Regenerated composite admixture utilizing construction waste and preparation method thereof

A technology of compound admixture and construction waste, applied in the field of construction waste recycling, can solve the problem of less than 5% recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

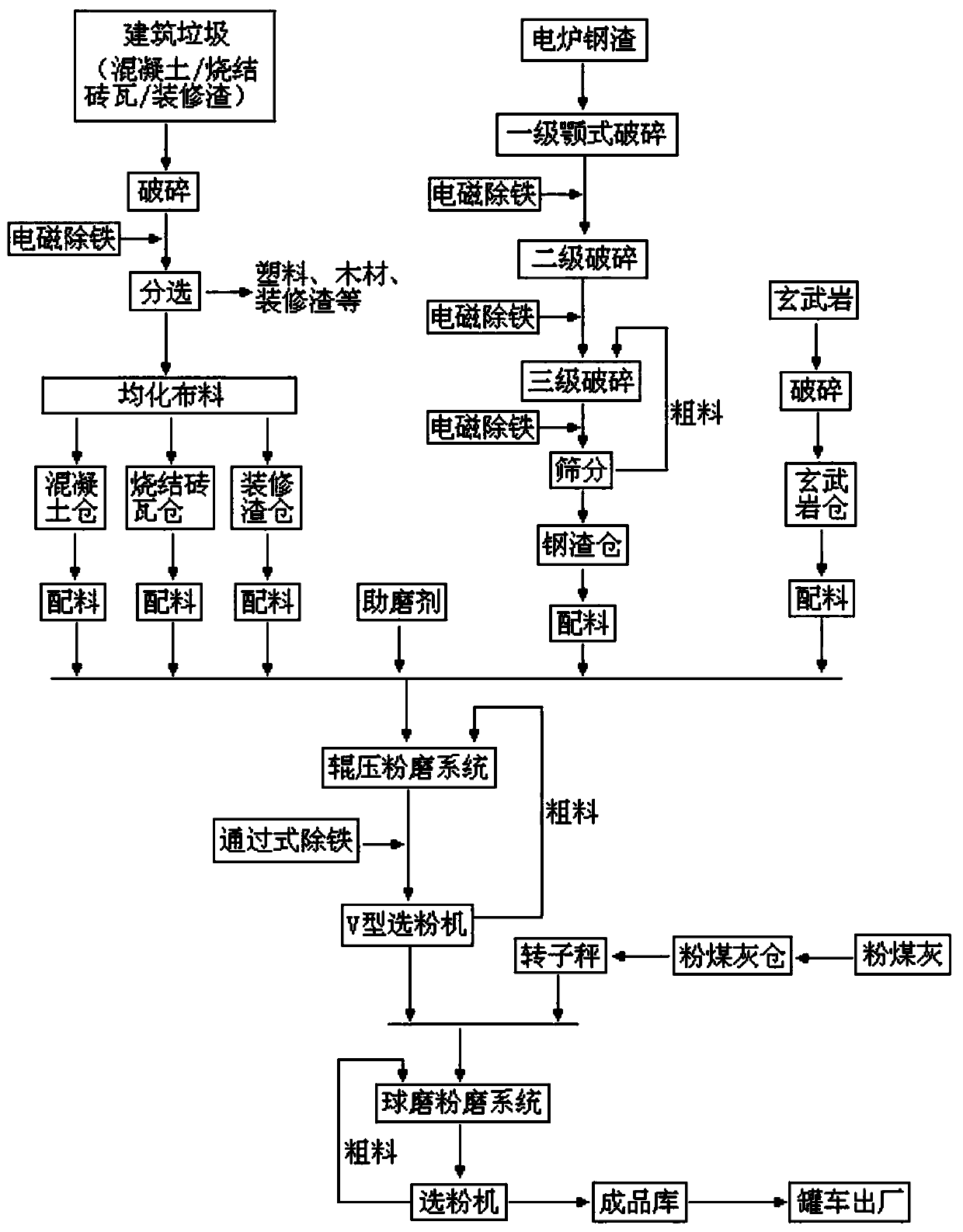

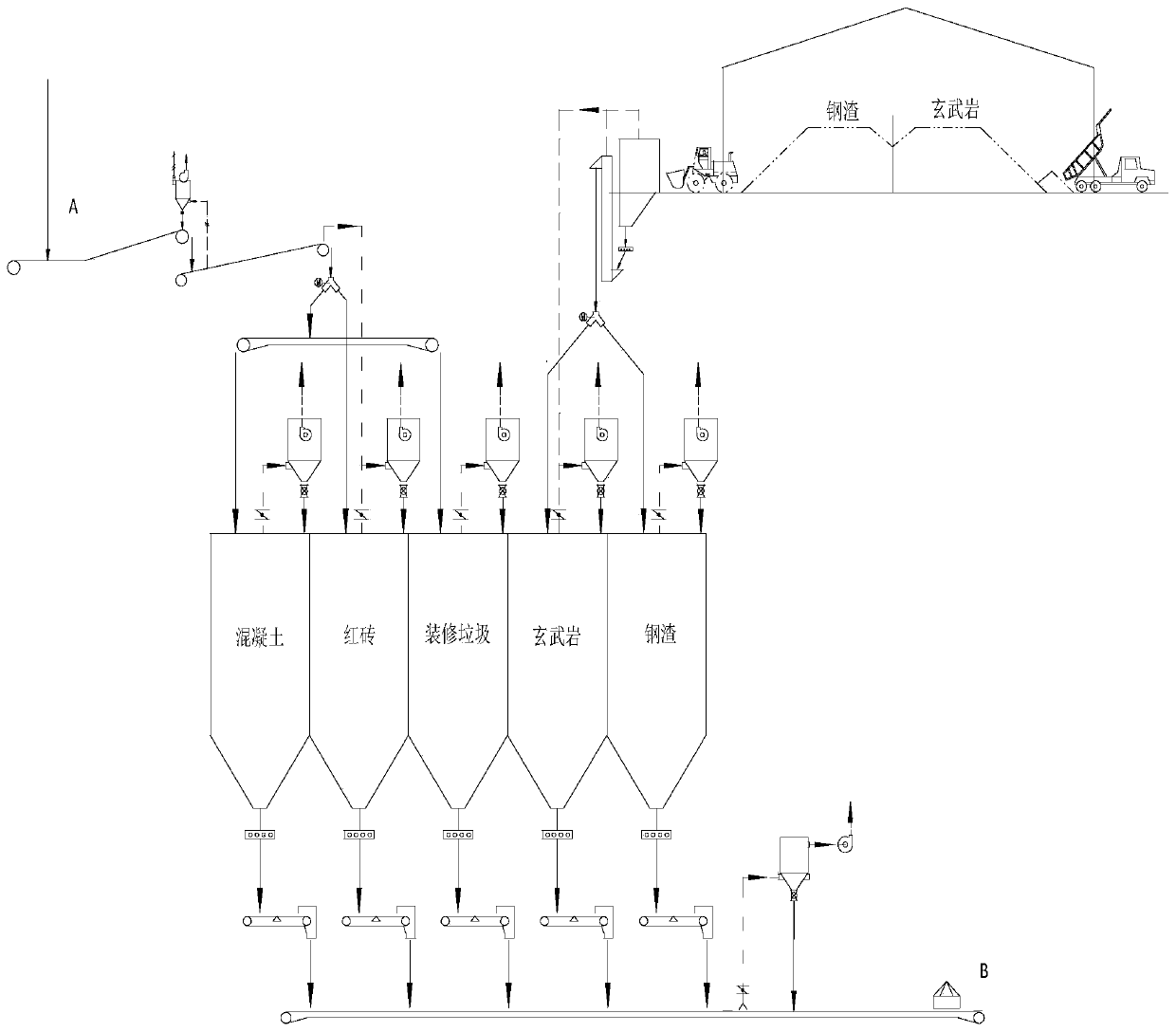

[0047] Such as Figure 1 to Figure 6 As shown, in this embodiment, a renewable composite admixture using construction waste and a preparation method thereof are made from the following raw materials in parts by weight: 30 parts of concrete, 40 parts of sintered bricks, 10 parts of decoration slag, 5 parts of pulverized coal Ash, 10 parts of electric furnace steel slag, 5 parts of basalt and 0.125 parts of grinding aid. The preparation process is described in detail below:

[0048] (1) Raw material pretreatment:

