Pushing device and method for improving horizontal load-carrying performance of low bearing platform by pushing device

A jacking device and a jacking technology, which are applied in construction, infrastructure engineering, etc., can solve the problems of conservative and wasteful design of pile group foundations with low caps, achieve the goal of improving safety reserves, improve bearing capacity, and have a simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below, the present invention will be described in further detail in conjunction with the accompanying drawings.

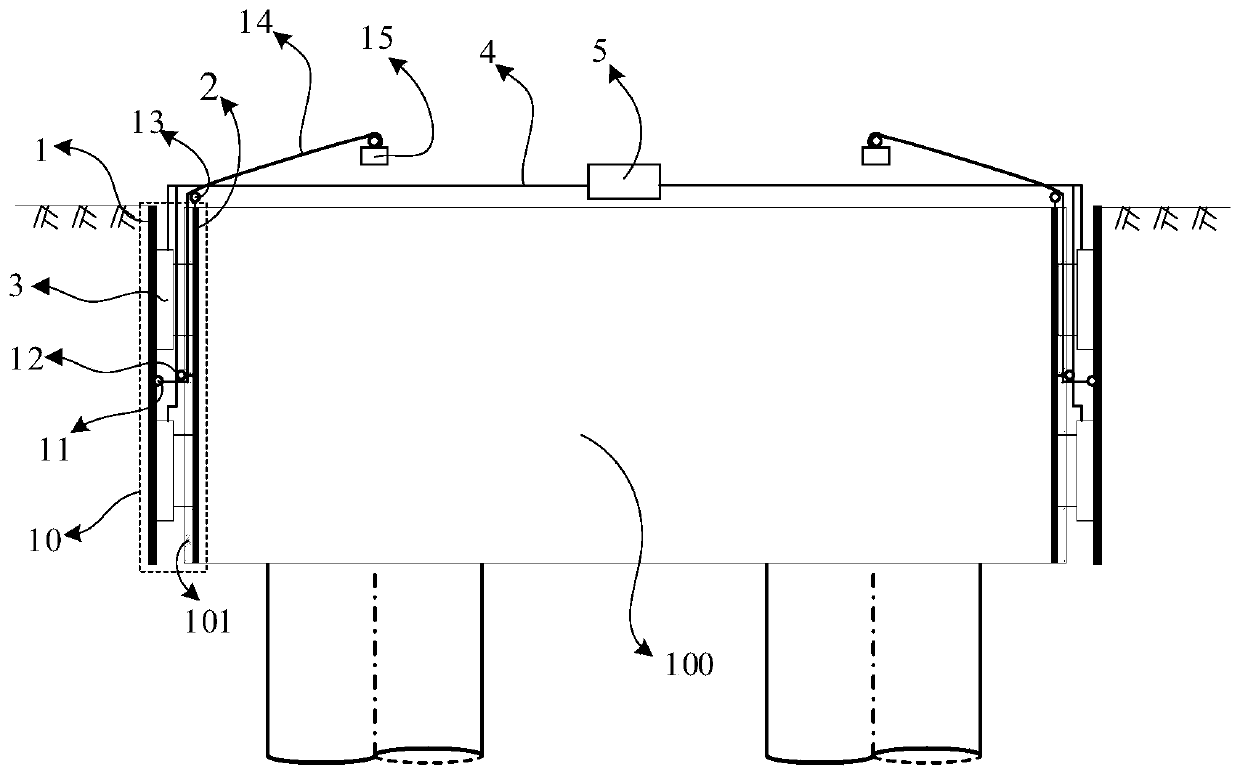

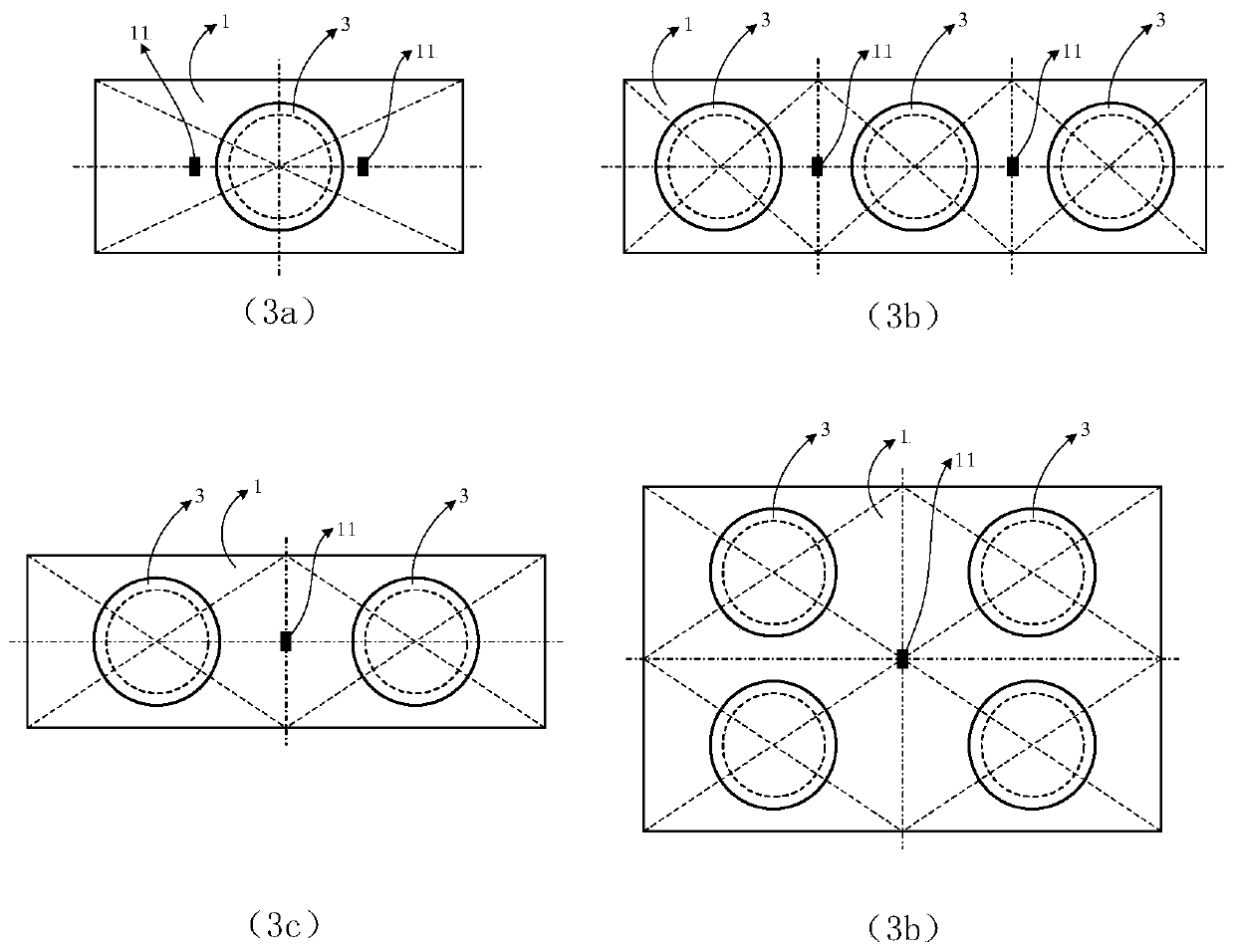

[0030] Such as figure 1 As shown, a pushing device disclosed in this embodiment includes two pushing assemblies 10, a driving device composed of