Cement pavement maintenance device

A cement pavement and water tank technology, which is applied in the direction of roads, roads, road repairs, etc., can solve problems affecting the construction schedule, cement pavement damage, time-consuming and labor-intensive problems, and achieve the effects of improving laying efficiency, saving water, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

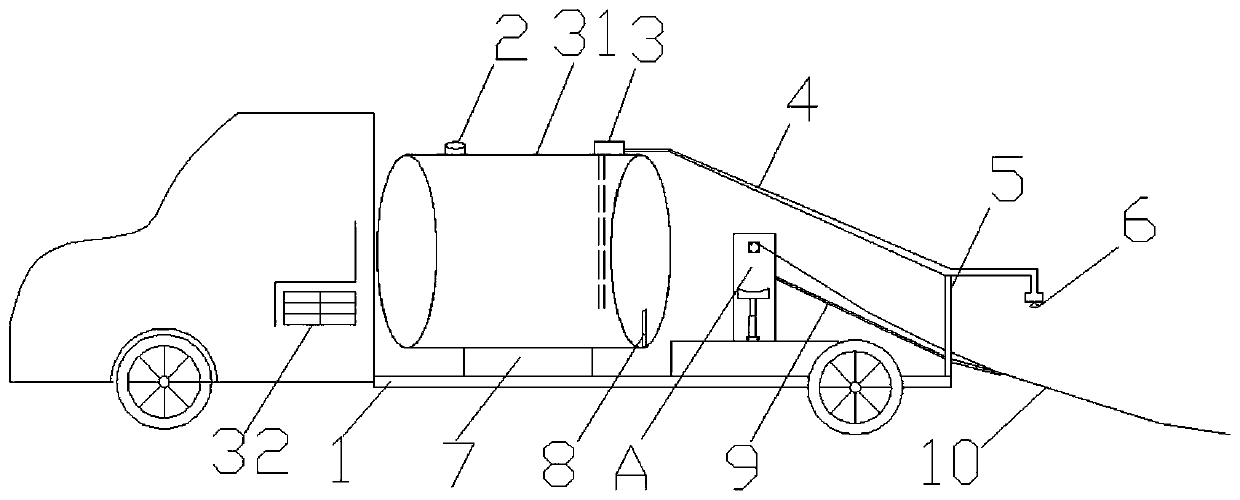

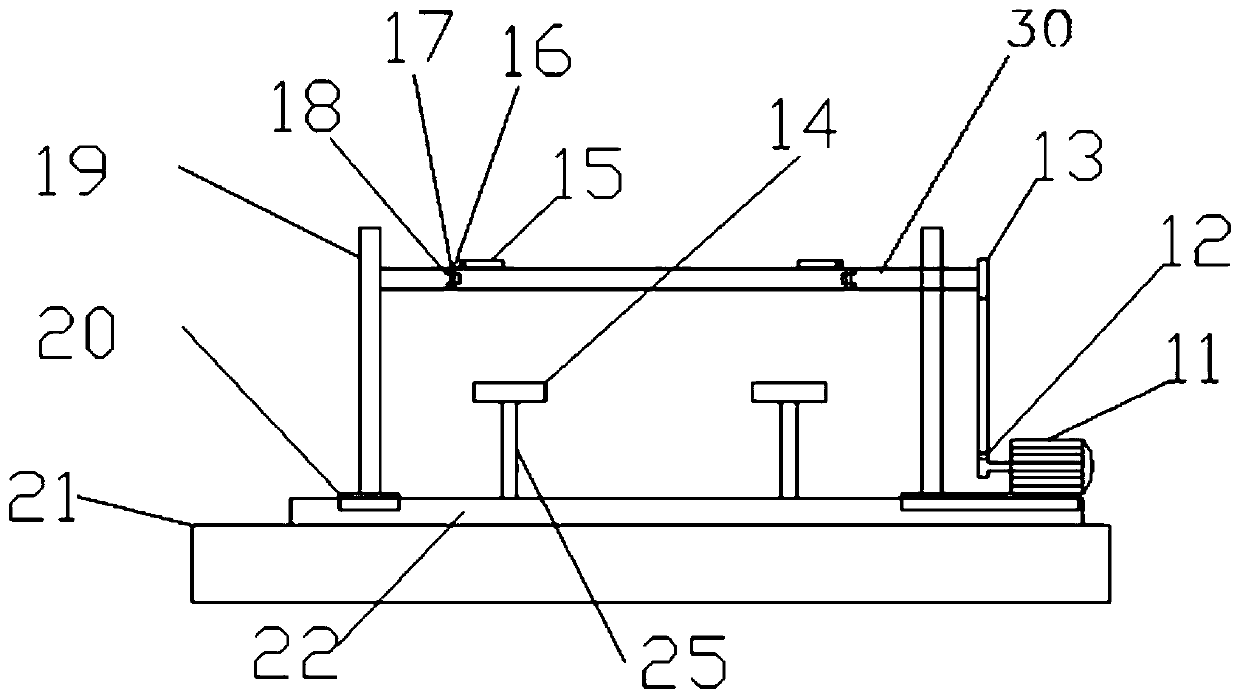

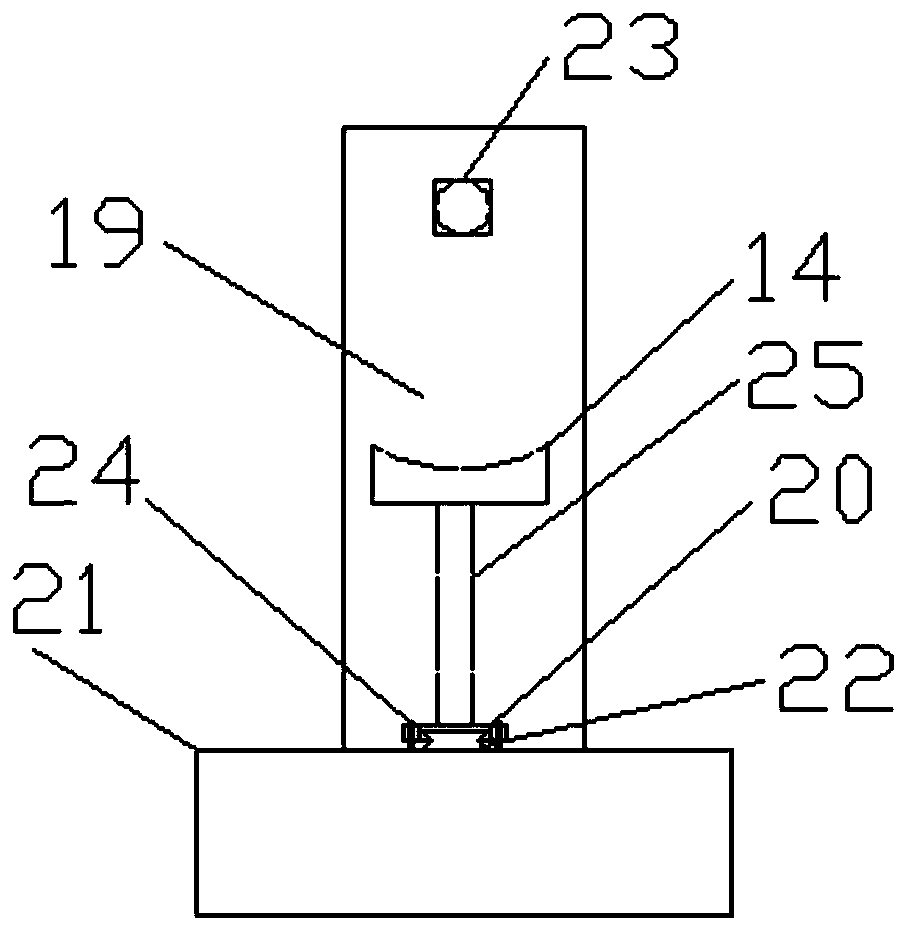

[0031] The present invention is described in further detail below in conjunction with accompanying drawing:

[0032] refer to figure 1 The "front" and "rear" of the present invention are explained with reference to the driving direction of the tractor for convenience. The cement road maintenance device of the present invention includes a first base 1, a water tank 31 and a storage battery 32. The first The base 1 is arranged on the vehicle frame of the tractor, the water tank 31 is arranged on the top of the first base 1, the top of the water tank 31 is provided with a water storage port 2, the top of the rear end of the water tank 31 is provided with a water pump 3, and the water inlet pipe of the water pump 3 extends into At the bottom of the water tank 31, the outlet pipe of the water pump 3 is connected with a nozzle 6; the nozzle 6 is arranged at the rear end of the tractor; the first base 1 is also provided with a health-preserving cloth rolling device, and the health-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com