A kind of nmp waste liquid recovery process

A waste liquid recovery and process technology, applied in organic chemistry and other directions, can solve the problems of process redundancy, high energy consumption and investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following is further described in detail through specific implementation methods:

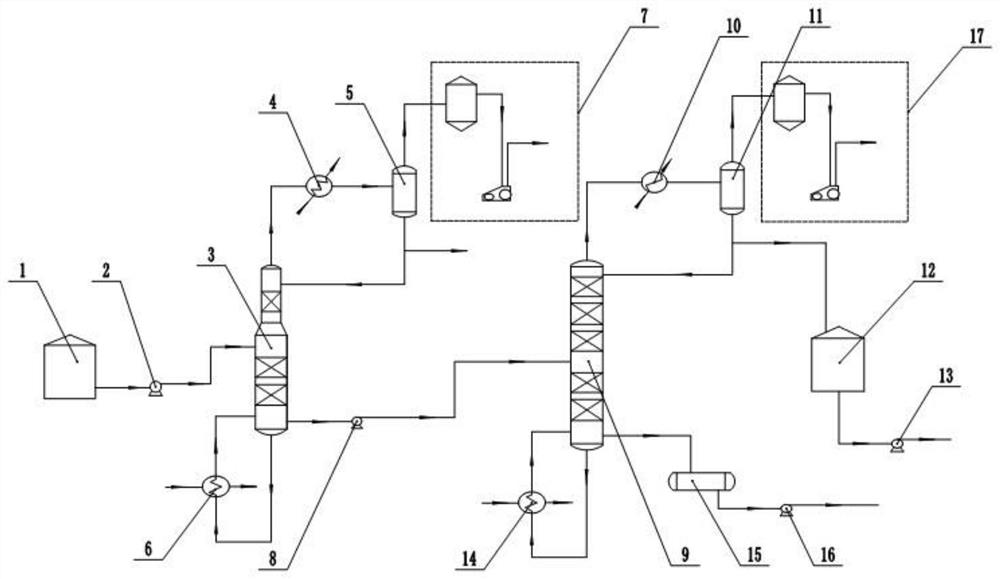

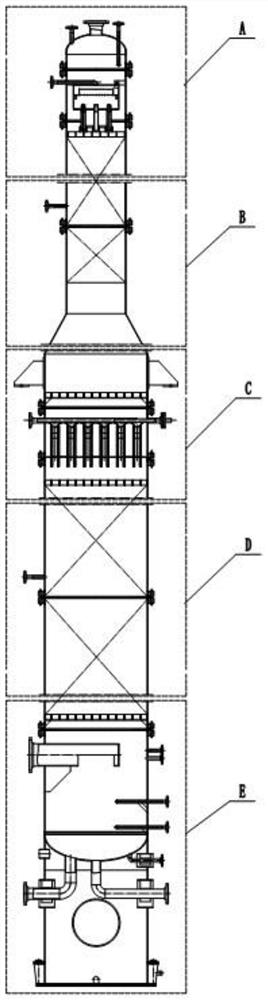

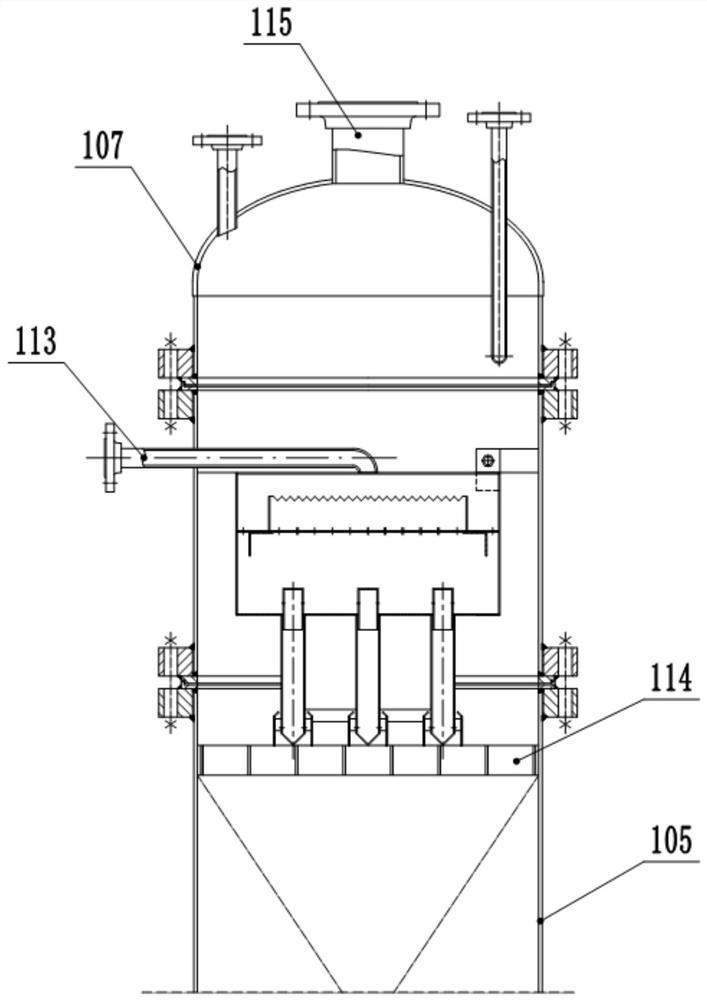

[0038] The reference signs in the drawings of the description include: waste liquid storage tank 1, first feed pump 2, vacuum dehydration tower 3, first condenser 4, first reflux tank 5, first reboiler 6, first vacuum System 7, second feed pump 8, product column 9, second condenser 10, second reflux tank 11, product storage tank 12, product pump 13, second reboiler 14, heavy component storage tank 15, heavy component Outgoing pump 16, second vacuum system 17, tower base 101, tower kettle 102, tower body 103, stripping section 104, rectifying section 105, conical section 106, tower top 107, discharge pipe 108, steam pipe 109 , Connecting pipe 110, feed pipe 111, discharge hole 112, return pipe 113, grid plate 114, air outlet 115, diversion bar 116, diversion groove 117.

[0039] combine figure 1 As shown in the flowchart, the equipment used in the embodiment includes a waste liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com