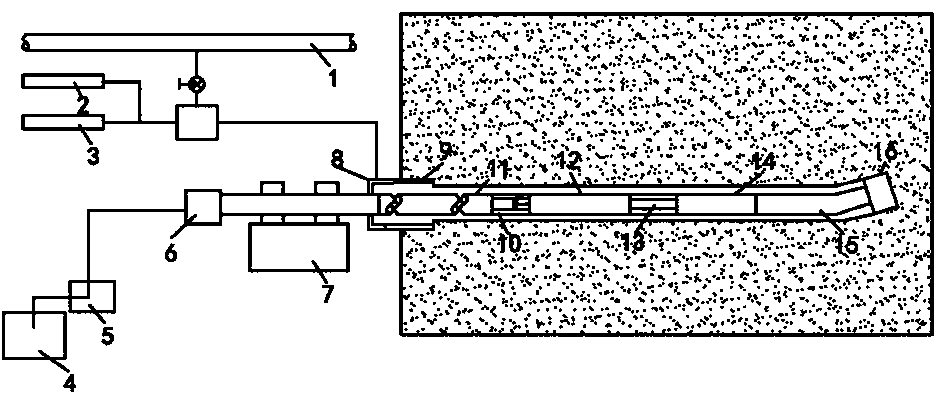

[0023] The embodiment of the present invention provides an integrated drilling and punching construction technology for comb-shaped long holes in the bottom pumping roadway, such as figure 1 As shown, in the embodiment of the present invention, the main hole is drilled at the bottom of the coal seam through the bottom pumping roadway, and a series of branch holes are drilled obliquely above the main hole. The post-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com