Normal-pressure electro-desalting backwashing wastewater treatment device

A wastewater treatment and treatment device technology, applied in the direction of heating water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of oil, water, slag separation, etc., to ensure COD The effect of indicators and separation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

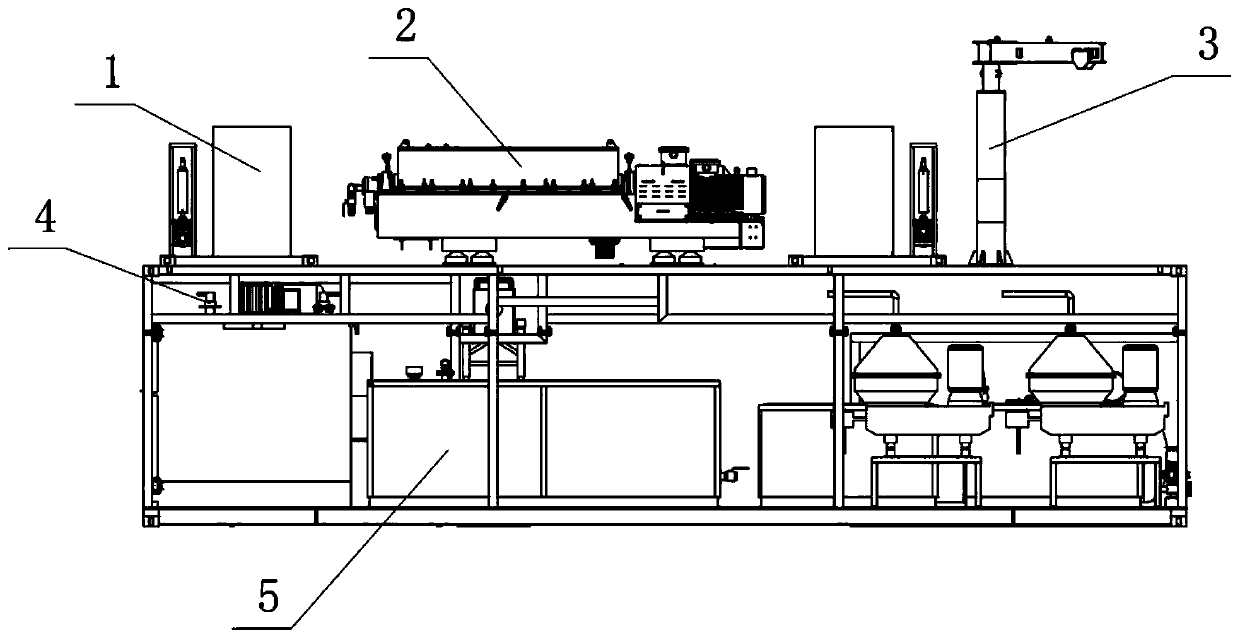

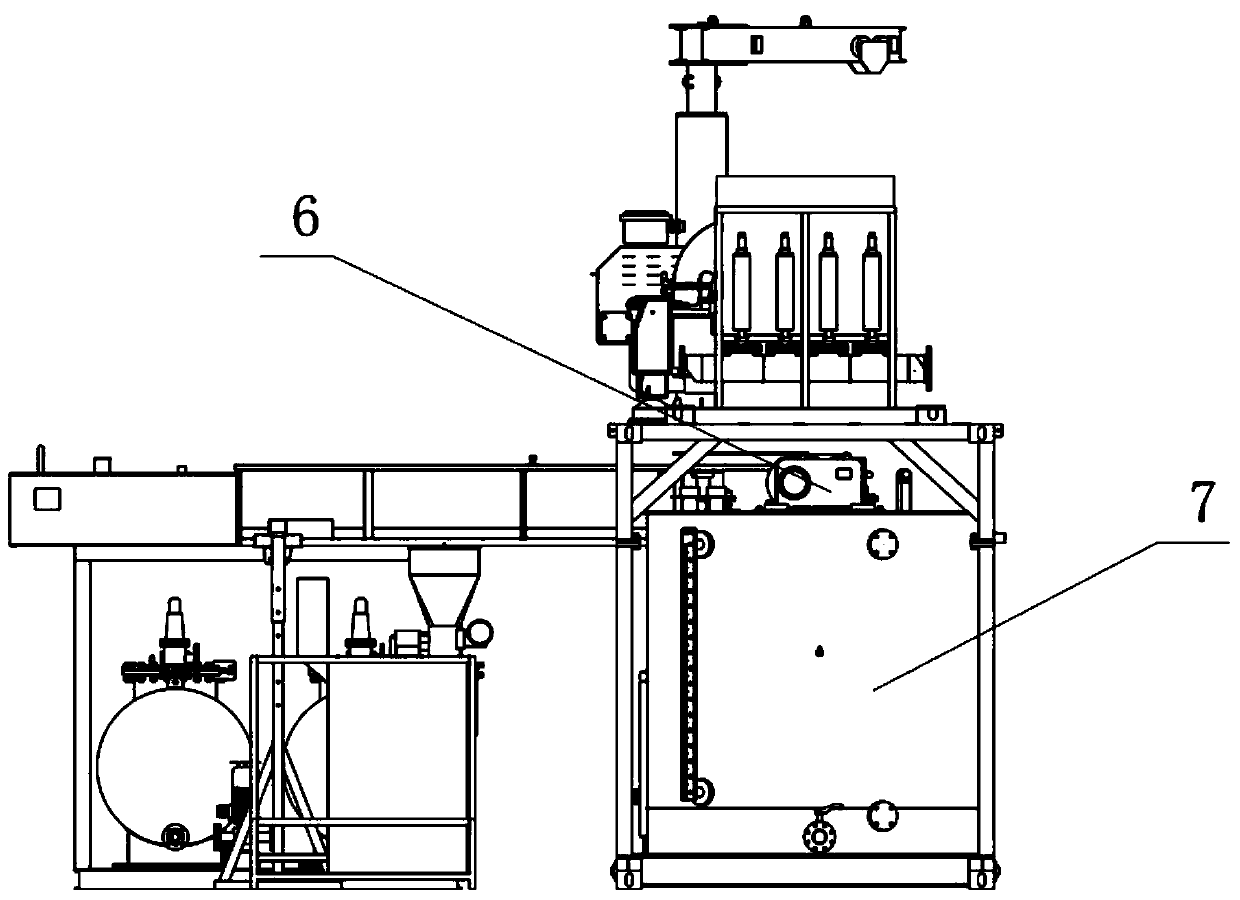

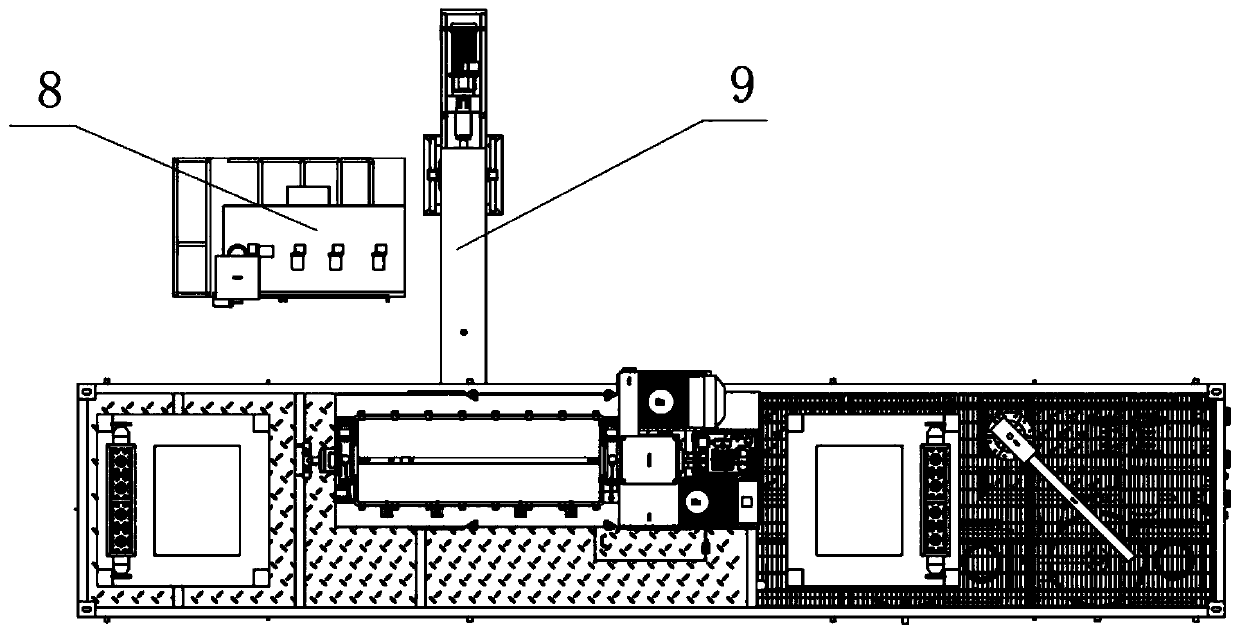

[0029] Combine below Figure 1-6 Description of this embodiment, an atmospheric pressure electric desalination backwash wastewater treatment device, including a thermal insulation buffer tank, a homogeneous discrete treatment skid, an ultrasonic synergistic circulation device, an ultrasonic multi-stage cavitation treatment device 1, a solid-liquid separation device 2, and a swash plate Settling device, liquid-liquid separation device and automatic control system, the thermal insulation buffer tank is connected to the homogeneous discrete processing skid, the homogeneous discrete processing skid is connected to the ultrasonic synergistic circulation device, and the homogeneous discrete processing skid is connected to the sonic multi-stage cavitation processing device Connection, the connection between the acoustic multi-stage cavitation treatment device and the solid-liquid separation device, the connection between the solid-liquid separation device and the inclined plate settli...

specific Embodiment approach 2

[0031] Combine below Figure 1-6 Describe this embodiment, this embodiment will further explain the first embodiment, the thermal insulation buffer tank is a vertical round tank, the thermal insulation buffer tank is provided with a liquid level display solenoid valve; the thermal insulation buffer tank process parameters: volume 130m 3 , With heat preservation function, with liquid level display function, overflow protection function.

specific Embodiment approach 3

[0033] Combine below Figure 1-6 Describe this embodiment, this embodiment will further explain the second embodiment, the homogeneous discrete processing skid includes 20m3 slurry tank, agitator 6, heating coil, rod type slurry pump, liquid level control and dosing module 8. The dosing module 8 is fixedly connected to one side of the homogeneous discrete processing skid; the flow rate of the agitator and the rod type slurry pump is 25m 3 , the tank volume of the discrete skid device is 15 cubic meters, the round tanks are in parallel structure, the dosing module 8 is fixed on one side of the homogeneous discrete processing skid, and there is a platform operation interface on the upper part of the homogeneous discrete processing skid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com