Special color master batch for antibacterial sanitary material fibers, and preparation method thereof

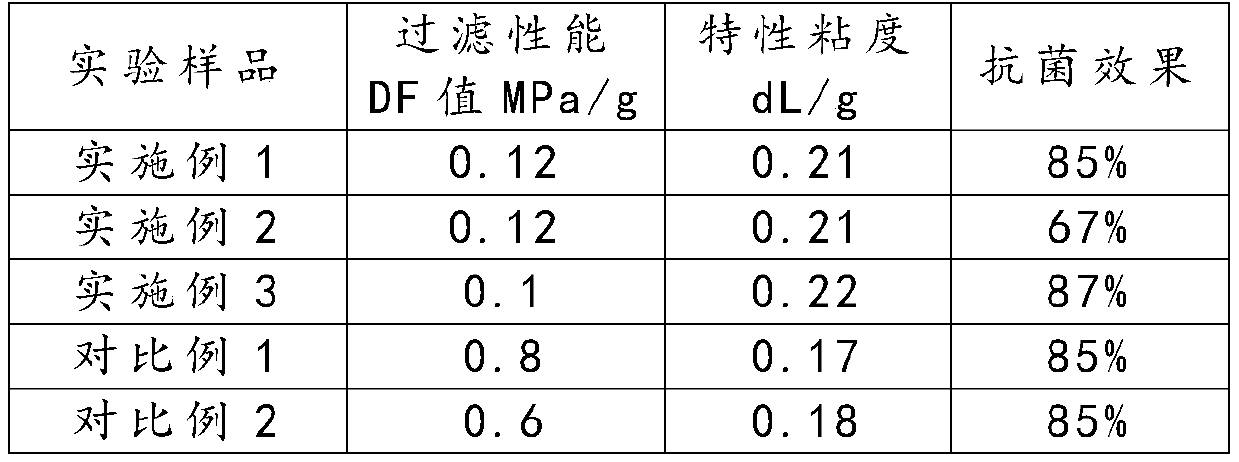

A color masterbatch and fiber technology, applied in the field of sanitary materials auxiliary materials, can solve the problems of short component replacement cycle, poor dispersibility, insufficient whiteness, etc., and achieve the effects of favorable industrialization promotion, good filtration performance, and good antibacterial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] White masterbatch formula: 39% of bottle-grade PET polyester chips with an intrinsic viscosity of 0.82dL / g, 1% of calcium stearate, 60% of Japanese Fuji titanium dioxide TA301, and 5% of silver zeolite antibacterial agent.

[0024] Preparation method: mix each component according to the mass ratio, then mix in a high-speed mixer, and then use a twin-screw extruder to melt and blend, granulate, dry, and pack to obtain the special color masterbatch for antibacterial health material fiber. Among them, the temperature conditions of twin-screw extruder melt blending are: 240°C in zone 1, 260°C in zone 2, 265°C in zone 3, 260°C in zone 4, 255°C in zone 5, 250°C in zone 6, 250°C in zone 7, Zone 8: 250°C, Zone 9: 240°C, Zone 10: 240°C, Head temperature: 260°C.

Embodiment 2

[0026] 39% of bottle-grade PET polyester chips with an intrinsic viscosity of 0.82dL / g, 1% of calcium stearate, 60% of Japanese Fuji titanium dioxide TA301, and 4% of silver zeolite antibacterial agent.

[0027] Preparation method: same as Example 1.

Embodiment 3

[0029] White masterbatch formula: 39% of bottle-grade PET polyester chips with an intrinsic viscosity of 0.82dL / g, 1% of calcium stearate, 60% of Japanese Fuji titanium dioxide TA301, 5% of silver zeolite antibacterial agent, and 1% of silane coupling agent .

[0030] Preparation method: same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com