Curved surface polishing machine

A polishing machine and curved surface technology, applied in the field of polishing machines, can solve the problems of low processing efficiency, poor applicability, loss of resources, etc., and achieve the effect of high polishing efficiency, good applicability, and improved roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

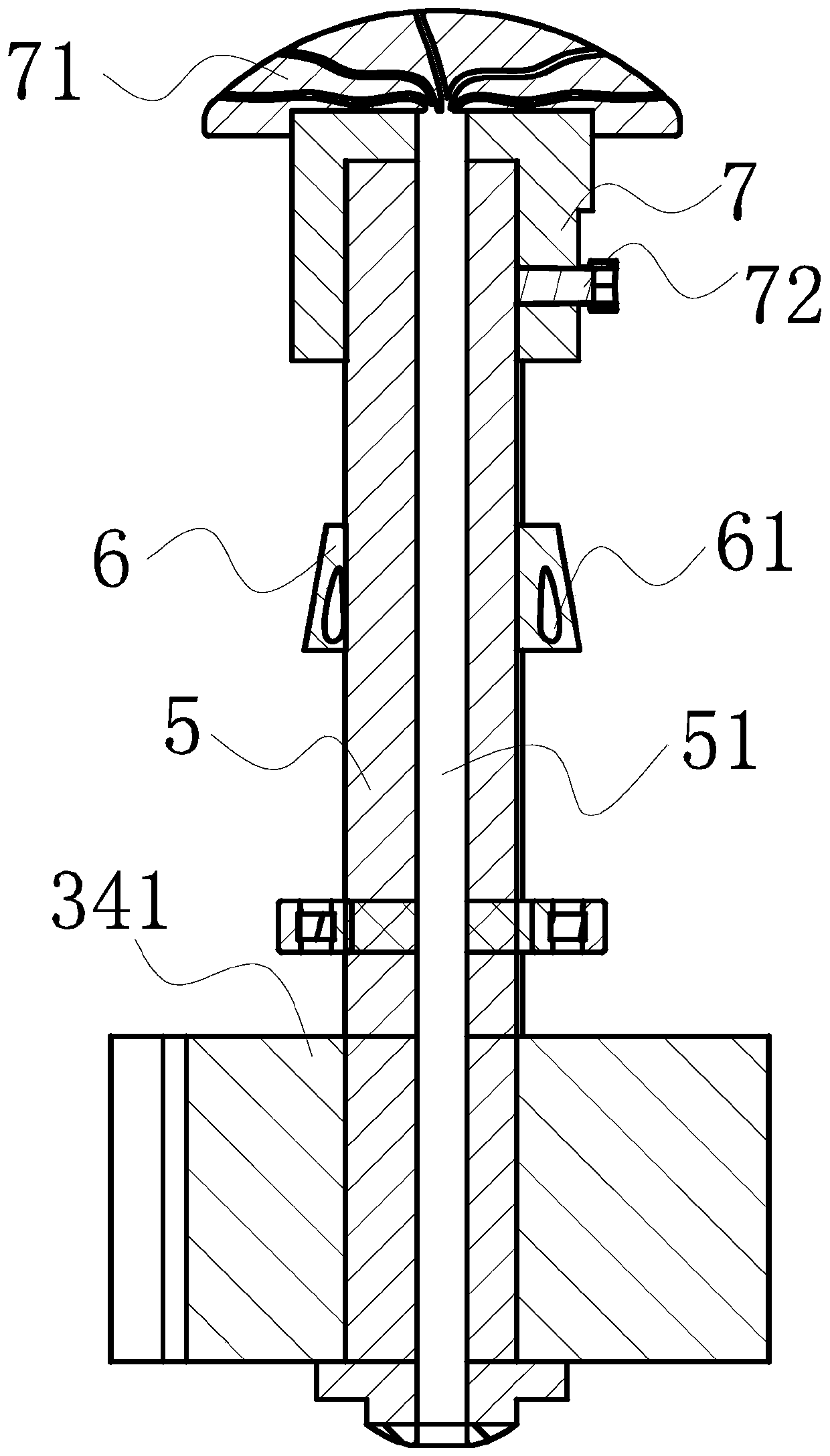

[0030] As an embodiment of the present invention, the inside of the spline shaft 5 is provided with a liquid guide hole 51; the grinding head 7 is fixedly installed on the upper end of the spline shaft 5 through a set screw 72; the top end of the grinding head 7 is fixedly connected There is a polishing cotton 71; the liquid guiding hole 51 is connected with the polishing cotton 71, and an external circulation pump pumps the polishing liquid into the polishing cotton 71 through the liquid guiding hole 51;

[0031] During work, the external circulating pump pumps the polishing liquid into the liquid guide hole 51 in the spline shaft 5 through the hose, and the polishing liquid enters the polishing cotton 71 through the liquid guide hole 51. When the grinding head 7 rotates, the polishing liquid From the micropores in the polishing cotton 71 to the polishing surface, the polishing liquid is thrown onto the polishing surface around the grinding head 7 under the centrifugal force g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com