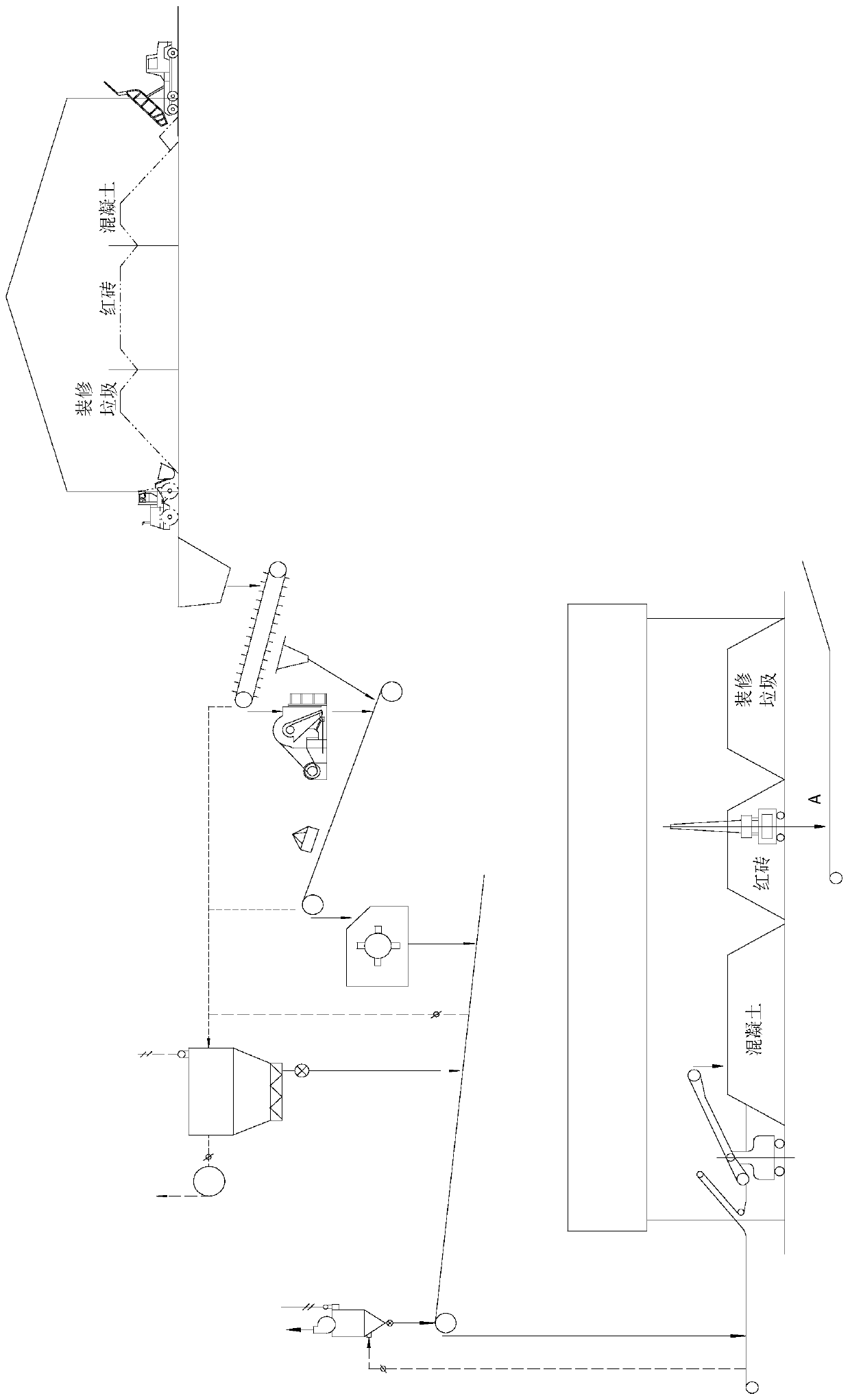

[0049] (1) Pretreatment of construction waste: crushing, removing iron and screening construction waste to obtain construction waste particles with a diameter of 20-50 mm; among them, construction waste is divided into concrete, sintered bricks and tiles, and decoration slag. In this embodiment, the construction waste is crushed and impurity-removed. The crushed building slag particles with a particle size of 20-50 mm are transported to the silo for storage by the homoge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com