a hydraulic oil pipe 4 and a hydraulic oil pump 5, and a reset device. Wherein, the two pushing assemblies 10 are respectively arranged on the two side walls of the low platform 100 in the direction of horizontal force. Both the driving device and the resetting device extend from the top of the lower platform to the pushing assembly 10 .

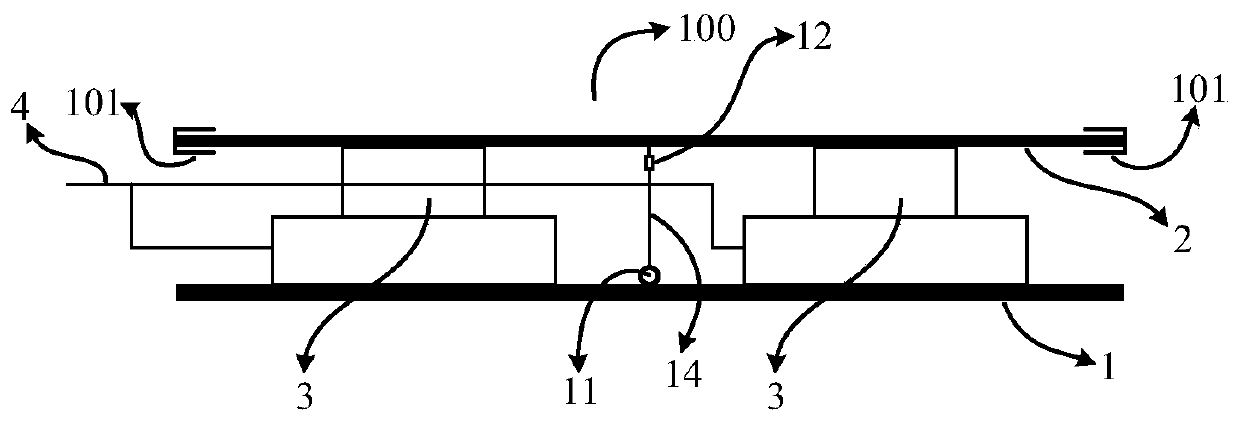

[0031] Please also refer to figure 2 The push assembly 10 includes a card slot fixed on the side wall of the low platform 100, a base 2 inserted into the slot, a push part 1 arranged in parallel on the outside of the base 2, and a push part 1 arranged on the base 2 and the push part. 1 is used to push the hydraulic cylinder 3 of the push part 1 outward.

[0032] Specifically,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com