Valve polishing device convenient to adjust for sewage treatment

A polishing device and sewage treatment technology, which is applied in the direction of grinding drive device, grinding/polishing equipment, surface polishing machine tool, etc., can solve the problems of wasting manpower and low efficiency, and achieve the effect of improving processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

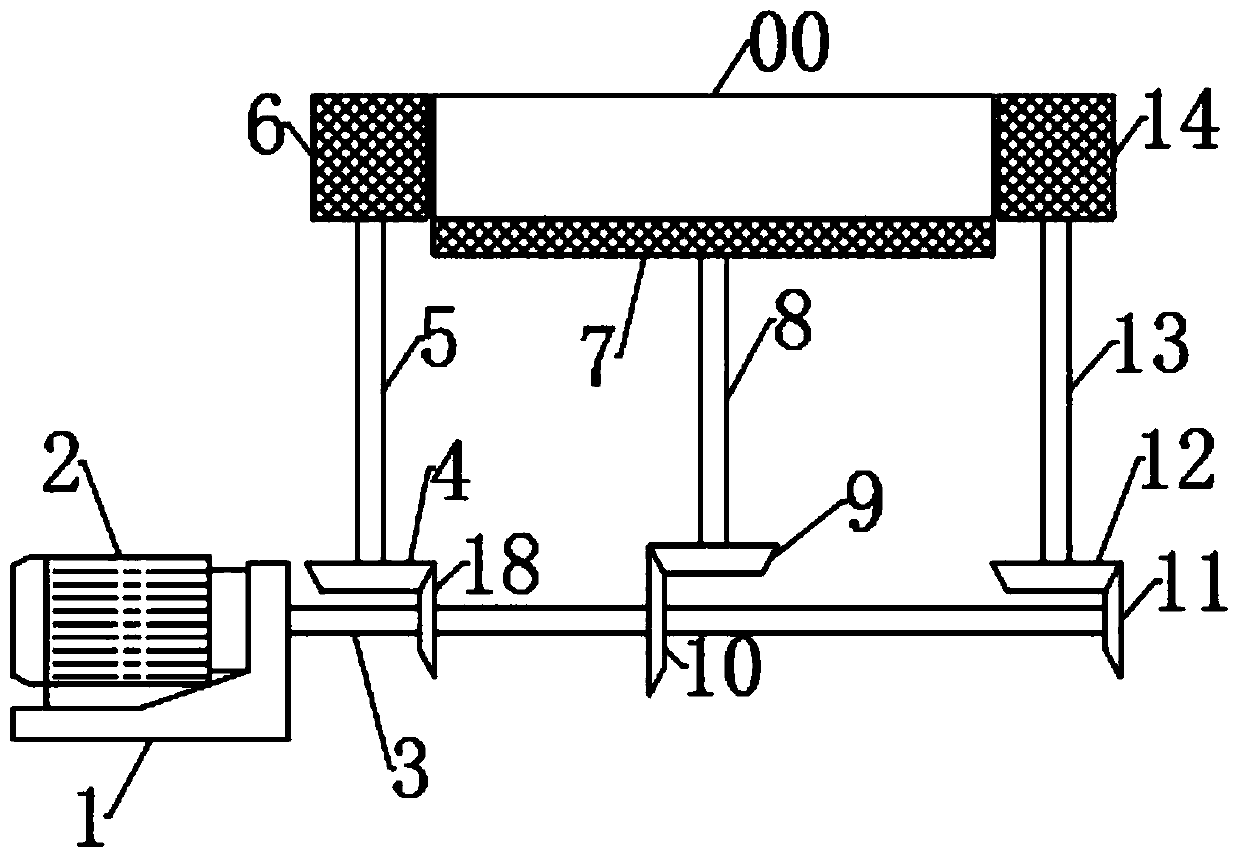

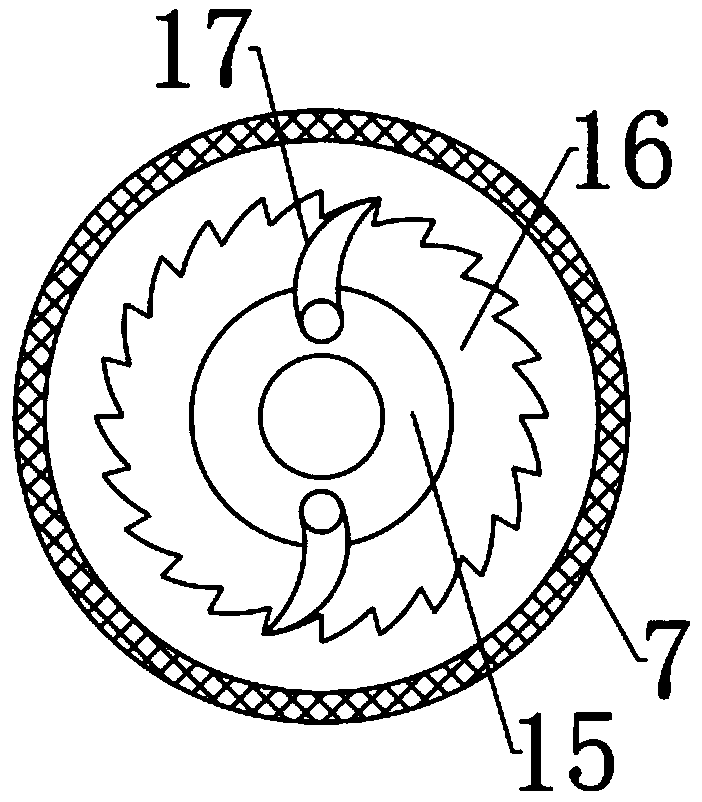

[0017] see Figure 1-3 , a valve polishing device for sewage treatment that is easy to adjust, including a workbench 7, on which a valve 00 to be polished is placed, the workbench 7 is connected with a power mechanism that can make it rotate, and a polishing wheel-6 is arranged on both sides and polishing wheel 2 14; polishing wheel 1 6 and polishing wheel 2 14 are connected to the power mechanism and are located at the edges of both sides of the valve 00.

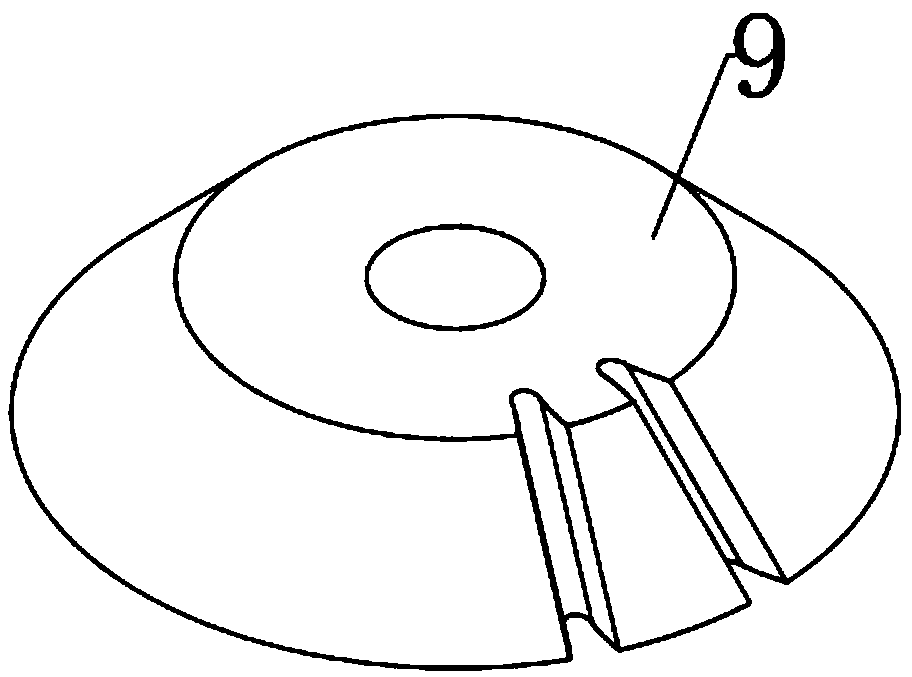

[0018] The specific structure of the power mechanism is not limited, preferably, in the present embodiment, the power mechanism includes a base 1, a motor 2 is arranged on the base 1, and the motor 2 is connected to the drive shaft 3; Helical gear 3 18, helical gear 1 10 and helical gear 2 11 are arranged at intervals, and an intermittent wheel 9 meshing with it is arranged above the helical gear 10, and the intermittent wheel 9 is connected with the rotating shaft 8, and the other end of the rotating shaft 8 It is fixedl...

Embodiment 2

[0025] In embodiment 1, the wall surface of polishing wheel 1 6 and polishing wheel 2 14 is the working contact surface, and greater wear will occur during the working process. If things go on like this, it will affect the polishing precision of valve 00; therefore, this embodiment is in Improvements are made on the basis of Example 1. The improvements are: under the premise of ensuring the machining accuracy, the walls of polishing wheel one 6 and polishing wheel two 14 are plated with a wear-resistant coating to slow down the process of polishing wheel one 6 and polishing wheel two. The wear rate of 214 prolongs the service life of the whole device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com