Modular installation method for thin-frame sliding door and window

A technology of sliding doors and windows and installation methods, which is applied in the field of doors and windows, can solve the problems of poor durability of locking devices, inability to align locking rods, and lack of fine-tuning functions, etc., so as to prevent loosening, prevent processing traces, expose lower pulleys, and increase the appearance. bokeh effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] see Figure 1 to Figure 24 As shown, a modular installation method of a thin frame sliding door and window of the present invention includes a modular production process and an on-site installation process;

[0057] The modular production process includes:

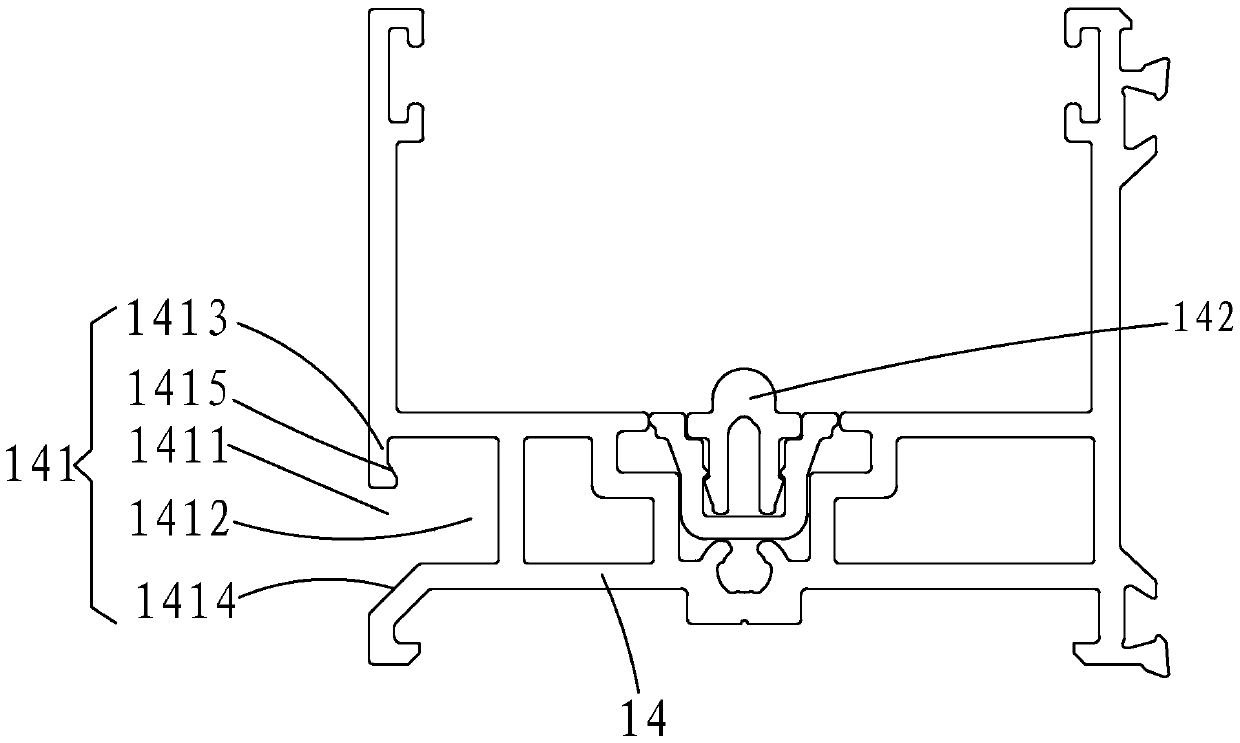

[0058]Step 11: Preparation step, prepare door frame profiles 1, at least one push-pull fan 3, plural dust-proof sealing parts 8, plural glass centering blocks 4, plural lower pulley devices 5 corresponding to the quantity of push-pull fans 3, plural corresponding to the quantity of push-pull fans 3 The upper pulley block device 6, at least one locking device 7, two waterproof blocking parts 2, EPDM rubber strip 9 and rubber strip 10; the door frame profile 1 includes a left frame 11, a right frame 12, an upper frame 13 and a lower frame 14 , the outer side of the lower frame 14 is concavely provided with a splash-proof groove 141, the longitudinal section of the splash-proof groove 141 is a groove 1412 with an open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com